Prestressed concrete is a form of concrete used in construction that while under construction is substantially "prestressed" (compressed) in the areas that will be subjected to tensile forces while in service to strengthen it against these forces.

A slip joint is a mechanical construction allowing extension and compression in a linear structure.

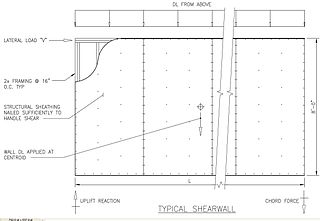

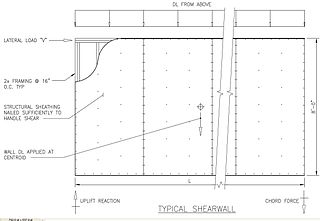

In structural engineering, a shear wall is a vertical element of a seismic force resisting system that is designed to resist in-plane lateral forces, typically wind and seismic loads. In many jurisdictions, the International Building Code and International Residential Code govern the design of shear walls.

A plate girder bridge is a bridge supported by two or more plate girders.

Steel frame is a building technique with a "skeleton frame" of vertical steel columns and horizontal I-beams, constructed in a rectangular grid to support the floors, roof and walls of a building which are all attached to the frame. The development of this technique made the construction of the skyscraper possible.

An extradosed bridge employs a structure that combines the main elements of both a prestressed box girder bridge and a cable-stayed bridge. The name comes from the word extrados, the exterior or upper curve of an arch, and refers to how the "stay cables" on an extradosed bridge are not considered as such in the design, but are instead treated as external prestressing tendons deviating upward from the deck. In this concept, they remain part of the main bridge superstructure.

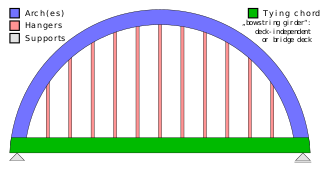

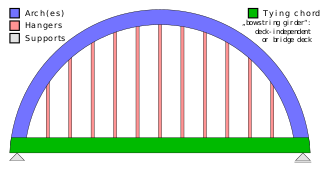

A tied-arch bridge is an arch bridge in which the outward-directed horizontal forces of the arch(es) are borne as tension by a chord tying the arch ends, rather than by the ground or the bridge foundations. This strengthened chord may be the deck structure itself or consist of separate, deck-independent tie-rods.

A girder bridge is a bridge that uses girders as the means of supporting its deck. The two most common types of modern steel girder bridge are plate and box.

The Schierstein Bridge is 1,282-meter (4,206 ft) long, four-lane highway bridge in Germany. It carries Bundesautobahn 643 over the Rhine River between Mainz-Mombach, Rhineland-Palatinate and Wiesbaden-Schierstein, Hesse. Crossing two arms of the Rhine and the intervening island of Rettbergsaue, the bridge is made of six individual structures, including 100 m (330 ft) from prestressed concrete. It was built between 1959 and 1962.

The Hadley Parabolic Bridge, often referred to locally as the Hadley Bow Bridge, carries Corinth Road across the Sacandaga River in Hadley, New York, United States. It is an iron bridge dating from the late 19th century.

A pipe support or pipe hanger is a designed element that transfer the load from a pipe to the supporting structures. The load includes the weight of the pipe proper, the content that the pipe carries, all the pipe fittings attached to pipe, and the pipe covering such as insulation. The four main functions of a pipe support are to anchor, guide, absorb shock, and support a specified load. Pipe supports used in high or low temperature applications may contain insulation materials. The overall design configuration of a pipe support assembly is dependent on the loading and operating conditions.

Vidyasagar Setu, also known as the Second Hooghly Bridge, is a toll bridge over the Hooghly River in West Bengal, India, linking the cities of Kolkata and Howrah.

Aircraft bridges, including taxiway bridges and runway bridges, bring aircraft traffic over motorways, railways, and waterways, and must be designed to support the heaviest aircraft that may cross them. In 1963, a taxiway bridge at Chicago O'Hare Airport, one of the busiest airports in the world, was planned to handle future aircraft weighing 365,000 pounds (166,000 kg), but aircraft weights doubled within two years of its construction. Currently, the largest passenger aircraft in the world, the Airbus A380, has a maximum take-off weight (MTOW) of 575 t (1,268,000 lb). The largest Boeing planes, i.e. the current "Project Ozark" versions of the Boeing 747-8, are approaching MTOW of greater than 1,000,000 lb (450,000 kg). Aircraft bridges must be designed for the substantial forces exerted by aircraft braking, affecting the lateral load in substructure design. Braking force of 70 percent of the live load is assumed in two recent taxiway bridge designs. And "deck design is more apt to be controlled by punching shear than flexure due to the heavy wheel loads."

Clackline Bridge is a road bridge in Clackline, Western Australia, 77 kilometres (48 mi) east of Perth in the Shire of Northam, that carried the Great Eastern Highway until 2008. It is the only bridge in Western Australia to have spanned both a waterway and railway, the Clackline Brook and the former Eastern Railway alignment. The mainly timber bridge has a unique curved and sloped design, due to the difficult topography and the route of the former railway. The bridge was designed in 1934 to replace two dangerous rail crossings and a rudimentary water crossing. Construction began in January 1935, and was completed relatively quickly, with the opening ceremony held in August 1935. The bridge has undergone various improvement and maintenance works since then, including widening by three metres (10 ft) in 1959–60, but remained a safety hazard, with increasing severity and numbers of accidents through the 1970s and 1980s. Planning for a highway bypass of Clackline and the Clackline Bridge began in the 1990s, and it was constructed between January 2007 and February 2008. The local community had been concerned that the historic bridge would be lost, but it remains in use as part of the local road network, and has been listed on both the Northam Municipal Heritage Inventory and the Heritage Council of Western Australia's Register of Heritage Places.

A Rigid-frame bridge is a bridge in which the superstructure and substructure are rigidly connected to act as a continuous unit. Typically, the structure is cast monolithically, making the structure continuous from deck to foundation. The connections between members are rigid connections which transfer bending moment, axial forces, and shear forces. A bridge design consisting of a rigid frame can provide significant structural benefits, but can also be difficult to design and/or construct.

The Nipigon River Bridge is a cable-stayed bridge carrying Highway 11 and Highway 17, designated as part of the Trans-Canada Highway, across the Nipigon River near Nipigon, Ontario, Canada.

The Yowaka River bridge is an heritage-listed road bridge that carries the Princes Highway across the Yowaka River at Greigs Flat on the Bega Valley Shire local government area of New South Wales, Australia. It was built in 1936. The bridge is also known as the Yowaka Bridge near Eden. The property is owned by Roads and Maritime Services, an agency of the Government of New South Wales. It was added to the New South Wales State Heritage Register on 20 June 2000.

Structural support is a part of a building or structure providing the necessary stiffness and strength in order to resist the internal forces and guide them safely to the ground. External loads that act on buildings cause internal forces in building support structures. Supports can be either at the end or at any intermediate point along a structural member or a constituent part of a building and they are referred to as connections, joints or restraints.