Nondestructive testing (NDT) is any of a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage. The terms nondestructive examination (NDE), nondestructive inspection (NDI), and nondestructive evaluation (NDE) are also commonly used to describe this technology. Because NDT does not permanently alter the article being inspected, it is a highly valuable technique that can save both money and time in product evaluation, troubleshooting, and research. The six most frequently used NDT methods are eddy-current, magnetic-particle, liquid penetrant, radiographic, ultrasonic, and visual testing. NDT is commonly used in forensic engineering, mechanical engineering, petroleum engineering, electrical engineering, civil engineering, systems engineering, aeronautical engineering, medicine, and art. Innovations in the field of nondestructive testing have had a profound impact on medical imaging, including on echocardiography, medical ultrasonography, and digital radiography.

An inspection is, most generally, an organized examination or formal evaluation exercise. In engineering activities inspection involves the measurements, tests, and gauges applied to certain characteristics in regard to an object or activity. The results are usually compared to specified requirements and standards for determining whether the item or activity is in line with these targets, often with a Standard Inspection Procedure in place to ensure consistent checking. Inspections are usually non-destructive.

Dye penetrant inspection (DP), also called liquid penetrate inspection (LPI) or penetrant testing (PT), is a widely applied and low-cost inspection method used to check surface-breaking defects in all non-porous materials. The penetrant may be applied to all non-ferrous materials and ferrous materials, although for ferrous components magnetic-particle inspection is often used instead for its subsurface detection capability. LPI is used to detect casting, forging and welding surface defects such as hairline cracks, surface porosity, leaks in new products, and fatigue cracks on in-service components.

Magnetic particle inspection (MPI) is a nondestructive testing process where a magnetic field is used for detecting surface, and shallow subsurface, discontinuities in ferromagnetic materials. Examples of ferromagnetic materials include iron, nickel, cobalt, and some of their alloys. The process puts a magnetic field into the part. The piece can be magnetized by direct or indirect magnetization. Direct magnetization occurs when the electric current is passed through the test object and a magnetic field is formed in the material. Indirect magnetization occurs when no electric current is passed through the test object, but a magnetic field is applied from an outside source. The magnetic lines of force are perpendicular to the direction of the electric current, which may be either alternating current (AC) or some form of direct current (DC).

Plastic welding is welding for semi-finished plastic materials, and is described in ISO 472 as a process of uniting softened surfaces of materials, generally with the aid of heat. Welding of thermoplastics is accomplished in three sequential stages, namely surface preparation, application of heat and pressure, and cooling. Numerous welding methods have been developed for the joining of semi-finished plastic materials. Based on the mechanism of heat generation at the welding interface, welding methods for thermoplastics can be classified as external and internal heating methods, as shown in Fig 1.

In engineering, damage tolerance is a property of a structure relating to its ability to sustain defects safely until repair can be effected. The approach to engineering design to account for damage tolerance is based on the assumption that flaws can exist in any structure and such flaws propagate with usage. This approach is commonly used in aerospace engineering, mechanical engineering, and civil engineering to manage the extension of cracks in structure through the application of the principles of fracture mechanics. A structure is considered to be damage tolerant if a maintenance program has been implemented that will result in the detection and repair of accidental damage, corrosion and fatigue cracking before such damage reduces the residual strength of the structure below an acceptable limit.

In pipeline transportation, pigging is the practice of using pipeline inspection gauges or gadgets, devices generally referred to as pigs or scrapers, to perform various maintenance operations. This is done without stopping the flow of the product in the pipeline.

Failure analysis is the process of collecting and analyzing data to determine the cause of a failure, often with the goal of determining corrective actions or liability. According to Bloch and Geitner, ”machinery failures reveal a reaction chain of cause and effect… usually a deficiency commonly referred to as the symptom…”. Failure analysis can save money, lives, and resources if done correctly and acted upon. It is an important discipline in many branches of manufacturing industry, such as the electronics industry, where it is a vital tool used in the development of new products and for the improvement of existing products. The failure analysis process relies on collecting failed components for subsequent examination of the cause or causes of failure using a wide array of methods, especially microscopy and spectroscopy. Nondestructive testing (NDT) methods are valuable because the failed products are unaffected by analysis, so inspection sometimes starts using these methods.

Eddy-current testing is one of many electromagnetic testing methods used in nondestructive testing (NDT) making use of electromagnetic induction to detect and characterize surface and sub-surface flaws in conductive materials.

