Stairs are a structure designed to bridge a large vertical distance between lower and higher levels by dividing it into smaller vertical distances. This is achieved as a diagonal series of horizontal platforms called steps which enable passage to the other level by stepping from one to another step in turn. Steps are very typically rectangular. Stairs may be straight, round, or may consist of two or more straight pieces connected at angles.

In machining, a shaper is a type of machine tool that uses linear relative motion between the workpiece and a single-point cutting tool to machine a linear toolpath. Its cut is analogous to that of a lathe, except that it is (archetypally) linear instead of helical.

A yoke, alternatively known as a control wheel or a control column, is a device used for piloting some fixed-wing aircraft.

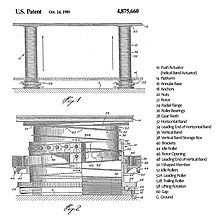

A linear actuator is an actuator that creates motion in a straight line, in contrast to the circular motion of a conventional electric motor. Linear actuators are used in machine tools and industrial machinery, in computer peripherals such as disk drives and printers, in valves and dampers, and in many other places where linear motion is required. Hydraulic or pneumatic cylinders inherently produce linear motion. Many other mechanisms are used to generate linear motion from a rotating motor.

A jackscrew, or screw jack, is a type of jack that is operated by turning a leadscrew. It is commonly used to lift moderately and heavy weights, such as vehicles; to raise and lower the horizontal stabilizers of aircraft; and as adjustable supports for heavy loads, such as the foundations of houses.

A fly system, or theatrical rigging system, is a system of ropes, blocks (pulleys), counterweights and related devices within a theater that enables a stage crew to fly (hoist) quickly, quietly and safely components such as curtains, lights, scenery, stage effects and, sometimes, people. Systems are typically designed to fly components between clear view of the audience and out of view, into the large space, the fly loft, above the stage.

A hydraulic cylinder is a mechanical actuator that is used to give a unidirectional force through a unidirectional stroke. It has many applications, notably in construction equipment, manufacturing machinery, elevators, and civil engineering. A hydraulic cylinder is a hydraulic actuator that provides linear motion when hydraulic energy is converted into mechanical movement. It can be likened to a muscle in that, when the hydraulic system of a machine is activated, the cylinder is responsible for providing the motion.

Pneumatic cylinder, also known as air cylinder, is a mechanical device which uses the power of compressed gas to produce a force in a reciprocating linear motion.

A jack is a mechanical lifting device used to apply great forces or lift heavy loads. A mechanical jack employs a screw thread for lifting heavy equipment. A hydraulic jack uses hydraulic power. The most common form is a car jack, floor jack or garage jack, which lifts vehicles so that maintenance can be performed. Jacks are usually rated for a maximum lifting capacity. Industrial jacks can be rated for many tons of load.

Mechanical railway signalling installations rely on lever frames for their operation to interlock the signals, track locks and points to allow the safe operation of trains in the area the signals control. Usually located in the signal box, the levers are operated either by the signalman or the pointsman.

Artificial lift refers to the use of artificial means to increase the flow of liquids, such as crude oil or water, from a production well. Generally this is achieved by the use of a mechanical device inside the well or by decreasing the weight of the hydrostatic column by injecting gas into the liquid some distance down the well. A newer method called Continuous Belt Transportation (CBT) uses an oil absorbing belt to extract from marginal and idle wells. Artificial lift is needed in wells when there is insufficient pressure in the reservoir to lift the produced fluids to the surface, but often used in naturally flowing wells to increase the flow rate above what would flow naturally. The produced fluid can be oil, water or a mix of oil and water, typically mixed with some amount of gas.

Well completion is the process of making a well ready for production after drilling operations. This principally involves preparing the bottom of the hole to the required specifications, running in the production tubing and its associated down hole tools as well as perforating and stimulating as required. Sometimes, the process of running in and cementing the casing is also included. After a well has been drilled, should the drilling fluids be removed, the well would eventually close in upon itself. Casing ensures that this will not happen while also protecting the wellstream from outside incumbents, like water or sand.

A segmented spindle, also known by the trademark Kataka, is a specialized mechanical linear actuator conceived by the Danish mechanical engineer Jens Joerren Soerensen during the mid-1990s. The actuator forms a telescoping tubular column, or spindle, from linked segments resembling curved parallelograms. The telescoping linear actuator has a lifting capacity up to 200 kg for a travel of 400 mm (~15.75 inches).

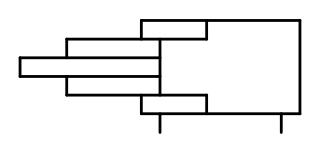

Telescopic cylinders are a special design of a hydraulic cylinder or pneumatic cylinder as well as pulley system which provide an exceptionally long output travel from a very compact retracted length. Typically the collapsed length of a telescopic cylinder is 20 to 40% of the fully extended length depending on the number of stages. Some pneumatic telescoping units are manufactured with retracted lengths of under 15% of overall extended unit length. This feature is very attractive to machine design engineers when a conventional single stage rod style actuator will not fit in an application to produce the required output stroke.

A rigid chain actuator, known variously as a linear chain actuator, push-pull chain actuator, electric chain actuator or column-forming chain actuator, is a specialized mechanical linear actuator used in window operating, push-pull material handling and lift applications. The actuator is a chain and pinion device that forms an articulated telescoping member to transmit traction and thrust. High-capacity rigid chain lifting columns (jacks) can move dynamic loads exceeding 10 tonnes (22,000 lb) over more than 7 metres (23 ft) of travel.

A rigid belt actuator, also known as a push-pull belt actuator or zipper belt actuator, is a specialized mechanical linear actuator used in push-pull and lift applications. The actuator is a belt and pinion device that forms a telescoping beam or column member to transmit traction and thrust. Rigid belt actuators can move dynamic loads up to approximately 230 pounds over about 3 feet of travel.

A pipe support or pipe hanger is a designed element that transfer the load from a pipe to the supporting structures. The load includes the weight of the pipe proper, the content that the pipe carries, all the pipe fittings attached to pipe, and the pipe covering such as insulation. The four main functions of a pipe support are to anchor, guide, absorb shock, and support a specified load. Pipe supports used in high or low temperature applications may contain insulation materials. The overall design configuration of a pipe support assembly is dependent on the loading and operating conditions.

A scissors mechanism uses linked, folding supports in a criss-cross 'X' pattern.

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying directions on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances.

This page is a glossary of Prestressed concrete terms.