In commerce, supply chain management (SCM) deals with a system of procurement, operations management, logistics and marketing channels, through which raw materials can be developed into finished products and delivered to their end customers. A more narrow definition of supply chain management is the "design, planning, execution, control, and monitoring of supply chain activities with the objective of creating net value, building a competitive infrastructure, leveraging worldwide logistics, synchronising supply with demand and measuring performance globally". This can include the movement and storage of raw materials, work-in-process inventory, finished goods, and end to end order fulfilment from the point of origin to the point of consumption. Interconnected, interrelated or interlinked networks, channels and node businesses combine in the provision of products and services required by end customers in a supply chain.

The Lockheed Martin Corporation is an American aerospace and defense manufacturer with worldwide interests. It was formed by the merger of Lockheed Corporation with Martin Marietta in March 1995. It is headquartered in North Bethesda, Maryland. As of January 2022, Lockheed Martin employs approximately 115,000 employees worldwide, including about 60,000 engineers and scientists.

AB SKF is a Swedish bearing and seal manufacturing company founded in Gothenburg, Sweden, in 1907. The company manufactures and supplies bearings, seals, lubrication and lubrication systems, maintenance products, mechatronics products, power transmission products, condition monitoring systems and related services globally.

Tesco plc is a British multinational groceries and general merchandise retailer headquartered in Welwyn Garden City, England. The company was founded by Jack Cohen in Hackney, London in 1919. In 2011, it was the third-largest retailer in the world measured by gross revenues and the ninth-largest in the world measured by revenues. It has shops in Ireland, the United Kingdom, the Czech Republic, Hungary, and Slovakia. It is the market leader of groceries in the UK.

A supply chain is a complex logistics system that consists of facilities that convert raw materials into finished products and distribute them to end consumers or end customers. Meanwhile, supply chain management deals with the flow of goods in distribution channels within the supply chain in the most efficient manner.

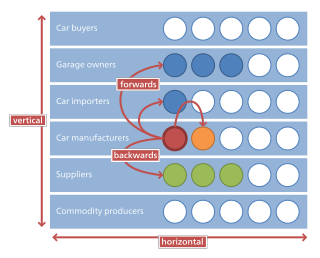

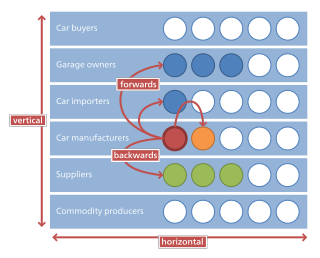

In microeconomics, management and international political economy, vertical integration, also referred to as vertical consolidation, is an arrangement in which the supply chain of a company is integrated and owned by that company. Usually each member of the supply chain produces a different product or (market-specific) service, and the products combine to satisfy a common need. It contrasts with horizontal integration, wherein a company produces several items that are related to one another. Vertical integration has also described management styles that bring large portions of the supply chain not only under a common ownership but also into one corporation.

Lean manufacturing is a method of manufacturing goods aimed primarily at reducing times within the production system as well as response times from suppliers and customers. It is closely related to another concept called just-in-time manufacturing. Just-in-time manufacturing tries to match production to demand by only supplying goods that have been ordered and focus on efficiency, productivity, and reduction of "wastes" for the producer and supplier of goods. Lean manufacturing adopts the just-in-time approach and additionally focuses on reducing cycle, flow, and throughput times by further eliminating activities that do not add any value for the customer. Lean manufacturing also involves people who work outside of the manufacturing process, such as in marketing and customer service.

Six Sigma (6σ) is a set of techniques and tools for process improvement. It was introduced by American engineer Bill Smith while working at Motorola in 1986.

Marketing strategy refers to efforts undertaken by an organization to increase its sales and achieve competitive advantage.

A value chain is a progression of activities that a business or firm performs in order to deliver goods and services of value to an end customer. The concept comes from the field of business management and was first described by Michael Porter in his 1985 best-seller, Competitive Advantage: Creating and Sustaining Superior Performance.

The idea of [Porter's Value Chain] is based on the process view of organizations, the idea of seeing a manufacturing organization as a system, made up of subsystems each with inputs, transformation processes and outputs. Inputs, transformation processes, and outputs involve the acquisition and consumption of resources – money, labour, materials, equipment, buildings, land, administration and management. How value chain activities are carried out determines costs and affects profits.

