Related Research Articles

Electrochemistry is the branch of physical chemistry concerned with the relationship between electrical potential, as a measurable and quantitative phenomenon, and identifiable chemical change, with either electrical potential as an outcome of a particular chemical change, or vice versa. These reactions involve electrons moving between electrodes via an electronically-conducting phase, separated by an ionically-conducting and electronically insulating electrolyte.

Iridium is a chemical element with the symbol Ir and atomic number 77. A very hard, brittle, silvery-white transition metal of the platinum group, iridium is considered to be the second-densest metal with a density of 22.56 g/cm3 as defined by experimental X-ray crystallography. However, at room temperature and standard atmospheric pressure, iridium has been calculated to have a density of 22.65 g/cm3, 0.04 g/cm3 higher than osmium measured the same way. Still, the experimental X-ray crystallography value is considered to be the most accurate, and as such iridium is considered to be the second densest element. It is the most corrosion-resistant metal, even at temperatures as high as 2000 °C. Although only certain molten salts and halogens are corrosive to solid iridium, finely divided iridium dust is much more reactive and can be flammable.

Ruthenium is a chemical element with the symbol Ru and atomic number 44. It is a rare transition metal belonging to the platinum group of the periodic table. Like the other metals of the platinum group, ruthenium is inert to most other chemicals. Russian-born scientist of Baltic-German ancestry Karl Ernst Claus discovered the element in 1844 at Kazan State University and named ruthenium in honor of Russia. Ruthenium is usually found as a minor component of platinum ores; the annual production has risen from about 19 tonnes in 2009 to some 35.5 tonnes in 2017. Most ruthenium produced is used in wear-resistant electrical contacts and thick-film resistors. A minor application for ruthenium is in platinum alloys and as a chemistry catalyst. A new application of ruthenium is as the capping layer for extreme ultraviolet photomasks. Ruthenium is generally found in ores with the other platinum group metals in the Ural Mountains and in North and South America. Small but commercially important quantities are also found in pentlandite extracted from Sudbury, Ontario and in pyroxenite deposits in South Africa.

In chemistry and manufacturing, electrolysis is a technique that uses direct electric current (DC) to drive an otherwise non-spontaneous chemical reaction. Electrolysis is commercially important as a stage in the separation of elements from naturally occurring sources such as ores using an electrolytic cell. The voltage that is needed for electrolysis to occur is called the decomposition potential. The word "lysis" means to separate or break, so in terms, electrolysis would mean either "breakdown of electricity" or "breakdown via electricity".

Electroplating is a general name for processes that create a metal coating on a solid substrate through the reduction of cations of that metal by means of a direct electric current. The part to be coated acts as the cathode of an electrolytic cell; the electrolyte is a solution of a salt of the metal to be coated; and the anode is usually either a block of that metal, or of some inert conductive material. The current is provided by an external power supply.

In chemistry, noble metals are metallic elements that show outstanding resistance to chemical attack even at high temperatures. They are well known for their catalytic properties and associated capacity to facilitate or control the rates of chemical reactions. The short list of chemically noble metals comprises ruthenium (Ru), rhodium (Rh), palladium (Pd), osmium (Os), iridium (Ir), platinum (Pt), gold (Au), silver (Ag). In periodic table terms, an analogy can be made between the noble metals and the noble gases, which are mainly unreactive.

The chloralkali process is an industrial process for the electrolysis of sodium chloride solutions. It is the technology used to produce chlorine and sodium hydroxide, which are commodity chemicals required by industry. 35 million tons of chlorine were prepared by this process in 1987. The chlorine and sodium hydroxide produced in this process are widely used in the chemical industry.

Lead(IV) oxide is the inorganic compound with the formula PbO2. It is an oxide where lead is in an oxidation state of +4. It is a dark-brown solid which is insoluble in water. It exists in two crystalline forms. It has several important applications in electrochemistry, in particular as the positive plate of lead acid batteries.

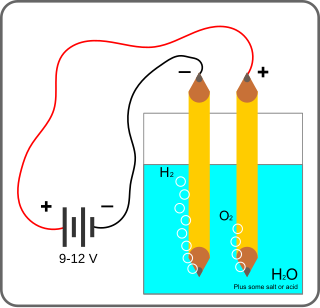

Electrolysis of water is the process of using electricity to decompose water into oxygen and hydrogen gas. Hydrogen gas released in this way can be used as hydrogen fuel, or remixed with the oxygen to create oxyhydrogen gas, which is used in welding and other applications.

