Related Research Articles

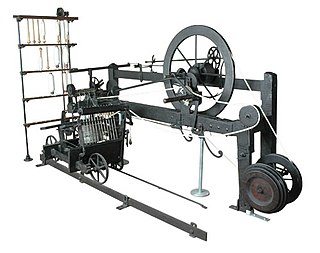

The Industrial Revolution, also known as the First Industrial Revolution, was a period of global transition of the human economy towards more widespread, efficient and stable manufacturing processes that succeeded the Agricultural Revolution, starting from Great Britain, continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going from hand production methods to machines; new chemical manufacturing and iron production processes; the increasing use of water power and steam power; the development of machine tools; and the rise of the mechanized factory system. Output greatly increased, and the result was an unprecedented rise in population and the rate of population growth. The textile industry was the first to use modern production methods, and textiles became the dominant industry in terms of employment, value of output, and capital invested.

Derwent Valley Mills is a World Heritage Site along the River Derwent in Derbyshire, England, designated in December 2001. It is administered by the Derwent Valley Mills Partnership. The modern factory, or 'mill', system was born here in the 18th century to accommodate the new technology for spinning cotton developed by Richard Arkwright. With advancements in technology, it became possible to produce cotton continuously. The system was adopted throughout the valley, and later spread so that by 1788 there were over 200 Arkwright-type mills in Britain. Arkwright's inventions and system of organising labour was exported to Europe and the United States.

Quarry Bank Mill in Styal, Cheshire, England, is one of the best preserved textile factories of the Industrial Revolution. Built in 1784, the cotton mill is recorded in the National Heritage List for England as a designated Grade II* listed building. Quarry Bank Mill was established by Samuel Greg, and was notable for innovations both in machinery and also in its approach to labour relations, the latter largely as a result of the work of Greg's wife, Hannah Lightbody. The family took a somewhat paternalistic attitude toward the workers, providing medical care for all and limited education to the children, but all laboured roughly 72 hours per week until 1847 when a new law shortened the hours.

A cotton mill is a building that houses spinning or weaving machinery for the production of yarn or cloth from cotton, an important product during the Industrial Revolution in the development of the factory system.

Textile manufacture during the British Industrial Revolution was centred in south Lancashire and the towns on both sides of the Pennines in the United Kingdom. The main drivers of the Industrial Revolution were textile manufacturing, iron founding, steam power, oil drilling, the discovery of electricity and its many industrial applications, the telegraph and many others. Railroads, steamboats, the telegraph and other innovations massively increased worker productivity and raised standards of living by greatly reducing time spent during travel, transportation and communications.

Improvements to the steam engine were some of the most important technologies of the Industrial Revolution, although steam did not replace water power in importance in Britain until after the Industrial Revolution. From Englishman Thomas Newcomen's atmospheric engine, of 1712, through major developments by Scottish inventor and mechanical engineer James Watt, the steam engine began to be used in many industrial settings, not just in mining, where the first engines had been used to pump water from deep workings. Early mills had run successfully with water power, but by using a steam engine a factory could be located anywhere, not just close to a water source. Water power varied with the seasons and was not always available.

The Barton Swing Aqueduct is a moveable navigable aqueduct in Barton upon Irwell, Greater Manchester, England. It carries the Bridgewater Canal across the Manchester Ship Canal. The swinging action allows large vessels using the ship canal to pass through and smaller craft, both narrowboats and broad-beam barges, to cross over the top. The aqueduct, the first and only swing aqueduct in the world, is a Grade II* listed building, and considered a major feat of Victorian civil engineering. Designed by Sir Edward Leader Williams and built by Andrew Handyside and Company of Derby, the swing bridge opened in 1894 and remains in regular use.

The textile industry is primarily concerned with the design, production and distribution of textiles: yarn, cloth and clothing. The raw material may be natural, or synthetic using products of the chemical industry.

Cottonopolis was a 19th-century nickname for Manchester, as it was a metropolis and the centre of the cotton industry.

The Manchester warehouse which we lately visited, was a building fit for the Town Hall of any respectable municipality; a stately, spacious, and tasteful edifice; rich and substantial as its respectable proprietors, the well-known firm of Banneret and Co. There are nearly a hundred such buildings in Manchester; –not so large, perhaps, for this is the largest; but all in their degree worthy of Cottonopolis.

Trencherfield Mill is a cotton spinning mill standing next to the Leeds and Liverpool Canal in Wigan, Greater Manchester, England. It was built in 1907. It was taken over by the Lancashire Cotton Corporation in the 1930s and passed to Courtaulds in 1964. The mill was driven by a 2,500 hp triple-expansion four-cylinder engine built by J & E Wood of Bolton in 1907. The two halves of the engine were called Rina and Helen. They drove a 26-foot flywheel with 54 ropes at 68 rpm. The engine was stopped in 1968. The mill is now part of the Wigan Pier redevelopment area and is used for other purposes.