Corporate social responsibility (CSR) or corporate social impact is a form of international private business self-regulation which aims to contribute to societal goals of a philanthropic, activist, or charitable nature by engaging in, with, or supporting professional service volunteering through pro bono programs, community development, administering monetary grants to non-profit organizations for the public benefit, or to conduct ethically oriented business and investment practices. While once it was possible to describe CSR as an internal organizational policy or a corporate ethic strategy similar to what is now known today as Environmental, Social, Governance (ESG); that time has passed as various companies have pledged to go beyond that or have been mandated or incentivized by governments to have a better impact on the surrounding community. In addition, national and international standards, laws, and business models have been developed to facilitate and incentivize this phenomenon. Various organizations have used their authority to push it beyond individual or industry-wide initiatives. In contrast, it has been considered a form of corporate self-regulation for some time, over the last decade or so it has moved considerably from voluntary decisions at the level of individual organizations to mandatory schemes at regional, national, and international levels. Moreover, scholars and firms are using the term "creating shared value", an extension of corporate social responsibility, to explain ways of doing business in a socially responsible way while making profits.

Service management in the manufacturing context, is integrated into supply chain management as the intersection between the actual sales and the customer point of view. The aim of high-performance service management is to optimize the service-intensive supply chains, which are usually more complex than the typical finished-goods supply chain. Most service-intensive supply chains require larger inventories and tighter integration with field service and third parties. They also must accommodate inconsistent and uncertain demand by establishing more advanced information and product flows. Moreover, all processes must be coordinated across numerous service locations with large numbers of parts and multiple levels in the supply chain.

Reverse logistics encompasses all operations related to the upstream movement of products and materials. It is "the process of moving goods from their typical final destination for the purpose of capturing value, or proper disposal. Remanufacturing and refurbishing activities also may be included in the definition of reverse logistics." Growing green concerns and advancement of green supply chain management concepts and practices make it all the more relevant. The number of publications on the topic of reverse logistics have increased significantly over the past two decades. The first use of the term "reverse logistics" in a publication was by James R. Stock in a White Paper titled "Reverse Logistics," published by the Council of Logistics Management in 1992. The concept was further refined in subsequent publications by Stock (1998) in another Council of Logistics Management book, titled Development and Implementation of Reverse Logistics Programs, and by Rogers and Tibben-Lembke (1999) in a book published by the Reverse Logistics Association titled Going Backwards: Reverse Logistics Trends and Practices. The reverse logistics process includes the management and the sale of surplus as well as returned equipment and machines from the hardware leasing business. Normally, logistics deal with events that bring the product towards the customer. In the case of reverse logistics, the resource goes at least one step back in the supply chain. For instance, goods move from the customer to the distributor or to the manufacturer.

Safety stock is a term used by logisticians to describe a level of extra stock that is maintained to mitigate risk of stockouts caused by uncertainties in supply and demand. Adequate safety stock levels permit business operations to proceed according to their plans. Safety stock is held when uncertainty exists in demand, supply, or manufacturing yield, and serves as an insurance against stockouts.

DHL Supply Chain is a division of Deutsche Post DHL and is affiliated with DHL. Headquartered in Bonn, Deutsche Post has 510,000 employees.

ISO 22000 is a food safety management system by the International Organization for Standardization (ISO) which is outcome focused, providing requirements for any organization in the food industry with objective to help to improve overall performance in food safety. These standards are intended to ensure safety in the global food supply chain. The standards involve the overall guidelines for food safety management and also focuses on traceability in the feed and food chain.

Quick response manufacturing (QRM) is an approach to manufacturing which emphasizes the beneficial effect of reducing internal and external lead times.

Digital transformation (DT) is the process of adoption and implementation of digital technology by an organization in order to create new or modify existing products, services and operations by the means of translating business processes into a digital format.

Third-party logistics is an organization's long term commitment of outsourcing its distribution services to third-party logistics businesses.

SMART-S Mk2(Signaal Multibeam Acquisition Radar for Tracking, S band Mk2) is a naval medium to long-range air and surface surveillance multibeam passive electronically scanned array 3D radar designed by Thales Nederland, formerly Hollandse Signaalapparaten (Signaal). While the original SMART-S radar was only produced in small numbers, SMART-S Mk2 is more successful with 30 systems were sold to navies all over the world within six years after being introduced. The radar transmitter/receiver (T/R) modules for the radar are purchased by Thales from the Turkish defence company Aselsan.