A quality management system (QMS) is a collection of business processes focused on consistently meeting customer requirements and enhancing their satisfaction. It is aligned with an organization's purpose and strategic direction. It is expressed as the organizational goals and aspirations, policies, processes, documented information, and resources needed to implement and maintain it. Early quality management systems emphasized predictable outcomes of an industrial product production line, using simple statistics and random sampling. By the 20th century, labor inputs were typically the most costly inputs in most industrialized societies, so focus shifted to team cooperation and dynamics, especially the early signaling of problems via a continual improvement cycle. In the 21st century, QMS has tended to converge with sustainability and transparency initiatives, as both investor and customer satisfaction and perceived quality are increasingly tied to these factors. Of QMS regimes, the ISO 9000 family of standards is probably the most widely implemented worldwide – the ISO 19011 audit regime applies to both and deals with quality and sustainability and their integration.

The ISO 9000 family of quality management systems (QMS) is a set of standards that helps organizations ensure they meet customer and other stakeholder needs within statutory and regulatory requirements related to a product or service. ISO 9000 deals with the fundamentals of QMS, including the seven quality management principles that underlie the family of standards. ISO 9001 deals with the requirements that organizations wishing to meet the standard must fulfill.

ISO 14000 is a family of standards related to environmental management that exists to help organizations (a) minimize how their operations negatively affect the environment ; (b) comply with applicable laws, regulations, and other environmentally oriented requirements; and (c) continually improve in the above.

Nondestructive testing (NDT) is any of a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage. The terms nondestructive examination (NDE), nondestructive inspection (NDI), and nondestructive evaluation (NDE) are also commonly used to describe this technology. Because NDT does not permanently alter the article being inspected, it is a highly valuable technique that can save both money and time in product evaluation, troubleshooting, and research. The six most frequently used NDT methods are eddy-current, magnetic-particle, liquid penetrant, radiographic, ultrasonic, and visual testing. NDT is commonly used in forensic engineering, mechanical engineering, petroleum engineering, electrical engineering, civil engineering, systems engineering, aeronautical engineering, medicine, and art. Innovations in the field of nondestructive testing have had a profound impact on medical imaging, including on echocardiography, medical ultrasonography, and digital radiography.

Quality management ensures that an organization, product or service consistently functions well. It has four main components: quality planning, quality assurance, quality control and quality improvement. Quality management is focused not only on product and service quality, but also on the means to achieve it. Quality management, therefore, uses quality assurance and control of processes as well as products to achieve more consistent quality. Quality control is also part of quality management. What a customer wants and is willing to pay for it, determines quality. It is a written or unwritten commitment to a known or unknown consumer in the market. Quality can be defined as how well the product performs its intended function.

A surface plate is a solid, flat plate used as the main horizontal reference plane for precision inspection, marking out (layout), and tooling setup. The surface plate is often used as the baseline for all measurements to a workpiece, therefore one primary surface is finished extremely flat with tolerances below 11.5 μm or 0.0115 mm per 2960 mm for a grade 0 plate. Surface plates are a common tool in the manufacturing industry and are often fitted with mounting points so that it can be an integrated structural element of a machine such as a coordinate-measuring machine, precision optical assembly, or other high precision scientific & industrial machine. Plates are typically square or rectangular, although they may be cut to any shape.

Hellenic Aerospace Industry (HAI) is the leading aerospace company of Greece. The company headquarters is located in Tanagra, 65 kilometers north-west of Athens, with the industrial complex covering an area of 200,000 sq.m.

ISO 22000 is a Food safety management system which is outcome focused, providing requirements for any organization in the food industry with objective to help to improve overall performance in food safety.

ISO 13485Medical devices -- Quality management systems -- Requirements for regulatory purposes is a voluntary standard, published by International Organization for Standardization (ISO) for the first time in 1996, and contains a comprehensive quality management system for the design and manufacture of medical devices. The latest version of this standard supersedes earlier documents such as EN 46001 and EN 46002 (1996), the previously published ISO 13485, and ISO 13488.

A diamond tool is a cutting tool with diamond grains fixed on the functional parts of the tool via a bonding material or another method. As diamond is a superhard material, diamond tools have many advantages as compared with tools made with common abrasives such as corundum and silicon carbide.

In business, engineering, and manufacturing, quality – or high quality – has a pragmatic interpretation as the non-inferiority or superiority of something ; it is also defined as being suitable for the intended purpose while satisfying customer expectations. Quality is a perceptual, conditional, and somewhat subjective attribute and may be understood differently by different people. Consumers may focus on the specification quality of a product/service, or how it compares to competitors in the marketplace. Producers might measure the conformance quality, or degree to which the product/service was produced correctly. Support personnel may measure quality in the degree that a product is reliable, maintainable, or sustainable. In such ways, the subjectivity of quality is rendered objective via operational definitions and measured with metrics such as proxy measures.

