See also

| Wikimedia Commons has media related to Plywood . |

Laminate panel is a type of manufactured timber made from thin sheets of substrates or wood veneer. It is similar to the more widely used plywood, except that it has a plastic, protective layer on one or both sides. Laminate panels are used instead of plywood because of their resistance to impact, weather, moisture, shattering in cold (ductility), and chemicals.

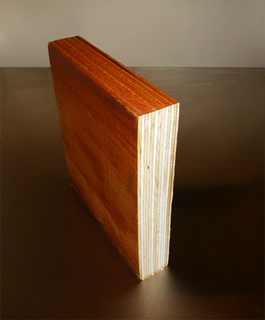

Laminate panel layers (called veneers) are glued together with adjacent plies having their grain at right angles to each other for greater strength. The plastic layer(s) added for protection vary in composition, thickness, color and texture according to the application.

A number of varieties of laminate panel exist for different applications.

The most commonly used thickness range from 3.2 mm (1⁄8 in) to 13 mm (1⁄2 in) and 9.5 mm (3⁄8 in), in a variety of colours and textures.

Laminate panels are used in many applications that need weather-proof, impact resistant sheet material. Typical end uses of spruce plywood are:

| Wikimedia Commons has media related to Plywood . |

Plywood is a material manufactured from thin layers or "plies" of wood veneer that are glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another. It is an engineered wood from the family of manufactured boards which include medium-density fibreboard (MDF), oriented strand board (OSB) and particle board (chipboard).

Flooring is the general term for a permanent covering of a floor, or for the work of installing such a floor covering. Floor covering is a term to generically describe any finish material applied over a floor structure to provide a walking surface. Both terms are used interchangeably but floor covering refers more to loose-laid materials.

Engineered wood, also called mass timber, composite wood, man-made wood, or manufactured board, includes a range of derivative wood products which are manufactured by binding or fixing the strands, particles, fibres, or veneers or boards of wood, together with adhesives, or other methods of fixation to form composite material. The panels vary in size but can range upwards of 64 by 8 feet and in the case of cross-laminated timber (CLT) can be of any thickness from a few inches to 16 inches (410 mm) or more. These products are engineered to precise design specifications, which are tested to meet national or international standards and provide uniformity and predictability in their structural performance. Engineered wood products are used in a variety of applications, from home construction to commercial buildings to industrial products. The products can be used for joists and beams that replace steel in many building projects. The term mass timber describes a group of building materials that can replace concrete assemblies. Broad-base adoption of mass timber and their substitution for steel and concrete in new mid-rise construction projects over the next couple decades has the potential of turning timber buildings into a global carbon sink, which could help mitigate climate change.

Oriented strand board (OSB) is a type of engineered wood similar to particle board, formed by adding adhesives and then compressing layers of wood strands (flakes) in specific orientations. It was invented by Armin Elmendorf in California in 1963. OSB may have a rough and variegated surface with the individual strips of around 2.5 cm × 15 cm, lying unevenly across each other, and is produced in a variety of types and thicknesses.

Medium-density fibreboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibres, often in a defibrator, combining it with wax and a resin binder, and forming it into panels by applying high temperature and pressure. MDF is generally more dense than plywood. It is made up of separated fibres, but can be used as a building material similar in application to plywood. It is stronger, and more dense, than particle board.

Boat building is the design and construction of boats and their systems. This includes at a minimum a hull, with propulsion, mechanical, navigation, safety and other systems as a craft requires.

Lamination is the technique/process of manufacturing a material in multiple layers, so that the composite material achieves improved strength, stability, sound insulation, appearance, or other properties from the use of the differing materials, such as plastic. A laminate is a permanently assembled object created using heat, pressure, welding, or adhesives. Various coating machines, machine presses and calendering equipment are used.

Glued laminated timber, also abbreviated glulam, is a type of structural engineered wood product constituted by layers of dimensional lumber bonded together with durable, moisture-resistant structural adhesives. In North America, the material providing the laminations is termed laminating stock or lamstock.

Particle board, also known as chipboard, is an engineered wood product manufactured from wood chips or jute-stick chips and a synthetic resin or other suitable binder, which is pressed and extruded. Particle board is often confused with oriented strand board, a different type of fiberboard that uses machined wood flakes and offers more strength.