Murrays' Mills is a complex of former cotton mills on land between Jersey Street and the Rochdale Canal in the district of Ancoats, Manchester, England. The mills were built for brothers Adam and George Murray.

The Old Colony Iron Works-Nemasket Mills Complex is a historic industrial site located on Old Colony Avenue in the East Taunton section of Taunton, Massachusetts, United States, adjacent to the Taunton River at the Raynham town line. The site was first occupied by the Old Colony Iron Company, which had originally been established in the 1820s as Horatio Leonard & Company. The western part of the complex was sold to Nemasket Mills in 1889. The eastern part was acquired by the Standard Oil Cloth Company. The site was added to the National Register of Historic Places in 1984.

Regent Mill, Failsworth is a Grade II listed former cotton spinning mill in Failsworth, Oldham, Greater Manchester, England. It was built by the Regent Mill Co Ltd. in 1905, and purchased by the Lancashire Cotton Corporation in 1930. It was taken over by the Courtaulds Group in 1964. On ceasing textile production it was occupied by Pifco Ltd, and then by Salton Europe Ltd who now occupy this site. It was driven by an 1800 hp twin tandem compound engine by Buckley & Taylor. It became a ring mill with 60,000 spindles in 1915, all provided by Platt Brothers.

The productivity-improving technologies are the technological innovations that have historically increased productivity.

The Weavers' Triangle is an area of Burnley in Lancashire, England consisting mostly of 19th-century industrial buildings at the western side of town centre clustered around the Leeds and Liverpool Canal. The area has significant historic interest as the cotton mills and associated buildings encapsulate the social and economic development of the town and its weaving industry. From the 1980s, the area has been the focus of major redevelopment efforts.

Ellenroad Mill was a cotton spinning mill in Newhey, a village in the Milnrow area of Rochdale, England. It was built as a mule spinning mill in 1890 by Stott and Sons and extended in 1899. It was destroyed by fire on 19 January 1916. When it was rebuilt, it was designed and equipped as a ring spinning mill.

Industrial architecture is the design and construction of buildings facilitating the needs of the industrial sector. The architecture revolving around the industrial world uses a variety of building designs and styles to consider the safe flow, distribution and production of goods and labor. Such buildings rose in importance with the Industrial Revolution, starting in Britain, and were some of the pioneering structures of modern architecture. Many of the architectural buildings revolving around the industry allowed for processing, manufacturing, distribution, and the storage of goods and resources. Architects also have to consider the safety measurements and workflow to ensure the smooth flow within the work environment located in the building.

The Merthyr Tramroad was a 9.75-mile-long (15.69 km) line that opened in 1802, connecting the private lines belonging to the Dowlais and Penydarren Ironworks with the Glamorganshire Canal at Abercynon, also serving the Plymouth Ironworks along the way. Famous as the line on which Richard Trevithick's experimental locomotive hauled the first train to carry a load. It was largely superseded when the Taff Vale Railway opened in 1841 and sections gradually went out of use over the two decades from about 1851.

In Scotland, the Industrial Revolution was the transition to new manufacturing processes and economic expansion between the mid-eighteenth century and the late nineteenth century. By the start of the eighteenth century, a political union between Scotland and England became politically and economically attractive, promising to open up the much larger markets of England, as well as those of the growing British Empire, resulting in the Treaty of Union of 1707. There was a conscious attempt among the gentry and nobility to improve agriculture in Scotland. New crops were introduced and enclosures began to displace the run rig system and free pasture. The economic benefits of union were very slow to appear, some progress was visible, such as the sales of linen and cattle to England, the cash flows from military service, and the tobacco trade that was dominated by Glasgow after 1740. Merchants who profited from the American trade began investing in leather, textiles, iron, coal, sugar, rope, sailcloth, glass-works, breweries, and soap-works, setting the foundations for the city's emergence as a leading industrial center after 1815.

British industrial architecture has been created, mainly from 1700 onwards, to house industries of many kinds in Britain, home of the Industrial Revolution in this period. Both the new industrial technologies and industrial architecture soon spread worldwide. As such, the architecture of surviving industrial buildings records part of the history of the modern world.

References

- ↑ "Industrial Revelations Unofficial Site". Archived from the original on 11 April 2010. Retrieved 24 August 2009.

- ↑ Production company's website

- ↑ Discovery Channel Website