Related Research Articles

In commerce, supply chain management (SCM) deals with a system of procurement, operations management, logistics and marketing channels, through which raw materials can be developed into finished products and delivered to their end customers. A more narrow definition of supply chain management is the "design, planning, execution, control, and monitoring of supply chain activities with the objective of creating net value, building a competitive infrastructure, leveraging worldwide logistics, synchronising supply with demand and measuring performance globally". This can include the movement and storage of raw materials, work-in-process inventory, finished goods, and end to end order fulfilment from the point of origin to the point of consumption. Interconnected, interrelated or interlinked networks, channels and node businesses combine in the provision of products and services required by end customers in a supply chain.

A supply chain is a complex logistics system that consists of facilities that convert raw materials into finished products and distribute them to end consumers or end customers. Meanwhile, supply chain management deals with the flow of goods in distribution channels within the supply chain in the most efficient manner.

Outsourcing is a business practice in which companies use external providers to carry out business processes, that would otherwise be handled internally. Outsourcing sometimes involves transferring employees and assets from one firm to another.

Procurement is the process of locating and agreeing to terms and purchasing goods, services, or other works from an external source, often with the use of a tendering or competitive bidding process. The term may also refer to a contractual obligation to "procure", i.e. to "ensure" that something is done. When a government agency buys goods or services through this practice, it is referred to as government procurement or public procurement.

E-procurement is a collective term used to refer to a range of technologies which can be used to automate the internal and external processes associated with procurement, strategic sourcing and purchasing.

A strategic partnership is a relationship between two commercial enterprises, usually formalized by one or more business contracts. A strategic partnership will usually fall short of a legal partnership entity, agency, or corporate affiliate relationship. Strategic partnerships can take on various forms from shake hand agreements, contractual cooperation's all the way to equity alliances, either the formation of a joint venture or cross-holdings in each other.

Supplier relationship management (SRM) is the systematic, enterprise-wide assessment of suppliers' strengths, performance and capabilities with respect to overall business strategy, determination of what activities to engage in with different suppliers, and planning and execution of all interactions with suppliers, in a coordinated fashion across the relationship life cycle, to maximize the value realized through those interactions. The focus of supplier relationship management is the development of two-way, mutually beneficial relationships with strategic supply partners to deliver greater levels of innovation and competitive advantage than could be achieved by operating independently or through a traditional, transactional purchasing arrangement. Underpinning disciplines which support effective SRM include supplier information management, compliance, risk management and performance management.

Procurement outsourcing is the transfer of specified key procurement activities relating to sourcing and supplier management to a third party — perhaps to reduce overall costs or maybe to tighten the company's focus on its core competencies. Procurement categorisation and vendor management of indirect materials and services are typically the most popular outsourced activity.

Bidding is an offer to set a price tag by an individual or business for a product or service or a demand that something be done. Bidding is used to determine the cost or value of something.

Global sourcing is the practice of sourcing from the global market for goods and services across geopolitical boundaries. Global sourcing often aims to exploit global efficiencies in the delivery of a product or service. These efficiencies include low cost skilled labor, low cost raw material, extreme international competition, new technology and other economic factors like tax breaks and low trade tariffs. Common examples of globally sourced products or services include labor-intensive manufactured products produced using low-cost Chinese labor, call centers staffed with low-cost English speaking workers in the Philippines, India and Pakistan, and IT work performed by low-cost programmers in India, Pakistan and Eastern Europe. While these are examples of low-cost country sourcing, global sourcing is not limited to low-cost countries.

Supplier evaluation and supplier appraisal are terms used in business and refer to the process of evaluating and approving potential suppliers by quantitative assessment. The aim of the process is to ensure a portfolio of best-in-class suppliers is available for use. Supplier evaluation can also be applied to current suppliers in order to measure and monitor their performance for the purposes of ensuring contract compliance, reducing costs, mitigating risk and driving continuous improvement.

Spend analysis or spend analytics is the process of collecting, cleansing, classifying and analyzing expenditure data with the purpose of decreasing procurement costs, improving efficiency, and monitoring controls and compliance. It can also be leveraged in other areas of business such as inventory management, contract management, complex sourcing, supplier management, budgeting, planning, and product development.

Procure-to-pay is a term used in the software industry to designate a specific subdivision of the procurement process.

