Washington Parish is a parish located in the interior southeast corner of the U.S. state of Louisiana, one of the Florida Parishes. As of the 2020 census, the population was 45,463. Its parish seat is Franklinton. Its largest city is Bogalusa. The parish was founded in 1819.

Bogalusa is a city in Washington Parish, Louisiana, United States. The population was 12,232 at the 2010 census. In the 2020 census the city reported a population of 10,659. It is the principal city of the Bogalusa Micropolitan Statistical Area, which includes all of Washington Parish and is also part of the larger New Orleans–Metairie–Hammond combined statistical area.

In organic chemistry, the Swern oxidation, named after Daniel Swern, is a chemical reaction whereby a primary or secondary alcohol is oxidized to an aldehyde or ketone using oxalyl chloride, dimethyl sulfoxide (DMSO) and an organic base, such as triethylamine. It is one of the many oxidation reactions commonly referred to as 'activated DMSO' oxidations. The reaction is known for its mild character and wide tolerance of functional groups.

Pulp is a fibrous lignocellulosic material prepared by chemically, semi-chemically or mechanically producing cellulosic fibers from wood, fiber crops, waste paper, or rags. Mixed with water and other chemicals or plant-based additives, pulp is the major raw material used in papermaking and the industrial production of other paper products.

Methanethiol is an organosulfur compound with the chemical formula CH

3SH. It is a colorless gas with a distinctive putrid smell. It is a natural substance found in the blood, brain and feces of animals, as well as in plant tissues. It also occurs naturally in certain foods, such as some nuts and cheese. It is one of the chemical compounds responsible for bad breath and the smell of flatus. Methanethiol is the simplest thiol and is sometimes abbreviated as MeSH. It is very flammable.

Georgia-Pacific LLC is an American pulp and paper company based in Atlanta, Georgia, and is one of the world's largest manufacturers and distributors of tissue, pulp, paper, toilet and paper towel dispensers, packaging, building products and related chemicals, and other forest products—largely made from its own timber. Since 2005, it has been an independently operated and managed subsidiary of Koch Industries. As of fall 2019, the company employed more than 35,000 people at more than 180 locations in North America, South America and Europe.

Temple-Inland, Inc. was an American corrugated packaging and building products company. It was acquired by International Paper in 2012.

Dimethyl sulfoxide (DMSO) is an organosulfur compound with the formula (CH3)2SO. This colorless liquid is the sulfoxide most widely used commercially. It is an important polar aprotic solvent that dissolves both polar and nonpolar compounds and is miscible in a wide range of organic solvents as well as water. It has a relatively high boiling point. DMSO is metabolised to compounds that leave a garlic-like taste in the mouth after DMSO is absorbed by skin.

The kraft process (also known as kraft pulping or sulfate process) is a process for conversion of wood into wood pulp, which consists of almost pure cellulose fibres, the main component of paper. The kraft process involves treatment of wood chips with a hot mixture of water, sodium hydroxide (NaOH), and sodium sulfide (Na2S), known as white liquor, that breaks the bonds that link lignin, hemicellulose, and cellulose. The technology entails several steps, both mechanical and chemical. It is the dominant method for producing paper. In some situations, the process has been controversial because kraft plants can release odorous products and in some situations produce substantial liquid wastes.

Dimethylsulfoniopropionate (DMSP), is an organosulfur compound with the formula (CH3)2S+CH2CH2COO−. This zwitterionic metabolite can be found in marine phytoplankton, seaweeds, and some species of terrestrial and aquatic vascular plants. It functions as an osmolyte as well as several other physiological and environmental roles have also been identified. DMSP was first identified in the marine red alga Polysiphonia fastigiata.

Dimethyl sulfide (DMS) or methylthiomethane is an organosulfur compound with the formula (CH3)2S. It is the simplest thioether and has a characteristic disagreeable odor. It is a flammable liquid that boils at 37 °C (99 °F). It is a component of the smell produced from cooking of certain vegetables, notably maize, cabbage, beetroot, and seafoods. It is also an indication of bacterial contamination in malt production and brewing. It is a breakdown product of dimethylsulfoniopropionate (DMSP), and is also produced by the bacterial metabolism of methanethiol.

