Glaze defects are any flaws in the surface quality of a ceramic glaze, its physical structure or its interaction with the body.

Glaze defects are any flaws in the surface quality of a ceramic glaze, its physical structure or its interaction with the body.

Certain glaze defects are a result of differences in the thermal expansion coefficient of the glaze and the clay body.

Crazing is a spider web pattern of cracks penetrating the glaze. It is caused by tensile stresses greater than the glaze is able to withstand. [1] [2] Common reasons for such stresses are: a mismatch between the thermal expansions of glaze and body; from moisture expansion of the body; and in the case of glazed tiles fixed to a wall, movement of the wall or of the bonding material used to fix the tile to the wall. [3] The cracks can allow the ingress of water into the cracks. Once fired, ware tends to be more resistant to crazing due to better development of the glaze/body interfacial layer, which reduces stress gradients between the glaze and body. [3]

In pottery a distinction is often made between crazing, as an accidental defect, and "crackle", which is when the same phenomenon, often strongly accentuated, is produced deliberately. The Chinese in particular enjoyed the random effects of crackle, though it spans a spectrum: in Ru ware it is a tolerated feature of most pieces, but not sought, while in Guan ware a strong crackle is a desired effect.

The causes of crazing include: [1] [3]

Steger's Crazing Test is a method for the assessment of the glaze fit. It is undertaken by measuring any deformation on cooling of a thin bar that was glazed only on one side. [4] [5] [6] A common method of testing glazed ceramic ware for crazing resistance is to expose pieces of ware to the steam in an autoclave at a minimum of 50 psi. [7] [8]

Seger's Rules are a series of empirical rules put forward by Hermann Seger for the prevention of crazing and peeling. To prevent crazing, the body should be adjusted as follows: decrease the clay, increase the free silica; replace some of the ball clay by kaolin; decrease the feldspar; grind the silica more finely; biscuit fire at higher temperature. Alternatively, the glaze can be adjusted: increase silica and/or decrease fluxes; replace some SiO2 by B2O3; replace fluxes of high equivalent weight by fluxes of lower equivalent weight. To prevent peeling, the body or glaze should be adjusted in the reverse direction. [9]

Shivering describes the breaking away of glaze from ceramic ware as a result of greater compression in the glaze layer than the body caused by the glaze having an expansion coefficient below the clay body's. [10]

It is the opposite of crazing, as are the preventative steps: see Seger's Rule above. Shivering is also known as peeling. [3] [11] [12]

Regulations have existed since the late 1960s to protect consumers from the potential risk of toxic materials, mainly metals, being released from glazes into drink and foodstuffs. Lead and cadmium are the metals of greatest concern, although testing can be extended to include others. The propensity for any glaze to release metal may depend on complex interactions between the formulation used, any applied decoration and the kiln atmosphere. [1]

Monitoring the level of metal release from glazed ware forms part of the quality control procedures of all reputable producers. [1] [13] Test methods are specified according to national and international standards, although testing usually involves: the ware being immersed or filled with a 4% acetic acid solution; covered and left for 24 hours at room temperature, although if cooking ware is being tested higher temperatures are needed; the acetic acid solution decanted from the ware and the concentration of leached metal measured by Atomic absorption spectroscopy. [14] Acceptance limits are enforced by legislation, and whilst varying between countries all are within the ppm range. Some of the most well recognised legislation are: across Europe 'EC Directive 84/500/EEC 1984'; for the UK 'GB Ceramic Ware (Safety) Regulations SI 1647, 1988'; and for the USA 'FDA Compliance Policy Guide 7117.06 and 7117.07 for cadmium and lead.' [15] [16] [17]

A large bubble sometimes present as a fault in ceramic ware. Blisters appear as large bubbles either just below or penetrating the surface, leaving sharp, rough edges that collect dirt. The surface of the glaze is very unpleasant and looks like a boiled mass of bubbles, craters and pinholes. [3] [18]