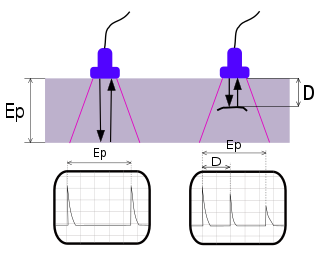

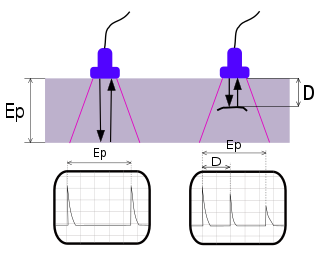

Ultrasonic testing (UT) is a family of non-destructive testing techniques based on the propagation of ultrasonic waves in the object or material tested. In most common UT applications, very short ultrasonic pulse waves with centre frequencies ranging from 0.1-15 MHz and occasionally up to 50 MHz, are transmitted into materials to detect internal flaws or to characterize materials. A common example is ultrasonic thickness measurement, which tests the thickness of the test object, for example, to monitor pipework corrosion and erosion. Ultrasonic testing is extensively used to detect flaws in welds.

Conformal coating is a protective, breathable coating of thin polymeric film applied to printed circuit boards (PCBs). Conformal coatings are typically applied at 25–250 μm to the electronic circuitry and provide protection against moisture and other harsher conditions.

Rail inspection is the practice of examining rail tracks for flaws that could lead to catastrophic failures. According to the United States Federal Railroad Administration Office of Safety Analysis, track defects are the second leading cause of accidents on railways in the United States. The leading cause of railway accidents is attributed to human error. The contribution of poor management decisions to rail accidents caused by infrequent or inadequate rail inspection is significant but not reported by the FRA, only the NTSB. Every year, North American railroads spend millions of dollars to inspect the rails for internal and external flaws. Nondestructive testing (NDT) methods are used as preventive measures against track failures and possible derailment.

Thermographic inspection refers to the nondestructive testing (NDT) of parts, materials or systems through the imaging of the temperature fields, gradients and/or patterns ("thermograms") at the object's surface. It is distinguished from medical thermography by the subjects being examined: thermographic inspection generally examines inanimate objects, while medical thermography generally examines living organisms. Generally, thermographic inspection is performed using an infrared sensor.

Hot plate welding, also called heated tool welding, is a thermal welding technique for joining thermoplastics. A heated tool is placed against or near the two surfaces to be joined in order to melt them. Then, the heat source is removed, and the surfaces are brought together under pressure. Hot plate welding has relatively long cycle times, ranging from 10 seconds to minutes, compared to vibration or ultrasonic welding. However, its simplicity and ability to produce strong joints in almost all thermoplastics make it widely used in mass production and for large structures, like large-diameter plastic pipes. Different inspection techniques are implemented in order to identify various discontinuities or cracks.

Active thermography is an advanced nondestructive testing procedure, which uses a thermography measurement of a tested material thermal response after its external excitation. This principle can be used also for non-contact infrared non-destructive testing (IRNDT) of materials.

The Day-Glo Color Corp. is a privately held American paint and pigments manufacturer based in Cleveland, Ohio. It was founded in 1946 by brothers Joseph and Robert Switzer and is currently owned by RPM International. It specializes in fluorescent paint and pigments, such as those used in safety applications, artwork and signage. It invented black-light fluorescent and daylight fluorescent paints and nondestructive testing methods using fluorescent dyes.

Transportable pressure vessels for high-pressure gases are routinely inspected and tested as part of the manufacturing process. They are generally marked as evidence of passing the tests, either individually or as part of a batch, and certified as meeting the standard of manufacture by the authorised testing agency, making them legal for import and sale. When a cylinder is manufactured, its specification, including manufacturer, working pressure, test pressure, date of manufacture, capacity and weight are stamped on the cylinder.

A cascade chart is tool that can be used in damage tolerance analysis to determine the proper inspection interval, based on reliability analysis, considering all the context uncertainties. The chart is called a "cascade chart" because the scatter of data points and downward curvature resembles a waterfall or cascade. This name was first introduced by Dr. Alberto W Mello in his work "Reliability prediction for structures under cyclic loads and recurring inspections". Materials subject to cyclic loads, as shown in the graph on the right, may form and propagate cracks over time due to fatigue. Therefore, it is essential to determine a reliable inspection interval. There are numerous factors that must be considered to determine this inspection interval. The non-destructive inspection (NDI) technique must have a high probability of detecting a crack in the material. If missed, a crack may lead the structure to a catastrophic failure before the next inspection. On the other hand, the inspection interval cannot be too frequent that the structure's maintenance is no longer profitable.

Dye-n-Pry, also called Dye And Pry, Dye and Pull, Dye Staining, or Dye Penetrant, is a destructive analysis technique used on surface mount technology (SMT) components to either perform failure analysis or inspect for solder joint integrity. It is an application of dye penetrant inspection.