A quality management system (QMS) is a collection of business processes focused on consistently meeting customer requirements and enhancing their satisfaction. It is aligned with an organization's purpose and strategic direction. It is expressed as the organizational goals and aspirations, policies, processes, documented information, and resources needed to implement and maintain it. Early quality management systems emphasized predictable outcomes of an industrial product production line, using simple statistics and random sampling. By the 20th century, labor inputs were typically the most costly inputs in most industrialized societies, so focus shifted to team cooperation and dynamics, especially the early signaling of problems via a continual improvement cycle. In the 21st century, QMS has tended to converge with sustainability and transparency initiatives, as both investor and customer satisfaction and perceived quality are increasingly tied to these factors. Of QMS regimes, the ISO 9000 family of standards is probably the most widely implemented worldwide – the ISO 19011 audit regime applies to both and deals with quality and sustainability and their integration.

A Bachelor of Engineering, Bachelor of Science in Engineering (BSE), or Bachelor of Science and Engineering is an undergraduate academic degree awarded to a college graduate majoring in an engineering discipline at a higher education institution.

Engineering management is the application of engineering methods, tools, and techniques to business management systems. Engineering management is a career that brings together the technological problem-solving ability of engineering and the organizational, administrative, legal and planning abilities of management in order to oversee the operational performance of complex engineering-driven enterprises.

In industry, product lifecycle management (PLM) is the process of managing the entire lifecycle of a product from its inception through the engineering, design and manufacture, as well as the service and disposal of manufactured products. PLM integrates people, data, processes, and business systems and provides a product information backbone for companies and their extended enterprises.

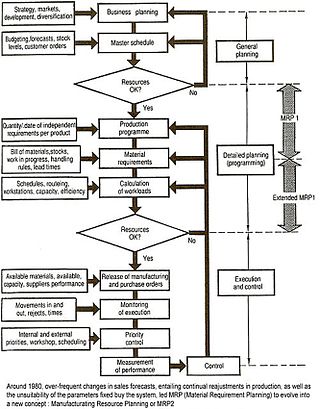

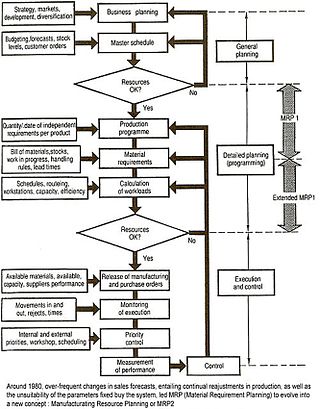

Manufacturingresource planning is a method for the effective planning of all resources of a manufacturing company. Ideally, it addresses operational planning in units, financial planning, and has a simulation capability to answer "what-if" questions and is an extension of closed-loop MRP.

Computer-integrated manufacturing (CIM) is the manufacturing approach of using computers to control the entire production process. This integration allows individual processes to exchange information with each part. Manufacturing can be faster and less error-prone by the integration of computers. Typically CIM relies on closed-loop control processes based on real-time input from sensors. It is also known as flexible design and manufacturing.

Operations management is concerned with designing and controlling the production of goods and services, ensuring that businesses are efficient in using resources to meet customer requirements.

Computer-aided production engineering (CAPE) is a relatively new and significant branch of engineering. Global manufacturing has changed the environment in which goods are produced. Meanwhile, the rapid development of electronics and communication technologies has required design and manufacturing to keep pace.

The Association of Technology, Management and Applied Engineering (ATMAE) is an association in the United States. ATMAE sets standards for academic program accreditation, personal certification and professional development for educators and industry professionals involved in integrating technology, leadership and design.

Enterprise modelling is the abstract representation, description and definition of the structure, processes, information and resources of an identifiable business, government body, or other large organization.

The Faculty of Data and Decision Sciences is an academic faculty of the Technion and the oldest such department in Israel. The department is currently headed by Prof. Rann Smorodinsky and is based in the Cooper and Bloomfield buildings at Technion City. The department employs 52 faculty members, who as of 2023 served a total of 500 graduate and 1000 undergraduate students.

