Related Research Articles

Inventory or stock refers to the goods and materials that a business holds for the ultimate goal of resale, production or utilisation.

A supply chain is a complex logistics system that consists of facilities that convert raw materials into finished products which are later distributed to end consumers or end customers. Meanwhile, supply chain management deals with the flow of goods within the supply chain in the most efficient manner.

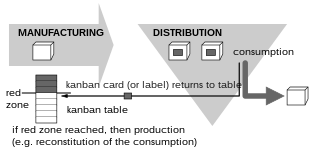

Kanban is a scheduling system for lean manufacturing. Taiichi Ohno, an industrial engineer at Toyota, developed kanban to improve manufacturing efficiency. The system takes its name from the cards that track production within a factory. Kanban is also known as the Toyota nameplate system in the automotive industry.

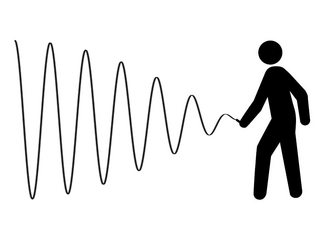

The beer distribution game is an educational game that is used to experience typical coordination problems of a supply chain process. It reflects a role-play simulation where several participants play with each other. The game represents a supply chain with a non-coordinated process where problems arise due to lack of information sharing. This game outlines the importance of information sharing, supply chain management and collaboration throughout a supply chain process. Due to lack of information, suppliers, manufacturers, sales people and customers often have an incomplete understanding of what the real demand of an order is. The most interesting part of the game is that each group has no control over another part of the supply chain. Therefore, each group has only significant control over their own part of the supply chain. Each group can highly influence the entire supply chain by ordering too much or too little which can lead to a bullwhip effect. Therefore, the order taking of a group also highly depends on decisions of the other groups.

Operations management is an area of management concerned with designing and controlling the process of production and redesigning business operations in the production of goods or services. It involves the responsibility of ensuring that business operations are efficient in terms of using as few resources as needed and effective in meeting customer requirements.

Demand management is a planning methodology used to forecast, plan for and manage the demand for products and services. This can be at macro-levels as in economics and at micro-levels within individual organizations. For example, at macro-levels, a government may influence interest rates to regulate financial demand. At the micro-level, a cellular service provider may provide free night and weekend use to reduce demand during peak hours.

Safety stock is a term used by logisticians to describe a level of extra stock that is maintained to mitigate risk of stockouts caused by uncertainties in supply and demand. Adequate safety stock levels permit business operations to proceed according to their plans. Safety stock is held when uncertainty exists in demand, supply, or manufacturing yield, and serves as an insurance against stockouts.

Inventory control or stock control can be broadly defined as "the activity of checking a shop's stock". It is the process of ensuring that the right amount of supply is available within a business. However, a more focused definition takes into account the more science-based, methodical practice of not only verifying a business's inventory but also maximising the amount of profit from the least amount of inventory investment without affecting customer satisfaction. Other facets of inventory control include forecasting future demand, supply chain management, production control, financial flexibility, purchasing data, loss prevention and turnover, and customer satisfaction.

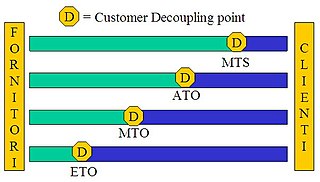

The business terms push and pull originated in logistics and supply chain management, but are also widely used in marketing and in the hotel distribution business.

The term demand chain has been used in a business and management context as contrasting terminology alongside, or in place of, "supply chain". Madhani suggests that the demand chain "comprises all the demand processes necessary to understand, create, and stimulate customer demand". Cranfield School of Management academic Martin Christopher has suggested that "ideally the supply chain should become a demand chain", explaining that ideally all product logistics and processing should occur "in response to a known customer requirement".