A reverse auction is a type of auction in which the traditional roles of buyer and seller are reversed. Thus, there is one buyer and many potential sellers. In an ordinary auction also known as a forward auction, buyers compete to obtain goods or services by offering increasingly higher prices. In contrast, in a reverse auction, the sellers compete to obtain business from the buyer and prices will typically decrease as the sellers underbid each other.

Vested outsourcing is a hybrid business model in which contracting parties create a formal relational contract using shared values and goals and outcome-based economics to create an agreement that is mutually beneficial for each party. The model was developed out of research by the University of Tennessee led by Kate Vitasek.

An ‘‘‘electronic bidding system ‘‘‘ is an electronic bidding event according to defined negotiation rules (eAgreement). A buyer and two or more suppliers take part in this online event.

Category management is an approach to the organisation of purchasing within a business organisation, also often referred to as procurement. Applying category management to purchasing activity benefits organisations by providing an approach to reduce the cost of buying goods and services, reduce risk in the supply chain, increase overall value from the supply base and gain access to more innovation from suppliers. It is a strategic approach which focuses on the vast majority of organisational spend. If applied effectively throughout an entire organisation, the results can be significantly greater than traditional transactional based purchasing negotiations, however the discipline of category management is sorely misunderstood.

Kate Vitasek is an American author and educator. She is a faculty member for Graduate and Executive Education at the University of Tennessee Haslam College of Business Her research focuses on the Vested outsourcing business model, sourcing business model theory, the relational contract, and collaborative win-win business relationships.

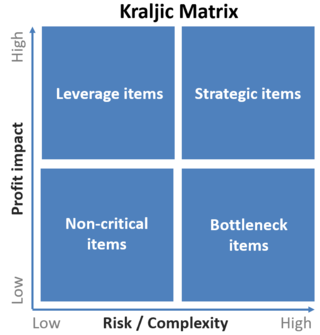

In supply chain management, the Kraljic matrix is a method used to segment the purchases or suppliers of a company by dividing them into four classes, based on the complexity of the supply market and the importance of the purchases or suppliers. This subdivision allows the company to define the optimal purchasing strategies for each of the four types of purchases or suppliers.

José Ignacio López de Arriortúa is a Spanish businessman who held senior positions at Opel, General Motors and Volkswagen. He was known for his assertive style dealing with suppliers, managing lean production and driving down cost.

References

- ↑ Kerruish, Chris (2016). Supply Management: Strategic Sourcing. Springer. ISBN 978-981-10-1722-3.

- ↑ Mayounga, André (2021). "Strategic sourcing in Africa: the case for the labor market". Journal of Global Operations and Strategic Sourcing. 14 (3): 397–413. doi:10.1108/JGOSS-01-2020-0003. S2CID 233790315.

- ↑ Johnson, C., Implementing Strategic Sourcing, Memorandum for Chief Acquisition Officers, Chief Financial Officers, Chief Information Officers, published by the Office of Management and Budget, 20 May 2005, accessed 22 July 2023

- ↑ Nishiguchi, Toshihiro, Strategic Industrial Sourcing (New York: Oxford University, 1994) ISBN 0-19-507109-3

- ↑ Sarangapani, S., Evolving Strategic Sourcing - A Paradigm Shift, accessed 31 January 2021

- ↑ Payne, Joe and Dorn, William (2012), Managing Indirect Spend: Enhancing Profitability Through Strategic Sourcing (John Wiley & Sons, Inc.) ISBN 978-0-470-88688-5

- ↑ Unpacking Competitive Bidding Methods: The Essential ABCs of the Various RFX Methods,|2016|Vested Way|accessed 2 October 2016

- ↑ "Key Success Factors for an Effective Procurement or Purchasing Process | SIPMM Publications". publication.sipmm.edu.sg. 19 July 2018. Retrieved 2022-06-06.

- ↑ Vitasek, Kate; Manrodt, Karl B (2012). Vested: How P&G, McDonald's, and Microsoft are Redefining Winning in Business Relationships (1st ed.). New York: Palgrave Macmillan. ISBN 978-0230341708.

- ↑ Vitasek, Kate; Ledyard, Mike; Manrodt, Karl B (2012). Vested Outsourcing: Five Rules that will Transform Outsourcing . New York: Palgrave Macmillan. ISBN 978-1-137-29719-8.