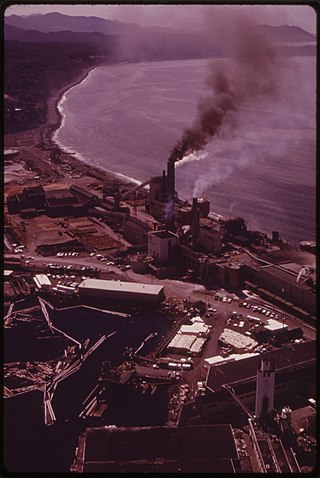

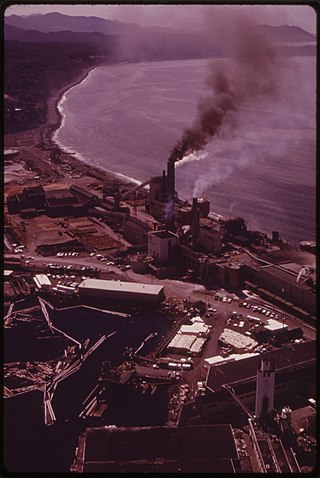

A pulp mill is a manufacturing facility that converts wood chips or other plant fiber sources into a thick fiber board which can be shipped to a paper mill for further processing. Pulp can be manufactured using mechanical, semi-chemical, or fully chemical methods. The finished product may be either bleached or non-bleached, depending on the customer requirements.

Gas to liquids (GTL) is a refinery process to convert natural gas or other gaseous hydrocarbons into longer-chain hydrocarbons, such as gasoline or diesel fuel. Methane-rich gases are converted into liquid synthetic fuels. Two general strategies exist: (i) direct partial combustion of methane to methanol and (ii) Fischer–Tropsch-like processes that convert carbon monoxide and hydrogen into hydrocarbons. Strategy ii is followed by diverse methods to convert the hydrogen-carbon monoxide mixtures to liquids. Direct partial combustion has been demonstrated in nature but not replicated commercially. Technologies reliant on partial combustion have been commercialized mainly in regions where natural gas is inexpensive.

In industrial chemistry, black liquor is the by-product from the kraft process when digesting pulpwood into paper pulp removing lignin, hemicelluloses and other extractives from the wood to free the cellulose fibers.

Lignosulfonates (LS) are water-soluble anionic polyelectrolyte polymers: they are byproducts from the production of wood pulp using sulfite pulping. Most delignification in sulfite pulping involves acidic cleavage of ether bonds, which connect many of the constituents of lignin. Sulfonated lignin (SL) refers to other forms of lignin by-product, such as those derived from the much more popular Kraft process, that have been processed to add sulfonic acid groups. The two have similar uses and are commonly confused with each other, with SL being much cheaper. LS and SL both appear as free-flowing powders; the former is light brown while the latter is dark brown.

Second-generation biofuels, also known as advanced biofuels, are fuels that can be manufactured from various types of non-food biomass. Biomass in this context means plant materials and animal waste used especially as a source of fuel.

The Great Southern Lumber Company was chartered in 1902 to harvest and market the virgin longleaf pine forests in southeastern Louisiana and southwestern Mississippi. Bogalusa, Louisiana was developed from the ground up as a company town and was the location for Great Southern Lumber Company's sawmill, which began operation in 1908. Other company interests included a railroad and paper mill. The company ceased operation in 1938, when the supply of virgin pines was depleted. Bogalusa became the site of a paper mill and chemical operations, followed by other industry.

Gaylord Container Corporation was an American integrated manufacturer of packaging materials, primarily corrugated containers. Operating from 1986 until 2002, most of the company's facilities were originally part of Crown Zellerbach's container division. Based in Deerfield, Illinois, a suburb north of Chicago, Gaylord Container completed its initial public offering in July 1988 and was listed on the American Stock Exchange. After less than 16 years as a company, it was acquired by a competitor, Temple-Inland, in early 2002, which was acquired by International Paper a decade later in 2012.

Crown Zellerbach was an American pulp and paper conglomerate based in San Francisco, California, purchased in a hostile takeover in 1985. Most of its pulp and paper assets were sold to James River Corporation, now part of Georgia-Pacific.

In industrial paper-making processes, organosolv is a pulping technique that uses an organic solvent to solubilise lignin and hemicellulose. It has been considered in the context of both pulp and paper manufacture and biorefining for subsequent conversion of cellulose to fuel ethanol. The process was invented by Theodor Kleinert in 1968 as an environmentally benign alternative to kraft pulping.