Electrostatic discharge (ESD) is a sudden and momentary flow of electric current between two differently-charged objects when brought close together or when the dielectric between them breaks down, often creating a visible spark associated with the static electricity between the objects.

Silica gel is an amorphous and porous form of silicon dioxide (silica), consisting of an irregular tridimensional framework of alternating silicon and oxygen atoms with nanometer-scale voids and pores. The voids may contain water or some other liquids, or may be filled by gas or vacuum. In the last case, the material is properly called silica xerogel.

A hygrometer is an instrument which measures the humidity of air or some other gas: that is, how much water vapor it contains. Humidity measurement instruments usually rely on measurements of some other quantities such as temperature, pressure, mass, and mechanical or electrical changes in a substance as moisture is absorbed. By calibration and calculation, these measured quantities can be used to indicate the humidity. Modern electronic devices use the temperature of condensation, or they sense changes in electrical capacitance or resistance.

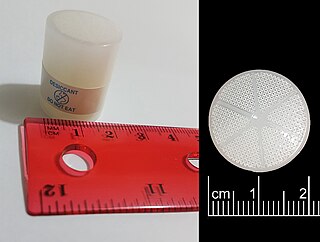

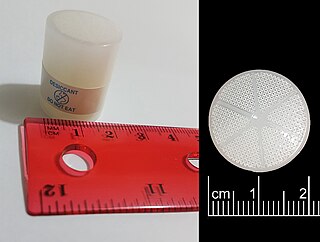

A desiccant is a hygroscopic substance that is used to induce or sustain a state of dryness (desiccation) in its vicinity; it is the opposite of a humectant. Commonly encountered pre-packaged desiccants are solids that absorb water. Desiccants for specialized purposes may be in forms other than solid, and may work through other principles, such as chemical bonding of water molecules. They are commonly encountered in foods to retain crispness. Industrially, desiccants are widely used to control the level of water in gas streams.

MultiMediaCard, officially abbreviated as MMC, is a memory card standard used for solid-state storage. Unveiled in 1997 by SanDisk and Siemens, MMC is based on a surface-contact low-pin-count serial interface using a single memory stack substrate assembly, and is therefore much smaller than earlier systems based on high-pin-count parallel interfaces using traditional surface-mount assembly such as CompactFlash. Both products were initially introduced using SanDisk NOR-based flash technology.

Desiccation is the state of extreme dryness, or the process of extreme drying. A desiccant is a hygroscopic substance that induces or sustains such a state in its local vicinity in a moderately sealed container. The word desiccation comes from Latin de- 'thoroughly' and siccare 'to dry'.

Desiccators are sealable enclosures containing desiccants used for preserving moisture-sensitive items such as cobalt chloride paper for another use. A common use for desiccators is to protect chemicals which are hygroscopic or which react with water from humidity.

A dry box is a storage container in which the interior is kept at a low level of humidity. It may be as simple as an airtight and watertight enclosure, or it may use active means to remove water vapor from the air trapped inside.

A humidifier is a household appliance or device designed to increase the moisture level in the air within a room or an enclosed space. It achieves this by emitting water droplets or steam into the surrounding air, thereby raising the humidity.

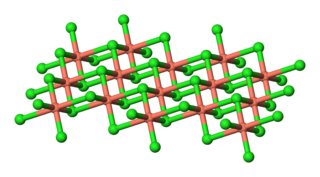

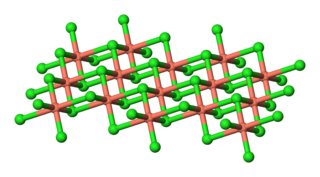

Copper(II) chloride, also known as cupric chloride, is an inorganic compound with the chemical formula CuCl2. The monoclinic yellowish-brown anhydrous form slowly absorbs moisture to form the orthorhombic blue-green dihydrate CuCl2·2H2O, with two water molecules of hydration. It is industrially produced for use as a co-catalyst in the Wacker process.

Moisture sensitivity level (MSL) is a rating that shows a device's susceptibility to damage due to absorbed moisture when subjected to reflow soldering as defined in J-STD-020. It relates to the packaging and handling precautions for some semiconductors. The MSL is an electronic standard for the time period in which a moisture sensitive device can be exposed to ambient room conditions.

Electronic packaging is the design and production of enclosures for electronic devices ranging from individual semiconductor devices up to complete systems such as a mainframe computer. Packaging of an electronic system must consider protection from mechanical damage, cooling, radio frequency noise emission and electrostatic discharge. Product safety standards may dictate particular features of a consumer product, for example, external case temperature or grounding of exposed metal parts. Prototypes and industrial equipment made in small quantities may use standardized commercially available enclosures such as card cages or prefabricated boxes. Mass-market consumer devices may have highly specialized packaging to increase consumer appeal. Electronic packaging is a major discipline within the field of mechanical engineering.

Universal Flash Storage (UFS) is a flash storage specification for digital cameras, mobile phones and consumer electronic devices. It was designed to bring higher data transfer speed and increased reliability to flash memory storage, while reducing market confusion and removing the need for different adapters for different types of cards. The standard encompasses both packages permanently embedded within a device (eUFS), and removable UFS memory cards.

Reliability of a semiconductor device is the ability of the device to perform its intended function during the life of the device in the field.

A semiconductor package is a metal, plastic, glass, or ceramic casing containing one or more discrete semiconductor devices or integrated circuits. Individual components are fabricated on semiconductor wafers before being diced into die, tested, and packaged. The package provides a means for connecting it to the external environment, such as printed circuit board, via leads such as lands, balls, or pins; and protection against threats such as mechanical impact, chemical contamination, and light exposure. Additionally, it helps dissipate heat produced by the device, with or without the aid of a heat spreader. There are thousands of package types in use. Some are defined by international, national, or industry standards, while others are particular to an individual manufacturer.

The Occam process is a solder-free, Restriction of Hazardous Substances Directive (RoHS)-compliant method for use in the manufacturing of electronic circuit boards developed by Verdant Electronics. It combines the usual two steps of constructing printed circuit boards (PCBs) followed by the population process of placing various leaded and non-leaded electronic components into one process. The name "Occam" comes from a quotation by William of Ockham.

In electronics, TO-18 is a designation for a style of transistor metal case. The case is more expensive than the similarly sized plastic TO-92 package. The name is from JEDEC, signifying Transistor Outline Package, Case Style 18.

Electronic components have a wide range of failure modes. These can be classified in various ways, such as by time or cause. Failures can be caused by excess temperature, excess current or voltage, ionizing radiation, mechanical shock, stress or impact, and many other causes. In semiconductor devices, problems in the device package may cause failures due to contamination, mechanical stress of the device, or open or short circuits.

In electronics, a chip carrier is one of several kinds of surface-mount technology packages for integrated circuits. Connections are made on all four edges of a square package; compared to the internal cavity for mounting the integrated circuit, the package overall size is large.

High Bandwidth Memory (HBM) is a computer memory interface for 3D-stacked synchronous dynamic random-access memory (SDRAM) initially from Samsung, AMD and SK Hynix. It is used in conjunction with high-performance graphics accelerators, network devices, high-performance datacenter AI ASICs, as on-package cache in CPUs and on-package RAM in upcoming CPUs, and FPGAs and in some supercomputers. The first HBM memory chip was produced by SK Hynix in 2013, and the first devices to use HBM were the AMD Fiji GPUs in 2015.