The Manhattan Project was a research and development undertaking during World War II that produced the first nuclear weapons. It was led by the United States with the support of the United Kingdom and Canada. From 1942 to 1946, the project was under the direction of Major General Leslie Groves of the U.S. Army Corps of Engineers. Nuclear physicist Robert Oppenheimer was the director of the Los Alamos Laboratory that designed the actual bombs. The Army component of the project was designated the Manhattan District as its first headquarters were in Manhattan; the placename gradually superseded the official codename, Development of Substitute Materials, for the entire project. Along the way, the project absorbed its earlier British counterpart, Tube Alloys. The Manhattan Project began modestly in 1939, but grew to employ nearly 130,000 people at its peak and cost nearly US$2 billion. Over 90 percent of the cost was for building factories and to produce fissile material, with less than 10 percent for development and production of the weapons. Research and production took place at more than thirty sites across the United States, the United Kingdom, and Canada.

Isotope separation is the process of concentrating specific isotopes of a chemical element by removing other isotopes. The use of the nuclides produced is varied. The largest variety is used in research. By tonnage, separating natural uranium into enriched uranium and depleted uranium is the largest application. In the following text, mainly the uranium enrichment is considered. This process is crucial in the manufacture of uranium fuel for nuclear power plants, and is also required for the creation of uranium-based nuclear weapons. Plutonium-based weapons use plutonium produced in a nuclear reactor, which must be operated in such a way as to produce plutonium already of suitable isotopic mix or grade. While different chemical elements can be purified through chemical processes, isotopes of the same element have nearly identical chemical properties, which makes this type of separation impractical, except for separation of deuterium.

Enriched uranium is a type of uranium in which the percent composition of uranium-235 has been increased through the process of isotope separation. Naturally occurring uranium is composed of three major isotopes: uranium-238, uranium-235, and uranium-234. 235U is the only nuclide existing in nature that is fissile with thermal neutrons.

Graham's law of effusion was formulated by Scottish physical chemist Thomas Graham in 1848. Graham found experimentally that the rate of effusion of a gas is inversely proportional to the square root of the molar mass of its particles. This formula is stated as:

Willard Frank Libby was an American physical chemist noted for his role in the 1949 development of radiocarbon dating, a process which revolutionized archaeology and palaeontology. For his contributions to the team that developed this process, Libby was awarded the Nobel Prize in Chemistry in 1960.

Tube Alloys was the research and development programme authorised by the United Kingdom, with participation from Canada, to develop nuclear weapons during the Second World War. Starting before the Manhattan Project in the United States, the British efforts were kept classified, and as such had to be referred to by code even within the highest circles of government.

Gaseous diffusion is a technology that was used to produce enriched uranium by forcing gaseous uranium hexafluoride (UF6) through microporous membranes. This produces a slight separation (enrichment factor 1.0043) between the molecules containing uranium-235 (235U) and uranium-238 (238U). By use of a large cascade of many stages, high separations can be achieved. It was the first process to be developed that was capable of producing enriched uranium in industrially useful quantities, but is nowadays considered obsolete, having been superseded by the more-efficient gas centrifuge process.

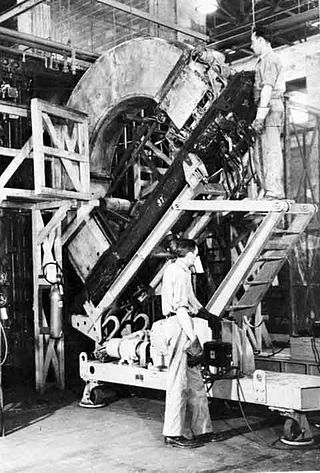

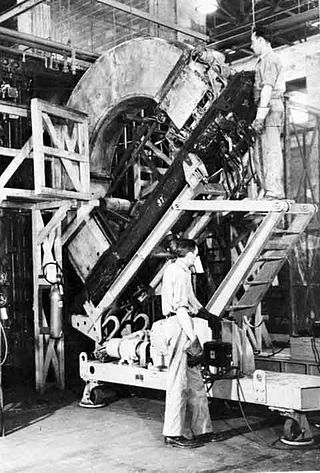

A calutron is a mass spectrometer originally designed and used for separating the isotopes of uranium. It was developed by Ernest Lawrence during the Manhattan Project and was based on his earlier invention, the cyclotron. Its name was derived from California University Cyclotron, in tribute to Lawrence's institution, the University of California, where it was invented. Calutrons were used in the industrial-scale Y-12 uranium enrichment plant at the Clinton Engineer Works in Oak Ridge, Tennessee. The enriched uranium produced was used in the Little Boy atomic bomb that was detonated over Hiroshima on 6 August 1945.

K-25 was the codename given by the Manhattan Project to the program to produce enriched uranium for atomic bombs using the gaseous diffusion method. Originally the codename for the product, over time it came to refer to the project, the production facility located at the Clinton Engineer Works in Oak Ridge, Tennessee, the main gaseous diffusion building, and ultimately the site. When it was built in 1944, the four-story K-25 gaseous diffusion plant was the world's largest building, comprising over 5,264,000 square feet (489,000 m2) of floor space and a volume of 97,500,000 cubic feet (2,760,000 m3).