The bullwhip effect is a supply chain phenomenon where orders to suppliers tend to have a larger variability than sales to buyers, which results in an amplified demand variability upstream. In part, this results in increasing swings in inventory in response to shifts in consumer demand as one moves further up the supply chain. The concept first appeared in Jay Forrester's Industrial Dynamics (1961) and thus it is also known as the Forrester effect. It has been described as "the observed propensity for material orders to be more variable than demand signals and for this variability to increase the further upstream a company is in a supply chain". Research at Stanford University helped incorporate the concept into supply chain vernacular using a story about Volvo. Suffering a glut in green cars, sales and marketing developed a program to sell the excess inventory. While successful in generating the desired market pull, manufacturing did not know about the promotional plans. Instead, they read the increase in sales as an indication of growing demand for green cars and ramped up production.

Demand-chain management (DCM) is the management of relationships between suppliers and customers to deliver the best value to the customer at the least cost to the demand chain as a whole. Demand-chain management is similar to supply-chain management but with special regard to the customers.

Supply-chain optimization (SCO) aims to ensure the optimal operation of a manufacturing and distribution supply chain. This includes the optimal placement of inventory within the supply chain, minimizing operating costs including manufacturing costs, transportation costs, and distribution costs. Optimization often involves the application of mathematical modelling techniques using computer software. It is often considered to be part of supply chain engineering, although the latter is mainly focused on mathematical modelling approaches, whereas supply chain optimization can also be undertaken using qualitative, management based approaches.

Order fulfillment is in the most general sense the complete process from point of sales inquiry to delivery of a product to the customer. Sometimes, it describes the more narrow act of distribution or the logistics function. In the broader sense, it refers to the way firms respond to customer orders.

Value-stream mapping, also known as material- and information-flow mapping, is a lean-management method for analyzing the current state and designing a future state for the series of events that take a product or service from the beginning of the specific process until it reaches the customer. A value stream map is a visual tool that displays all critical steps in a specific process and easily quantifies the time and volume taken at each stage. Value stream maps show the flow of both materials and information as they progress through the process.

Production leveling, also known as production smoothing or – by its Japanese original term – heijunka (平準化), is a technique for reducing the mura (unevenness) which in turn reduces muda (waste). It was vital to the development of production efficiency in the Toyota Production System and lean manufacturing. The goal is to produce intermediate goods at a constant rate so that further processing may also be carried out at a constant and predictable rate.

A supply chain responsiveness matrix is a tool that is used to analyze inventory and lead time within an organization. The matrix is one of a number of value stream mapping tools. The matrix is represented by showing lead time along the x-axis and inventory along the y-axis. The result shows where slow moving stock resides.

Demand forecasting refers to the process of predicting the quantity of goods and services that will be demanded by consumers at a future point in time. More specifically, the methods of demand forecasting entail using predictive analytics to estimate customer demand in consideration of key economic conditions. This is an important tool in optimizing business profitability through efficient supply chain management. Demand forecasting methods are divided into two major categories, qualitative and quantitative methods. Qualitative methods are based on expert opinion and information gathered from the field. This method is mostly used in situations when there is minimal data available for analysis such as when a business or product has recently been introduced to the market. Quantitative methods, however, use available data, and analytical tools in order to produce predictions. Demand forecasting may be used in resource allocation, inventory management, assessing future capacity requirements, or making decisions on whether to enter a new market.

Trade promotion forecasting (TPF) is the process that attempts to discover multiple correlations between trade promotion characteristics and historic demand in order to provide accurate demand forecasting for future campaigns. The ability to distinguish the uplift or demand due to the impact of the trade promotion as opposed to baseline demand is fundamental to model promotion behavior. Model determination enables what-if analysis to evaluate different campaign scenarios with the goal of improving promotion effectiveness and ROI at the product-channel level by selecting the best scenario.

Operations management for services has the functional responsibility for producing the services of an organization and providing them directly to its customers. It specifically deals with decisions required by operations managers for simultaneous production and consumption of an intangible product. These decisions concern the process, people, information and the system that produces and delivers the service. It differs from operations management in general, since the processes of service organizations differ from those of manufacturing organizations.

References

- ↑ Best Practice Procurement: Public and Private Sector Perspectives By Andrew Erridge, Ruth Fee, John McIllroy

- ↑ Lean Evolution: Lessons from the Workplace By Nick Rich, Ann Esain, Nicola Bateman

- ↑ Demand Amplification within the supply chain