The Unified Thread Standard (UTS) defines a standard thread form and series—along with allowances, tolerances, and designations—for screw threads commonly used in the United States and Canada. It is the main standard for bolts, nuts, and a wide variety of other threaded fasteners used in these countries. It has the same 60° profile as the ISO metric screw thread, but the characteristic dimensions of each UTS thread were chosen as an inch fraction rather than a millimeter value. The UTS is currently controlled by ASME/ANSI in the United States.

American National Standard Pipe Thread standards, often called national pipe thread standards for short, are United States national technical standards for screw threads used on threaded pipes and pipe fittings. They include both tapered and straight thread series for various purposes, including rigidity, pressure-tight sealing, or both. The types are named with a full name and an abbreviation, such as NPT, NPS, NPTF, or NPSC.

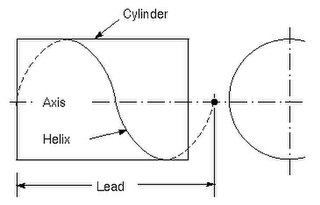

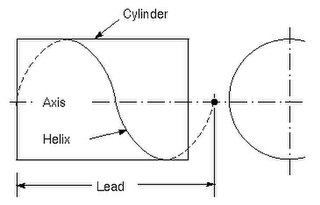

A screw thread is a helical structure used to convert between rotational and linear movement or force. A screw thread is a ridge wrapped around a cylinder or cone in the form of a helix, with the former being called a straight thread and the latter called a tapered thread. A screw thread is the essential feature of the screw as a simple machine and also as a threaded fastener.

British Standard Whitworth (BSW) is an imperial-unit-based screw thread standard, devised and specified by Joseph Whitworth in 1841 and later adopted as a British Standard. It was the world's first national screw thread standard, and is the basis for many other standards, such as BSF, BSP, BSCon, and BSCopper.

British Association screw threads, or BA screw threads, are a set of small screw threads, the largest being 0BA at 6 mm diameter. They were, and to some extent still are, used for miniature instruments and modelling.

A leadscrew, also known as a power screw or translation screw, is a screw used as a linkage in a machine, to translate turning motion into linear motion. Because of the large area of sliding contact between their male and female members, screw threads have larger frictional energy losses compared to other linkages. They are not typically used to carry high power, but more for intermittent use in low power actuator and positioner mechanisms. Leadscrews are commonly used in linear actuators, machine slides, vises, presses, and jacks. Leadscrews are a common component in electric linear actuators.

Trapezoidal thread forms are screw thread profiles with trapezoidal outlines. They are the most common forms used for leadscrews. They offer high strength and ease of manufacture. They are typically found where large loads are required, as in a vise or the leadscrew of a lathe. Standardized variations include multiple-start threads, left-hand threads, and self-centering threads.

A ball screw is a mechanical linear actuator that translates rotational motion to linear motion with little friction. A threaded shaft provides a helical raceway for ball bearings which act as a precision screw. As well as being able to apply or withstand high thrust loads, they can do so with minimum internal friction. They are made to close tolerances and are therefore suitable for high-precision applications. The ball assembly acts as the nut while the threaded shaft is the screw.

The ISO metric screw thread is the most commonly used type of general-purpose screw thread worldwide. They were one of the first international standards agreed when the International Organization for Standardization (ISO) was set up in 1947.

Edison screw (ES) is a standard lightbulb socket for electric light bulbs. It was developed by Thomas Edison (1847–1931), patented in 1881, and was licensed in 1909 under General Electric's Mazda trademark. The bulbs have right-hand threaded metal bases (caps) which screw into matching threaded sockets. For bulbs powered by AC current, the thread is generally connected to neutral and the contact on the bottom tip of the base is connected to the "live" phase.

Lead is the axial advance of a helix or screw during one complete turn (360°) The lead for a screw thread is the axial travel for a single revolution.

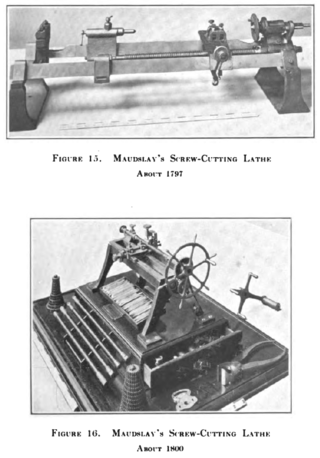

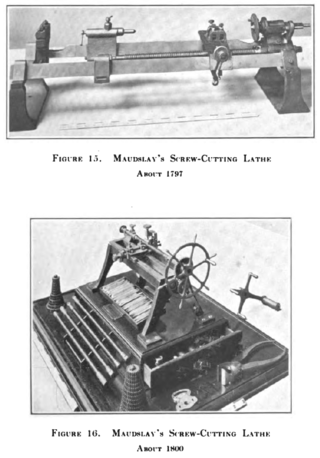

A screw-cutting lathe is a machine capable of cutting very accurate screw threads via single-point screw-cutting, which is the process of guiding the linear motion of the tool bit in a precisely known ratio to the rotating motion of the workpiece. This is accomplished by gearing the leadscrew to the spindle with a certain gear ratio for each thread pitch. Every degree of spindle rotation is matched by a certain distance of linear tool travel, depending on the desired thread pitch.

A screw is an externally helical threaded fastener capable of being tightened or released by a twisting force (torque) to the head. The most common uses of screws are to hold objects together and there are many forms for a variety of materials. Screws might be inserted into holes in assembled parts or a screw may form its own thread. The difference between a screw and a bolt is that the latter is designed to be tightened or released by torquing a nut.

In mechanical engineering, the thread angle of a screw is the included angle between the thread flanks, measured in a plane containing the thread axis. This is a defining factor for the shape of a screw thread. Standard values include:

The square thread form is a common screw thread profile, used in high load applications such as leadscrews and jackscrews. It gets its name from the square cross-section of the thread. It is the lowest friction and most efficient thread form, but it is difficult to fabricate.

A differential screw is a mechanism used for making small, precise adjustments to the spacing between two objects. A differential screw uses a spindle with two screw threads of differing leads, and possibly opposite handedness, on which two nuts move. As the spindle rotates, the space between the nuts changes based on the difference between the threads. These mechanisms allow extremely small adjustments using commonly available screws. A differential screw mechanism using two nuts incurs higher friction and therefore requires more torque to turn than a simple, single lead screw with an equivalent pitch.

The Swiss-designed Thury screw thread is a metric thread standard that was developed in the late nineteenth century for screws used in scientific and horological instruments. The thread is named after Marc Thury, an engineer and professor at the University of Geneva who contributed heavily to the standard's development.

The Löwenherz thread is a largely obsolete metric thread form designed in the late nineteenth century and frequently applied in precision instruments. It is named after Dr. Leopold Löwenherz, who was the director of the metrology institute Physikalisch-Technische Bundesanstalt in Berlin.