A high gloss surface with haze exhibits a milky finish with low reflective contrast- reflected highlights and lowlights are less pronounced. On surfaces with haze, halos are visible around the reflections of strong light sources.

Measurement

Measurement of reflection haze is primarily defined under three International test standards:

ASTM E430

ASTM E430 comprises three test methods: [1]

Test method A specifies a 30° angle for specular gloss measurement, 28° or 32° for narrow-angle reflection haze measurement and 25° or 35° for wide-angle reflection haze measurement.

Test method B specifies a 20° angle for specular gloss measurement and 18.1° and 21.9° for narrow-angle reflection haze measurement.

Test method C specifies a 30° angle for specular gloss measurement, 28° or 32° for narrow-angle reflection haze measurement and 15° wide-angle reflection haze measurement.

ASTM D4039

Test method specifies gloss measurements to be made at 20° and 60°, the haze index is then calculated as the difference between the 60° and 20° measurements. [2]

ISO 13803

Source: [3]

Test method specifies a 20° angle for specular gloss measurement and 18.1° and 21.9° for narrow-angle reflection haze measurement.

All test methods specify that measurements should be made with visible light according to CIE spectral luminous efficiency function V(λ) in the CIE 1931 standard observer and CIE standard illuminant C.

As most commercially available glossmeters have gloss measurement angles of 20°, 60° and 85° haze measurement is incorporated at either 20° (ISO 13803 / ASTM E430 method B) or at 20° and 60° ( ASTM D4039). There are however some manufacturers that offer glossmeters with measurement angles of 30° and haze measurement in accordance with ASTM E430 Method A and C but are fewer in number, therefore for the purposes of detailing haze measurement theory only the first three methods will be included.

ISO 13803 / ASTM E430 method B

Both test methods measure specular gloss and haze together at 20° that means light is transmitted and received at an equal but opposite angle of 20°.

Specular gloss is measured over an angular range that is limited by aperture dimensions as defined in ASTM Test Method D523. The angular measurement range for this at 20° is ±0.9° (19.1° - 20.9°). For haze measurement additional sensors are used either side of this range at 18.1° and 21.9° to measure the intensity of the scattered light. Both solid colours and those containing metallics can be measured using this method provided haze compensation is used (as detailed later).

ASTM D4039

This method can only be used on nonmetallic materials having a 60° specular gloss value greater than 70 in accordance with ASTM Test Method D523 / ISO 2813. Haze Index is calculated from gloss measurements made at 20 and 60 degrees as the difference between the two measurements (HI = G60-G20).

As measurements of specular gloss depend largely on the refractive index of the material being measured 20° gloss will change more noticeably than 60° gloss, therefore as haze index is calculated using these two measurements it too will be affected by the refractive index of the material. Evaluations of reflection haze using this test method are therefore confined to samples of roughly the same refractive index.

Haze compensation

It is important to note that the colour (luminous reflectance) of a material can greatly influence the measurement of reflection haze. As colour and haze are both components of scattered light (diffuse reflectance) they must be separated so that only the haze value is quantified; this is also true for metallics or coatings containing metallic pigments where a higher scattering exists.

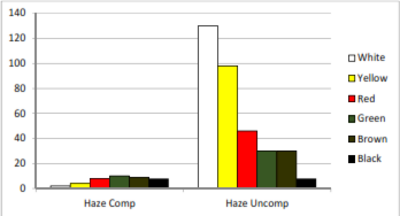

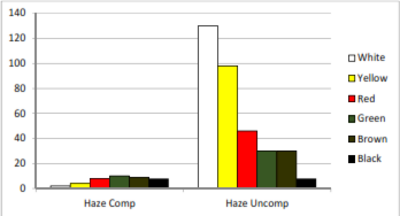

As test method ASTM D4039 is only suitable for nonmetallic materials of more or less the same refractive index separation of the colour and haze components is not detailed. Haze index calculations and measurements using this test method will therefore produce higher haze results on brighter coloured materials than darker with the same level of haze present. The chart below shows these differences for various colours:-

Both ISO 13803 and ASTM E430 method B require a separate measurement of luminous reflectance, Y, to calculate compensated haze. The tri-stimulus value Y gives a measure of the lightness of the material as defined in ISO 7724-2 requiring a 45°/0° geometry to be used with standard illuminant C and 2° observer (although it is mentioned that slightly different conditions will not result in significant errors). Luminous reflectance measurements, Y, are required on both the sample material and a reference white; ISO 13803 details the use of a BaSO4 standard - barium sulphate, a white crystalline solid having a white opaque appearance and high density as this material is a good substitute for a perfectly reflecting diffusor as defined under ISO 7724-2.

Compensated haze can then be calculated as -

H Comp = H Linear – Y Sample / Y BaSO4

Using the ISO / ASTM method therefore to measure luminous reflectance produces a reliable measurement of Y for non-metallic surfaces as the diffuse component is lambertian, i.e. it is equal in amplitude at all angles in relation to the sample surface.

However, for metallic coatings and those containing speciality pigments, as the particles within the coating reflect the light directionally around the specular angle, little or no metallic reflection is present at the angle at which the luminosity is measured, therefore these types of coatings have an unexpectedly high haze reading. Using a measurement angle which is closer to the region adjacent to the haze angle has proven successful in providing compatible readings on solid colours and also compensating for directional reflection from metallic coatings and speciality pigments