A ceramic is any of the various hard, brittle, heat-resistant, and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcelain, and brick.

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction. Sintering happens as part of a manufacturing process used with metals, ceramics, plastics, and other materials. The nanoparticles in the sintered material diffuse across the boundaries of the particles, fusing the particles together and creating a solid piece.

Powder metallurgy (PM) is a term covering a wide range of ways in which materials or components are made from metal powders. PM processes can reduce or eliminate the need for subtractive processes in manufacturing, lowering material losses and reducing the cost of the final product.

Bone ash is a white material produced by the calcination of bones. Typical bone ash consists of about 55.82% calcium oxide, 42.39% phosphorus pentoxide, and 1.79% water. The exact composition of these compounds varies depending upon the type of bones being used, but generally the formula for bone ash is Ca5(OH)(PO4)3. Bone ash usually has a density around 3.10 g/mL and a melting point of 1670 °C (3038 °F). Most bones retain their cellular structure through calcination.

Selective laser sintering (SLS) is an additive manufacturing (AM) technique that uses a laser as the power and heat source to sinter powdered material, aiming the laser automatically at points in space defined by a 3D model, binding the material together to create a solid structure. It is similar to selective laser melting; the two are instantiations of the same concept but differ in technical details. SLS is a relatively new technology that so far has mainly been used for rapid prototyping and for low-volume production of component parts. Production roles are expanding as the commercialization of AM technology improves.

Many ceramic materials, both glassy and crystalline, have found use as optically transparent materials in various forms from bulk solid-state components to high surface area forms such as thin films, coatings, and fibers. Such devices have found widespread use for various applications in the electro-optical field including: optical fibers for guided lightwave transmission, optical switches, laser amplifiers and lenses, hosts for solid-state lasers and optical window materials for gas lasers, and infrared (IR) heat seeking devices for missile guidance systems and IR night vision.

Hot isostatic pressing (HIP) is a manufacturing process, used to reduce the porosity of metals and increase the density of many ceramic materials. This improves the material's mechanical properties and workability.

In materials science, the sol–gel process is a method for producing solid materials from small molecules. The method is used for the fabrication of metal oxides, especially the oxides of silicon (Si) and titanium (Ti). The process involves conversion of monomers into a colloidal solution (sol) that acts as the precursor for an integrated network of either discrete particles or network polymers. Typical precursors are metal alkoxides. Sol-gel process is used to produce ceramic nanoparticles.

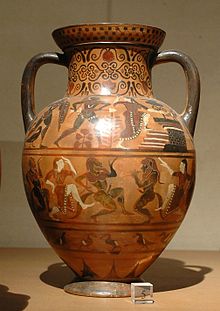

Ceramic forming techniques are ways of forming ceramics, which are used to make everything from tableware such as teapots to engineering ceramics such as computer parts. Pottery techniques include the potter's wheel, slip casting and many others.

Silicon nitride is a chemical compound of the elements silicon and nitrogen. Si

3N

4 is the most thermodynamically stable and commercially important of the silicon nitrides, and the term ″Silicon nitride″ commonly refers to this specific composition. It is a white, high-melting-point solid that is relatively chemically inert, being attacked by dilute HF and hot H

3PO

4. It is very hard. It has a high thermal stability with strong optical nonlinearities for all-optical applications.

Ceramic engineering is the science and technology of creating objects from inorganic, non-metallic materials. This is done either by the action of heat, or at lower temperatures using precipitation reactions from high-purity chemical solutions. The term includes the purification of raw materials, the study and production of the chemical compounds concerned, their formation into components and the study of their structure, composition and properties.

Egyptian faience is a sintered-quartz ceramic material from Ancient Egypt. The sintering process "covered [the material] with a true vitreous coating" as the quartz underwent vitrification, creating a bright lustre of various colours "usually in a transparent blue or green isotropic glass". Its name in the Ancient Egyptian language was tjehenet, and modern archeological terms for it include sintered quartz, glazed frit, and glazed composition. Tjehenet is distinct from the crystalline pigment Egyptian blue, for which it has sometimes incorrectly been used as a synonym.

A frit is a ceramic composition that has been fused, quenched, and granulated. Frits form an important part of the batches used in compounding enamels and ceramic glazes; the purpose of this pre-fusion is to render any soluble and/or toxic components insoluble by causing them to combine with silica and other added oxides. However, not all glass that is fused and quenched in water is frit, as this method of cooling down very hot glass is also widely used in glass manufacture.

Lithium titanates are chemical compounds of lithium, titanium and oxygen. They are mixed oxides and belong to the titanates. The most important lithium titanates are:

Selective laser melting (SLM) is one of many proprietary names for a metal additive manufacturing (AM) technology that uses a bed of powder with a source of heat to create metal parts. Also known as direct metal laser sintering (DMLS), the ASTM standard term is powder bed fusion (PBF). PBF is a rapid prototyping, 3D printing, or additive manufacturing technique designed to use a high power-density laser to melt and fuse metallic powders together.

Binder jet 3D printing, known variously as "Powder bed and inkjet" and "drop-on-powder" printing, is a rapid prototyping and additive manufacturing technology for making objects described by digital data such as a CAD file. Binder jetting is one of the seven categories of additive manufacturing processes according to ASTM and ISO.

Ceramic nanoparticle is a type of nanoparticle that is composed of ceramics, which are generally classified as inorganic, heat-resistant, nonmetallic solids that can be made of both metallic and nonmetallic compounds. The material offers unique properties. Macroscale ceramics are brittle and rigid and break upon impact. However, Ceramic nanoparticles take on a larger variety of functions, including dielectric, ferroelectric, piezoelectric, pyroelectric, ferromagnetic, magnetoresistive, superconductive and electro-optical.

Compaction of ceramic powders is a forming technique for ceramics in which granular ceramic materials are made cohesive through mechanical densification, either by hot or cold pressing. The resulting green part must later be sintered in a kiln. The compaction process permits an efficient production of parts to close tolerances with low drying shrinkage. It can be used for parts ranging widely in size and shape, and for both technical and nontechnical ceramics.

Ultra-high-temperature ceramics (UHTCs) are a type of refractory ceramics that that can withstand extremely high temperatures without degrading, often above 2,000 °C. They also often have high thermal conductivities and are highly resistant to thermal shock, meaning they can withstand sudden and extreme changes in temperature without cracking or breaking. Chemically, they are usually borides, carbides, nitrides, and oxides of early transition metals.

A variety of processes, equipment, and materials are used in the production of a three-dimensional object via additive manufacturing. 3D printing is also known as additive manufacturing, because the numerous available 3D printing process tend to be additive in nature, with a few key differences in the technologies and the materials used in this process.