Packaging engineering, also package engineering, packaging technology and packaging science, is a broad topic ranging from design conceptualization to product placement. All steps along the manufacturing process, and more, must be taken into account in the design of the package for any given product. Package engineering is an interdisciplinary field integrating science, engineering, technology and management to protect and identify products for distribution, storage, sale, and use. It encompasses the process of design, evaluation, and production of packages. It is a system integral to the value chain that impacts product quality, user satisfaction, distribution efficiencies, and safety. Package engineering includes industry-specific aspects of industrial engineering, marketing, materials science, industrial design and logistics. Packaging engineers must interact with research and development, manufacturing, marketing, graphic design, regulatory, purchasing, planning and so on. The package must sell and protect the product, while maintaining an efficient, cost-effective process cycle.

Industrial technology is the use of engineering and manufacturing technology to make production faster, simpler, and more efficient. The industrial technology field employs creative and technically proficient individuals who can help a company achieve efficient and profitable productivity.

The Toyota Way is a set of principles defining the organizational culture of Toyota Motor Corporation. The company formalized the Toyota Way in 2001, after decades of academic research into the Toyota Production System and its implications for lean manufacturing as a methodology that other organizations could adopt. The two pillars of the Toyota Way are respect for people and continuous improvement. Jeffrey K. Liker popularized the philosophy in his 2004 book, The Toyota Way: 14 Management Principles from the World's Greatest Manufacturer. Subsequent research has explored the extent to which the Toyota Way can be applied in other contexts.

Manufacturing engineering or production engineering is a branch of professional engineering that shares many common concepts and ideas with other fields of engineering such as mechanical, chemical, electrical, and industrial engineering. Manufacturing engineering requires the ability to plan the practices of manufacturing; to research and to develop tools, processes, machines, and equipment; and to integrate the facilities and systems for producing quality products with the optimum expenditure of capital.

Enterprise engineering is the body of knowledge, principles, and practices used to design all or part of an enterprise. An enterprise is a complex socio-technical system that comprises people, information, and technology that interact with each other and their environment in support of a common mission. One definition is: "an enterprise life-cycle oriented discipline for the identification, design, and implementation of enterprises and their continuous evolution", supported by enterprise modelling. The discipline examines each aspect of the enterprise, including business processes, information flows, material flows, and organizational structure. Enterprise engineering may focus on the design of the enterprise as a whole, or on the design and integration of certain business components.

Industrial engineering is an engineering profession that is concerned with the optimization of complex processes, systems, or organizations by developing, improving and implementing integrated systems of people, money, knowledge, information and equipment. Industrial engineering is central to manufacturing operations.

Applied engineering prepares graduates to apply mathematics, science, technology, and engineering methods to manage, or support engineering functions. Includes instruction in engineering management, project management, six sigma, production, operations management, systems engineering, auto cad, basic programming, and quality control. The additional application of system design, testing, repairing products, execution of new product designs, and improvement of manufacturing processes.

Industrial and production engineering (IPE) is an interdisciplinary engineering discipline that includes manufacturing technology, engineering sciences, management science, and optimization of complex processes, systems, or organizations. It is concerned with the understanding and application of engineering procedures in manufacturing processes and production methods. Industrial engineering dates back all the way to the industrial revolution, initiated in 1700s by Sir Adam Smith, Henry Ford, Eli Whitney, Frank Gilbreth and Lilian Gilbreth, Henry Gantt, F.W. Taylor, etc. After the 1970s, industrial and production engineering developed worldwide and started to widely use automation and robotics. Industrial and production engineering includes three areas: Mechanical engineering, industrial engineering, and management science.

Industrial artificial intelligence, or industrial AI, usually refers to the application of artificial intelligence to industry and business. Unlike general artificial intelligence which is a frontier research discipline to build computerized systems that perform tasks requiring human intelligence, industrial AI is more concerned with the application of such technologies to address industrial pain-points for customer value creation, productivity improvement, cost reduction, site optimization, predictive analysis and insight discovery.