A defect that appears as irregular, bare patches of fired body showing through the glaze where it has failed to adhere to or wet the body on firing. The cause is a weak bond between glaze and body; this may result from greasy patches or dust on the surface of the biscuit ware or from shrinkage of the applied glaze slip during drying. The fault is more likely to occur with once-fired ware such as sanitaryware. [1] [3] [19] [20]

Metal marks are dark lines, often accompanied by damage in the glaze, caused by the deposition of metal during the use of metal utensils. The cutlery, or other relatively soft metal, will leave a very thin smear of metal on pottery ware if the glaze is minutely pitted. A glaze may have this defective surface as it leaves the glost kiln, or it may subsequently develop such a surface as a result of inadequate chemical durability. The fault is also known as cutlery marking. [3] [21] [22] [23]

A fault that is commonly the result of a bubble in the glaze when it was molten that burst but was only partially healed. The bubbles are most often from gas that originates from air trapped between the particles of powdered glaze as the glaze begins to mature, or from gases evolved from carbonate compounds. [24] [25]

A specific example of pin-holes is Spit-out. These are pin-holes or craters sometimes occurring in glazed non-vitreous ceramics while they are in the decorating kiln. The cause of this defect is the evolution of water vapour, adsorbed by the porous body, during the period between the glost firing and the decorating firing, via minute cracks in the glaze. [26] [27]

A ceramic is any of the various hard, brittle, heat-resistant, and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcelain, and brick.

Pottery is the process and the products of forming vessels and other objects with clay and other raw materials, which are fired at high temperatures to give them a hard and durable form. The place where such wares are made by a potter is also called a pottery. The definition of pottery, used by the ASTM International, is "all fired ceramic wares that contain clay when formed, except technical, structural, and refractory products". End applications include tableware, decorative ware, sanitary ware, and in technology and industry such as electrical insulators and laboratory ware. In art history and archaeology, especially of ancient and prehistoric periods, pottery often means vessels only, and sculpted figurines of the same material are called terracottas.

Raku ware is a type of Japanese pottery traditionally used in Japanese tea ceremonies, most often in the form of chawan tea bowls. It is traditionally characterised by being hand-shaped rather than thrown, fairly porous vessels, which result from low firing temperatures, lead glazes and the removal of pieces from the kiln while still glowing hot. In the traditional Japanese process, the fired raku piece is removed from the hot kiln and is allowed to cool in the open air.

Porcelain is a ceramic material made by heating raw materials, generally including kaolinite, in a kiln to temperatures between 1,200 and 1,400 °C. The greater strength and translucence of porcelain, relative to other types of pottery, arise mainly from vitrification and the formation of the mineral mullite within the body at these high temperatures. End applications include tableware, decorative ware such as figurines, and products in technology and industry such as electrical insulators and laboratory ware.

Longquan celadon is a type of green-glazed Chinese ceramic, known in the West as celadon or greenware, produced from about 950 to 1550. The kilns were mostly in Lishui prefecture in southwestern Zhejiang Province in the south of China, and the north of Fujian Province. Overall a total of some 500 kilns have been discovered, making the Longquan celadon production area one of the largest historical ceramic producing areas in China. "Longquan-type" is increasingly preferred as a term, in recognition of this diversity, or simply "southern celadon", as there was also a large number of kilns in north China producing Yaozhou ware or other Northern Celadon wares. These are similar in many respects, but with significant differences to Longquan-type celadon, and their production rose and declined somewhat earlier.

Earthenware is glazed or unglazed nonvitreous pottery that has normally been fired below 1,200 °C (2,190 °F). Basic earthenware, often called terracotta, absorbs liquids such as water. However, earthenware can be made impervious to liquids by coating it with a ceramic glaze, and such a process is used for the great majority of modern domestic earthenware. The main other important types of pottery are porcelain, bone china, and stoneware, all fired at high enough temperatures to vitrify. End applications include tableware and decorative ware such as figurines.

Stoneware is a broad term for pottery fired at a relatively high temperature. A modern definition is a vitreous or semi-vitreous ceramic made primarily from stoneware clay or non-refractory fire clay. End applications include tableware, decorative ware such as vases.