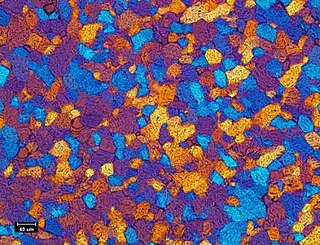

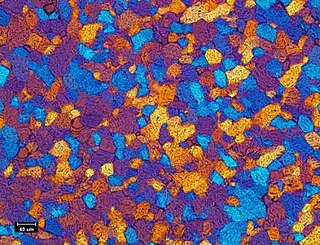

Ceramography is the art and science of preparation, examination and evaluation of ceramic microstructures. Ceramography can be thought of as the metallography of ceramics. The microstructure is the structure level of approximately 0.1 to 100 µm, between the minimum wavelength of visible light and the resolution limit of the naked eye. The microstructure includes most grains, secondary phases, grain boundaries, pores, micro-cracks and hardness microindentions. Most bulk mechanical, optical, thermal, electrical and magnetic properties are significantly affected by the microstructure. The fabrication method and process conditions are generally indicated by the microstructure. The root cause of many ceramic failures is evident in the microstructure. Ceramography is part of the broader field of materialography, which includes all the microscopic techniques of material analysis, such as metallography, petrography and plastography. Ceramography is usually reserved for high-performance ceramics for industrial applications, such as 85–99.9% alumina (Al2O3) in Fig. 1, zirconia (ZrO2), silicon carbide (SiC), silicon nitride (Si3N4), and ceramic-matrix composites. It is seldom used on whiteware ceramics such as sanitaryware, wall tiles and dishware.

Medisafe International is a United Kingdom-based company that develops and manufactures products in the field of surgical instrument reprocessing. In 1985, Medisafe introduced the Sonic Irrigation technology to the medical device market. The company has a representation with manufacturing sites in the UK and offices in Florida, Hamburg, Oslo, Buenos Aires and Malta. Medisafe International won the Millennium Price in Great Britain.

Mishra Dhatu Nigam Limited, is a specialized metals and metal alloys manufacturing facility in India, located in Hyderabad, Telangana. It is a Public Sector Undertaking (PSU), under the administrative control of Department of Defence Production, Ministry of Defence, Government of India. MIDHANI is the only producer of Titanium in India.

Plascore Incorporated manufactures honeycomb core, cleanrooms, and composite panels marketed under the brand Plascore. Honeycomb is used in aerospace, marine, military, safety, transportation, and other applications. When honeycomb is sandwiched between two surfaces, it effectively creates a distance between the two surfaces more or less like an I-beam. The resulting composite structure exhibits a high strength-to-weight ratio and shear strength. Shear strength is the measured ability of a material to resist structural failure. Plascore honeycomb is designed to increase shear strength while adding minimal additional weight. Plascore is a global organization, with a 185,000 sq. ft. headquarters and three additional manufacturing facilities in Zeeland, Michigan. Those three facilities are 50,000, 40,000 and 80,000 sq. ft. in size. The company also has an 85,000 sq. ft. manufacturing plant in Waldlaubersheim, Germany; and sales offices throughout the world. Plascore is AS/EN/JISQ9100, ISO 14001:2004, and ISO 9001:2008 Certified, and the company's PP Honeycomb has received a Lloyds Register Certificate of Approval of a Core Material. Plascore is also AS9100 certified, an industry standard required by the majority of major aircraft manufacturers that provides verification of consistent aerospace product quality.

The McGuff Companies consist of three entities: a wholesale distributor of medical supplies, a compounding pharmacy, and a pharmaceutical manufacturing facility which produces sterile injectables for national and international distribution. The McGuff Companies have been featured in the International Journal of Pharmaceutical Compounding (IJPC).

Precision Dynamics Corporation (PDC) is an American international identification device manufacturer headquartered in Santa Clarita, California with offices abroad in Belgium, France, and the United Kingdom. The company makes identification devices for healthcare, jailing, and entertainment purposes, including wristband and RFID devices.

Fluid Components International (FCI), headquartered in San Marcos, California, is a manufacturer of thermal dispersion flow and level measurement instrumentation. FCI has two divisions, one serving customers with measurement needs in industrial process and plant applications and an aerospace division, which produces level, temperature, flow and pressure sensors for aircraft manufacturers. FCI was a pioneer in developing thermal dispersion technology and holds numerous design and technology patents for its application in flow and level measurement.

Adamant Co., Ltd. is a component manufacturing company based in Tokyo, Japan. Its name is from the word adamant, which was derived from the Greek word adamas meaning "diamond". At of its founding, Adamant's main products were watch jewels that were made of a hard material.

Dormer Pramet is a global manufacturer and supplier of cutting tools for the engineering industry, including drilling, milling, threading and turning tools. Its origins date back to 1913, making it one of the world's oldest specialist manufacturers of engineers cutting tools.