In electrochemistry, overpotential is the potential difference (voltage) between a half-reaction's thermodynamically determined reduction potential and the potential at which the redox event is experimentally observed. The term is directly related to a cell's voltage efficiency. In an electrolytic cell the existence of overpotential implies the cell requires more energy than thermodynamically expected to drive a reaction. In a galvanic cell the existence of overpotential means less energy is recovered than thermodynamics predicts. In each case the extra/missing energy is lost as heat. The quantity of overpotential is specific to each cell design and varies across cells and operational conditions, even for the same reaction. Overpotential is experimentally determined by measuring the potential at which a given current density is achieved.

Ruthenium(IV) oxide is the inorganic compound with the formula RuO2. This black solid is the most common oxide of ruthenium. It is widely used as an electrocatalyst for producing chlorine, chlorine oxides, and O2 catalyst is ruthenium(IV) oxide. Like many dioxides, RuO2 adopts the rutile structure.

The Castner–Kellner process is a method of electrolysis on an aqueous alkali chloride solution to produce the corresponding alkali hydroxide, invented by American Hamilton Castner and Austrian Karl Kellner in the 1890s.

Platinum black is a fine powder of platinum with good catalytic properties. The name of platinum black is due to its black color. It is used in many ways; as a thin film electrode, a fuel cell membrane catalyst, or as a catalytic ignition of flammable gases for "self-lighting' gas lamps, ovens, and stove burners.

Mixed metal oxide (MMO) electrodes, also called Dimensionally Stable Anodes (DSA), are devices with high conductivity and corrosion resistance for use as anodes in electrolysis. They are made by coating a substrate, such as pure titanium plate or expanded mesh, with several kinds of metal oxides. One oxide is usually RuO2, IrO2, or PtO2, which conducts electricity and catalyzes the desired reaction such as the production of chlorine gas. The other metal oxide is typically titanium dioxide which does not conduct or catalyze the reaction, but is cheaper and prevents corrosion of the interior.

Iridium(IV) oxide, IrO2, is the only well characterised oxide of iridium. It is a blue black solid. The compound adopts the TiO2, rutile structure, featuring six coordinate iridium and three coordinate oxygen.

A membrane electrode assembly (MEA) is an assembled stack of proton-exchange membranes (PEM) or alkali anion exchange membrane (AAEM), catalyst and flat plate electrode used in fuel cells and electrolyzers.

Chlorine gas can be produced by extracting from natural materials, including the electrolysis of a sodium chloride solution (brine) and other ways.

A metal–air electrochemical cell is an electrochemical cell that uses an anode made from pure metal and an external cathode of ambient air, typically with an aqueous or aprotic electrolyte. During discharging of a metal–air electrochemical cell, a reduction reaction occurs in the ambient air cathode while the metal anode is oxidized. The specific capacity and energy density of metal–air electrochemical cells is higher than that of lithium-ion batteries, making them a prime candidate for use in electric vehicles. However, complications associated with the metal anodes, catalysts, and electrolytes have hindered development and implementation of metal–air batteries, though there are some commercial applications.

Water oxidation is one of the half reactions of water splitting:

Electro-oxidation(EO), also known as anodic oxidation or electrochemical oxidation, is a technique used for wastewater treatment, mainly for industrial effluents, and is a type of advanced oxidation process (AOP). The most general layout comprises two electrodes, operating as anode and cathode, connected to a power source. When an energy input and sufficient supporting electrolyte are provided to the system, strong oxidizing species are formed, which interact with the contaminants and degrade them. The refractory compounds are thus converted into reaction intermediates and, ultimately, into water and CO2 by complete mineralization.

References

- ↑ H.B. Beer. Journal of Electrochemical Soc. 127, 1980, 303C

- ↑ "Tue Honorary doctorates". www.tue.nl. Archived from the original on 2018-07-20. Retrieved 2018-05-29.

- ↑ "News".

- ↑ "Magneto Special Anodes".

- ↑ P.C.S. Hayfield, Plat. Met. Rev. 42, 1998, 46

- ↑ P.C.S. Hayfield, Plat. Met. Rev. 42, 1998, 27

- ↑ GB 1147442,Beer, Henri Bernard,"Improvements in or relating to electrodes for electrolysis",published 1969-04-02

- ↑ GB 1195871,Beer, Henri Bernard,"Improvements in or relating to the Manufacture of Electrodes.",published 1970-06-24

- ↑ H.B. Beer. Journal of Electrochemical Soc. 127, 1980, 303C

- ↑ P.C.S. Hayfield, Plat. Met. Rev. 42, 1998, 46