The Y-12 National Security Complex is a United States Department of Energy National Nuclear Security Administration facility located in Oak Ridge, Tennessee, near the Oak Ridge National Laboratory. It was built as part of the Manhattan Project for the purpose of enriching uranium for the first atomic bombs. It is considered the birthplace of the atomic bomb. In the years after World War II, it has been operated as a manufacturing facility for nuclear weapons components and related defense purposes.

The Manhattan Project was a research and development project that produced the first atomic bombs during World War II. It was led by the United States with the support of the United Kingdom and Canada. From 1942 to 1946, the project was under the direction of Major General Leslie Groves of the US Army Corps of Engineers. The Army component of the project was designated the Manhattan District; "Manhattan" gradually became the codename for the entire project. Along the way, the project absorbed its earlier British counterpart, Tube Alloys. The Manhattan Project began modestly in 1939, but grew to employ more than 130,000 people and cost nearly US$2 billion. Over 90% of the cost was for building factories and producing the fissionable materials, with less than 10% for development and production of the weapons.

The MAUD Committee was a British scientific working group formed during the Second World War. It was established to perform the research required to determine if an atomic bomb was feasible. The name MAUD came from a strange line in a telegram from Danish physicist Niels Bohr referring to his housekeeper, Maud Ray.

The S-50 Project was the Manhattan Project's effort to produce enriched uranium by liquid thermal diffusion during World War II. It was one of three technologies for uranium enrichment pursued by the Manhattan Project.

The Portsmouth Gaseous Diffusion Plant is a facility located in Scioto Township, Pike County, Ohio, just south of Piketon, Ohio, that previously produced enriched uranium, including highly enriched weapons-grade uranium, for the United States Atomic Energy Commission (AEC), the U.S. nuclear weapons program and Navy nuclear propulsion; in later years, it produced low-enriched uranium for fuel for commercial nuclear power reactors. The site never hosted an operating nuclear reactor.

William Taylor Miller was an American professor of organic chemistry at Cornell University. His experimental research included investigations into the mechanism of addition of halogens, especially fluorine, to hydrocarbons. His work focused primarily on the physical and chemical properties of fluorocarbons and chlorofluorocarbons, and the synthesis of novel electrophilic reagents.

The Clinton Engineer Works (CEW) was the production installation of the Manhattan Project that during World War II produced the enriched uranium used in the 1945 bombing of Hiroshima, as well as the first examples of reactor-produced plutonium. It consisted of production facilities arranged at three major sites, various utilities including a power plant, and the town of Oak Ridge. It was in East Tennessee, about 18 miles (29 km) west of Knoxville, and was named after the town of Clinton, eight miles (13 km) to the north. The production facilities were mainly in Roane County, and the northern part of the site was in Anderson County. The Manhattan District Engineer, Kenneth Nichols, moved the Manhattan District headquarters from Manhattan to Oak Ridge in August 1943. During the war, Clinton's advanced research was managed for the government by the University of Chicago.

Britain contributed to the Manhattan Project by helping initiate the effort to build the first atomic bombs in the United States during World War II, and helped carry it through to completion in August 1945 by supplying crucial expertise. Following the discovery of nuclear fission in uranium, scientists Rudolf Peierls and Otto Frisch at the University of Birmingham calculated, in March 1940, that the critical mass of a metallic sphere of pure uranium-235 was as little as 1 to 10 kilograms, and would explode with the power of thousands of tons of dynamite. The Frisch–Peierls memorandum prompted Britain to create an atomic bomb project, known as Tube Alloys. Mark Oliphant, an Australian physicist working in Britain, was instrumental in making the results of the British MAUD Report known in the United States in 1941 by a visit in person. Initially the British project was larger and more advanced, but after the United States entered the war, the American project soon outstripped and dwarfed its British counterpart. The British government then decided to shelve its own nuclear ambitions, and participate in the American project.

Ralph Landau was a chemical engineer and entrepreneur active in the chemical and petrochemical industries. He is considered one of the top fifty foundational chemical engineers of the first half of the 20th century, and one of the 75 most distinguished contributors to chemical enterprise. He has published extensively on chemical engineering and holds a significant number of patents.

The Ames Project was a research and development project that was part of the larger Manhattan Project to build the first atomic bombs during World War II. It was founded by Frank Spedding from Iowa State College in Ames, Iowa as an offshoot of the Metallurgical Laboratory at the University of Chicago devoted to chemistry and metallurgy, but became a separate project in its own right. The Ames Project developed the Ames Process, a method for preparing pure uranium metal that the Manhattan Project needed for its atomic bombs and nuclear reactors. Between 1942 and 1945, it produced over 1,000 short tons (910 t) of uranium metal. It also developed methods of preparing and casting thorium, cerium and beryllium. In October 1945 Iowa State College received the Army-Navy "E" Award for Excellence in Production, an award usually only given to industrial organizations. In 1947 it became the Ames Laboratory, a national laboratory under the Atomic Energy Commission.