Pyrometric cones are pyrometric devices that are used to gauge heatwork during the firing of ceramic materials in a kiln. The cones, often used in sets of three, are positioned in a kiln with the wares to be fired and, because the individual cones in a set soften and fall over at different temperatures, they provide a visual indication of when the wares have reached a required state of maturity, a combination of time and temperature.

A saggar is a type of kiln furniture. It is a ceramic boxlike container used in the firing of pottery to enclose or protect ware being fired inside a kiln. The name may be a contraction of the word safeguard.

Slip casting, or slipcasting, is a ceramic forming technique, and is widely used in industry and by craft potters to make ceramic forms. This technique typically used to form complicated shapes like figurative ceramics that would be difficult to be reproduced by hand or other forming techniques. The technique involves a clay body slip, usually prepared in a blunger, being poured into plaster moulds and allowed to form a layer, the cast, on the internal walls of the mould.

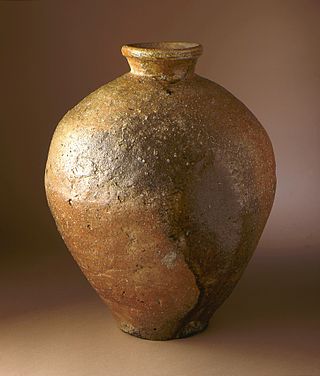

Shigaraki ware (信楽焼) is a type of stoneware pottery made in Shigaraki area, Japan. The kiln is one of the Six Ancient Kilns in Japan. Although figures representing the tanuki are a popular product included as Shigaraki ware, the kiln and local pottery tradition has a long history.

Chinese ceramics are one of the most significant forms of Chinese art and ceramics globally. They range from construction materials such as bricks and tiles, to hand-built pottery vessels fired in bonfires or kilns, to the sophisticated Chinese porcelain wares made for the imperial court and for export.

Tin-glazing is the process of giving tin-glazed pottery items a ceramic glaze that is white, glossy and opaque, which is normally applied to red or buff earthenware. Tin-glaze is plain lead glaze with a small amount of tin oxide added. The opacity and whiteness of tin glaze encourage its frequent decoration. Historically this has mostly been done before the single firing, when the colours blend into the glaze, but since the 17th century also using overglaze enamels, with a light second firing, allowing a wider range of colours. Majolica, maiolica, delftware and faience are among the terms used for common types of tin-glazed pottery.

Ceramic glaze, or simply glaze, is a glassy coating on ceramics. It is used for decoration, to ensure the item is impermeable to liquids and to minimise the adherence of pollutants.

This is a list of pottery and ceramic terms.

The room-temperature form of quartz, α-quartz, undergoes a reversible change in crystal structure at 573 °C to form β-quartz. This phenomenon is called an inversion, and for the α to β quartz inversion is accompanied by a linear expansion of 0.45%. This inversion can lead to cracking of ceramic ware if cooling occurs too quickly through the inversion temperature. This is called dunting, and the resultant faults as dunts. To avoid such thermal shock faults, cooling rates not exceeding 50 °C/hour have been recommended.

Biscuit refers to any pottery that has been fired in a kiln without a ceramic glaze. This can be a final product such as biscuit porcelain or unglazed earthenware or, most commonly, an intermediate stage in a glazed final product.

Dick Lehman is an American ceramics artist based in Indiana. Dozens of articles and photos featuring his techniques and insights have appeared in periodicals and books on ceramic art since 1985, including 34 articles in U.S.-published Ceramics Monthly, the largest circulating magazine in the field, plus articles in 11 other international periodicals.

Kiln furniture are devices and implements inside furnaces used during the heating of manufactured individual pieces, such as pottery or other ceramic or metal components. Kiln furniture is made of refractory materials, i.e., materials that withstand high temperatures without deformation. Kiln furniture can account for up to 80% of the mass of a kiln charge.

Hermann Seger (1832–1893) was a German ceramicist who is widely credited with pioneering the development of the pyrometric cone, which enabled the rapid growth of the ceramic industry around the turn of the century.