A forge is a type of hearth used for heating metals, or the workplace (smithy) where such a hearth is located. The forge is used by the smith to heat a piece of metal to a temperature at which it becomes easier to shape by forging, or to the point at which work hardening no longer occurs. The metal is transported to and from the forge using tongs, which are also used to hold the workpiece on the smithy's anvil while the smith works it with a hammer. Sometimes, such as when hardening steel or cooling the work so that it may be handled with bare hands, the workpiece is transported to the slack tub, which rapidly cools the workpiece in a large body of water. However, depending on the metal type, it may require an oil quench or a salt brine instead; many metals require more than plain water hardening. The slack tub also provides water to control the fire in the forge.

A lathe is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis.

A saw is a tool consisting of a tough blade, wire, or chain with a hard toothed edge used to cut through material. Various terms are used to describe toothed and abrasive saws.

A clamp is a fastening device used to hold or secure objects tightly together to prevent movement or separation through the application of inward pressure. In the United Kingdom the term cramp is often used instead when the tool is for temporary use for positioning components during construction and woodworking; thus a G cramp or a sash clamp but a wheel clamp or a surgical clamp.

A workbench is a sturdy table at which manual work is done. They range from simple flat surfaces to very complex designs that may be considered tools in themselves. Workbenches vary in size from tiny jewellers benches to the huge benches used by staircase makers. Almost all workbenches are rectangular in shape, often using the surface, corners and edges as flat/square and dimension standards. Design is as varied as the type of work for which the benches are used but most share these attributes:

The jointer plane, also known as the try plane or trying plane, is a type of hand plane used in woodworking to straighten the edges of boards in the process known as jointing, and to flatten the faces of larger boards. Its long length is designed to 'ride over' the undulations of an uneven surface, skimming off the peaks, gradually creating a flatter surface. In thicknessing or preparing rough stock, the jointer plane is usually preceded by the fore plane or jack plane and followed by the smoothing plane.

A bench dog is a removable clamp used on a woodworking workbench to hold an item fast while being worked. It is characteristically used in concert with an adjustable dog on a bench vise, allowing an item compressed between the two to be held fast on each end, and if offset in both directions.

A vise or vice is a mechanical apparatus used to secure an object to allow work to be performed on it. Vises have two parallel jaws, one fixed and the other movable, threaded in and out by a screw and lever. The jaws are often flat but may have grooves, adapt to the shape of the workpiece or be custom made.

A lathe center, often shortened to center, is a tool that has been ground to a point to accurately position a workpiece on an axis. They usually have an included angle of 60°, but in heavy machining situations an angle of 75° is used.

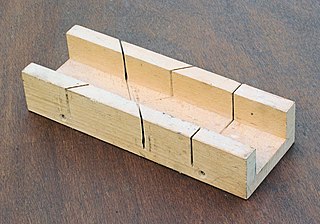

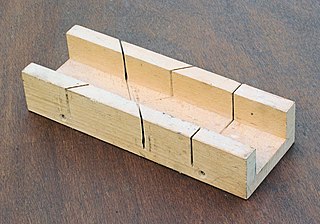

A mitre box or miter box is a wood working appliance used to guide a hand saw for making precise cuts, usually 45° mitre cuts. Traditional mitre boxes are simple in construction and made of wood, while adjustable mitre boxes are made of metal and can be adjusted for cutting any angle from 45° to 90°.

A bench hook is a workbench appliance used in woodworking to hold a workpiece in place while crosscutting with a hand saw. A bench hook is a simple method used to improve accuracy and safety.

A C-clamp or G-clamp or G-cramp is a type of clamp device typically used to hold a wood or metal workpiece, and often used in, but are not limited to, carpentry and welding. Often believed that these clamps are called "C" clamps because of their C-shaped frame, or also often called C-clamps or G-clamps because including the screw part, they are shaped like an uppercase letter G. However, in fact, they were originally called a carriage maker's clamp, or Carriage Clamp.

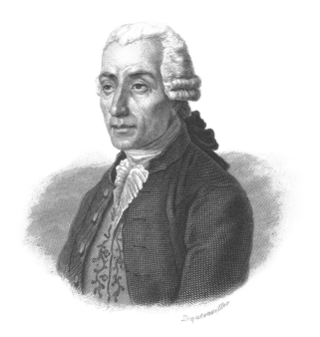

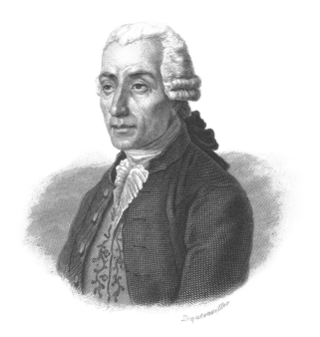

André Jacob Roubo (1739–1791) was a French carpenter, cabinetmaker and author. Roubo was born and died in Paris, and was the son and grandson of master cabinetmakers. Roubo wrote several highly influential books on woodworking, an achievement which was especially notable given his relatively poor background and self-taught methods.

This glossary of woodworking lists a number of specialized terms and concepts used in woodworking, carpentry, and related disciplines.

In engineering, a dog is a tool or part of a tool, such as a pawl, that prevents or imparts movement through physical engagement. It may hold another object in place by blocking it, clamping it, or otherwise obstructing its movement. Or it may couple various parts together so that they move in unison – the primary example of this being a flexible drive to mate two shafts in order to transmit torque. Some devices use dog clutches to lock together two spinning components. In a manual transmission, the dog clutches, or "dogs" lock the selected gear to the shaft it rotates on. Unless the dog is engaged, the gear will simply freewheel on the shaft.

A workbench is a specialized workbench table used by woodworkers. Features include a flat, solid work surface and one or more means of holding the material being worked on.

A shaving horse is a combination of vice and workbench, used for green woodworking. Typical usage of the shaving horse is to create a round profile along a square piece, such as for a chair leg or to prepare a workpiece for the pole lathe. They are used in crafts such as coopering and bowyery.

A veneer hammer is a woodworking tool used in applying veneer.

A router table is a stationary woodworking machine in which a vertically oriented spindle of a woodworking router protrudes from the machine table and can be spun at speeds typically between 3000 and 24,000 rpm. Cutter heads may be mounted in the spindle chuck. As the workpiece is fed into the machine, the cutters mold a profile into it. The machine normally features a vertical fence, against which the workpiece is guided to control the horizontal depth of cut. Router tables are used to increase the versatility of a hand-held router, as each method of use is particularly suited to specific application, e.g. very large workpieces would be too large to support on a router table and must be routed with a hand-held machine, very small workpieces would not support a hand-held router and must be routed on a router table with the aid of pushtool accessories etc.

A woodworking vise is a type of vise adapted to the various needs of woodworkers and woodworking. Several types have evolved to meet differing primary functions, falling under the general categories of front and end vises, reflecting their positions on a workbench.