Hardboard, also called high-density fiberboard (HDF), is a type of fiberboard, which is an engineered wood product. It is used in furniture and in the construction industry.

Laminated veneer lumber (LVL) is an engineered wood product that uses multiple layers of thin wood assembled with adhesives. It is typically used for headers, beams, rimboard, and edge-forming material. LVL offers several advantages over typical milled lumber: Made in a factory under controlled specifications, it is stronger, straighter, and more uniform. Due to its composite nature, it is much less likely than conventional lumber to warp, twist, bow, or shrink. LVL is a type of structural composite lumber, comparable to glued laminated timber (glulam) but with a higher allowable stress.

Kitchen cabinets are the built-in furniture installed in many kitchens for storage of food, cooking equipment, and often silverware and dishes for table service. Appliances such as refrigerators, dishwashers, and ovens are often integrated into kitchen cabinetry. There are many options for cabinets available at present.

In woodworking, veneer refers to thin slices of wood and sometimes bark, usually thinner than 3 mm, that typically are glued onto core panels to produce flat panels such as doors, tops and panels for cabinets, parquet floors and parts of furniture. They are also used in marquetry. Plywood consists of three or more layers of veneer. Normally, each is glued with its grain at right angles to adjacent layers for strength. Veneer beading is a thin layer of decorative edging placed around objects, such as jewelry boxes. Veneer is also used to replace decorative papers in Wood Veneer HPL. Veneer is also a type of manufactured board.

A countertop, also counter top, counter, benchtop, worktop or kitchen bench, is a firm, flat, horizontal surface built for work in kitchens or other food preparation areas, bathrooms or lavatories, and workrooms in general. The surface is frequently installed upon and supported by cabinets, positioned at an ergonomic height for the user and the particular task for which it is designed. A countertop may be constructed of various materials with different attributes of functionality, durability and aesthetics, and may have built-in appliances, or accessory items relative to the intended application.

Wood flooring is any product manufactured from timber that is designed for use as flooring, either structural or aesthetic. Wood is a common choice as a flooring material and can come in various styles, colors, cuts, and species. Bamboo flooring is often considered a form of wood flooring, although it is made from a grass (bamboo) rather than a timber.

Cross-laminated timber (CLT) is a wood panel product made from gluing together layers of solid-sawn lumber, i.e., lumber cut from a single log. Each layer of boards is usually oriented perpendicular to adjacent layers and glued on the wide faces of each board, usually in a symmetric way so that the outer layers have the same orientation. An odd number of layers is most common, but there are configurations with even numbers as well. Regular timber is an anisotropic material, meaning that the physical properties change depending on the direction at which the force is applied. By gluing layers of wood at right angles, the panel is able to achieve better structural rigidity in both directions. It is similar to plywood but with distinctively thicker laminations.

Vulcanized fibre or red fibre is a laminated plastic composed of only cellulose. The material is a tough, resilient, hornlike material that is lighter than aluminium, tougher than leather, and stiffer than most thermoplastics. The newer wood-laminating grade of vulcanized fibre is used to strengthen wood laminations used in skis, skateboards, support beams and as a sub-laminate under thin wood veneers.

Flexible stone veneer is a veneer with a layer of stone 1 to 5 mm thick. Flexible stone veneers should not be confused with traditional stone veneer. It is used for both interior and exterior and especially where bending to a curved surface is required. Flexible stone veneers are made from various types of slate, schist, or marble.

Molded plywood is the term for two- or three-dimensionally shaped products from multiple veneer layers that are glued together through heat and pressure in a pressing tool. The veneer layers are arranged crosswise at an angle of 90 degrees. Molded wood is used for flat furniture components such as seats, backrests and seat shells. When the veneer layers are arranged in the same direction, it is called laminated wood. It is used for armrests and chair frames. After pressing, the blanks are processed mechanically. A particular feature is the ability to produce different variations of shapes from the blanks. Due to its immense strength and low weight, molded wood is particularly suitable for interior decoration, seating furniture, bed slats, skateboards and vehicle construction.

Haskelite is the brand name of a plywood, once made by the Michigan-based Haskelite Manufacturing Corporation. It was made from waterproof glue developed by Henry L. Haskell. The moldable plywood was originally called Ser-O-Ply. It was used in the construction of various vehicles including military tanks, boats, airplanes, buses, trucks, and automobiles. The plywood was manufactured with different characteristics depending on particular needs and then given a brand name.