A Bunsen burner, named after Robert Bunsen, is a kind of ambient air gas burner used as laboratory equipment; it produces a single open gas flame, and is used for heating, sterilization, and combustion.

A carburetor is a device used by a gasoline internal combustion engine to control and mix air and fuel entering the engine. The primary method of adding fuel to the intake air is through the Venturi tube in the main metering circuit, though various other components are also used to provide extra fuel or air in specific circumstances.

Flow measurement is the quantification of bulk fluid movement. Flow can be measured using devices called flowmeters in various ways. The common types of flowmeters with industrial applications are listed below:

A nozzle is a device designed to control the direction or characteristics of a fluid flow as it exits an enclosed chamber or pipe.

A combustion chamber is part of an internal combustion engine in which the fuel/air mix is burned. For steam engines, the term has also been used for an extension of the firebox which is used to allow a more complete combustion process.

A tap is a valve controlling the release of a fluid.

The Zenith Carburetter Company Limited was a British company making carburettors in Stanmore Middlesex, founded in 1912 as a subsidiary of the French Société du carburateur Zénith. In 1965, the company joined with its major pre-war rival Solex Carburettors, and over time, the Zenith brand name fell into disuse. The rights to the Zenith designs were owned by Solex UK.

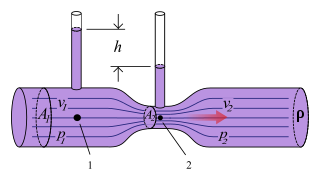

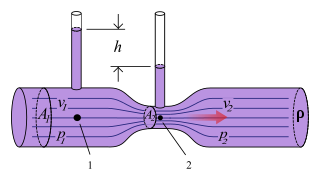

The Venturi effect is the reduction in fluid pressure that results when a fluid flows through a constricted section of a pipe. The Venturi effect is named after its discoverer, the 18th-century Italian physicist Giovanni Battista Venturi.

A gas lift or bubble pump is a type of pump that can raise fluid between elevations by introducing gas bubbles into a vertical outlet tube; as the bubbles rise within the tube they cause a drop in the hydrostatic pressure behind them, causing the fluid to be pulled up. Gas lifts are commonly used as artificial lifts for water or oil, using compressed air or water vapor.

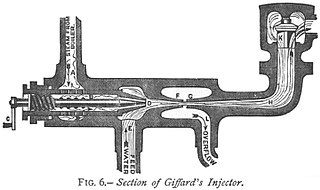

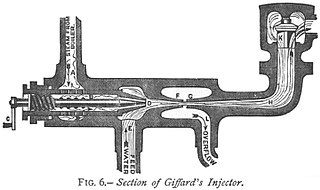

An injector is a system of ducting and nozzles used to direct the flow of a high-pressure fluid in such a way that a lower pressure fluid is entrained in the jet and carried through a duct to a region of higher pressure. It is a fluid-dynamic pump with no moving parts except a valve to control inlet flow.

A fire-tube boiler is a type of boiler invented in 1828 by Mark Seguin, in which hot gases pass from a fire through one or more tubes running through a sealed container of water. The heat of the gases is transferred through the walls of the tubes by thermal conduction, heating the water and ultimately creating steam.

A needle valve is a type of valve with a small port and a threaded, needle-shaped plunger. It allows precise regulation of flow, although it is generally only capable of relatively low flow rates.

An air flow bench is a device used for testing the internal aerodynamic qualities of an engine component and is related to the more familiar wind tunnel.

An oil burner is a heating device which burns #1, #2 and #6 heating oils, diesel fuel or other similar fuels. In the United States, ultra low sulfur #2 diesel is the common fuel used. It is dyed red to show that it is road-tax exempt. In most markets of the United States, heating oil is the same specification of fuel as on-road un-dyed diesel.

Artificial lift refers to the use of artificial means to increase the flow of liquids, such as crude oil or water, from a production well. Generally this is achieved by the use of a mechanical device inside the well or by decreasing the weight of the hydrostatic column by injecting gas into the liquid some distance down the well. A newer method called Continuous Belt Transportation (CBT) uses an oil absorbing belt to extract from marginal and idle wells. Artificial lift is needed in wells when there is insufficient pressure in the reservoir to lift the produced fluids to the surface, but often used in naturally flowing wells to increase the flow rate above what would flow naturally. The produced fluid can be oil, water or a mix of oil and water, typically mixed with some amount of gas.

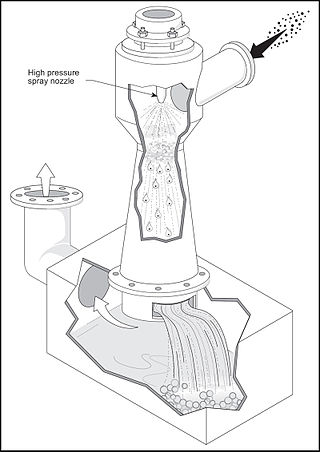

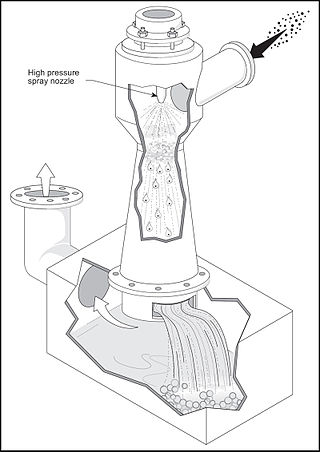

A venturi scrubber is designed to effectively use the energy from a high-velocity inlet gas stream to atomize the liquid being used to scrub the gas stream. This type of technology is a part of the group of air pollution controls collectively referred to as wet scrubbers.

Turndown ratio refers to the width of the operational range of a device, and is defined as the ratio of the maximum capacity to minimum capacity. For example, a device with a maximum output of 10 units and a minimum output of 2 units has a turndown ratio of 5. The term is commonly used with measurement devices and combustion plant like boilers and gasifiers.

A Meker–Fisher burner, or Meker burner, is an ambient air laboratory burner that produces multiple open gas flames, used for heating, sterilization, and combustion. It is used when laboratory work requires a hotter flame than attainable using a Bunsen burner, or used when a larger-diameter flame is desired, such as with an inoculation loop or in some glassblowing operations. The burner was introduced by French chemist Georges Méker in an article published in 1905.

A spray is a dynamic collection of drops dispersed in a gas. The process of forming a spray is known as atomization. A spray nozzle is the device used to generate a spray. The two main uses of sprays are to distribute material over a cross-section and to generate liquid surface area. There are thousands of applications in which sprays allow material to be used most efficiently. The spray characteristics required must be understood in order to select the most appropriate technology, optimal device and size.

Of the three types of carburetors used on large, high-performance aircraft engines manufactured in the United States during World War II, the Bendix-Stromberg pressure carburetor was the one most commonly found. The other two carburetor types were manufactured by Chandler Groves and Chandler Evans Control Systems (CECO). Both of these types of carburetors had a relatively large number of internal parts, and in the case of the Holley Carburetor, there were complications in its "variable venturi" design.