A clutch is a mechanical device that engages and disengages power transmission, especially from a drive shaft to a driven shaft. In the simplest application, clutches connect and disconnect two rotating shafts. In these devices, one shaft is typically attached to an engine or other power unit, while the other shaft provides output power for work. Typically the motions involved are rotary, but linear clutches also exist.

An axle or axletree is a central shaft for a rotating wheel or gear. On wheeled vehicles, the axle may be fixed to the wheels, rotating with them, or fixed to the vehicle, with the wheels rotating around the axle. In the former case, bearings or bushings are provided at the mounting points where the axle is supported. In the latter case, a bearing or bushing sits inside a central hole in the wheel to allow the wheel or gear to rotate around the axle. Sometimes, especially on bicycles, the latter type axle is referred to as a spindle.

A differential is a gear train with three drive shafts that has the property that the rotational speed of one shaft is the average of the speeds of the others, or a fixed multiple of that average.

Four-wheel drive, also called 4×4 or 4WD, refers to a two-axled vehicle drivetrain capable of providing torque to all of its wheels simultaneously. It may be full-time or on-demand, and is typically linked via a transfer case providing an additional output drive shaft and, in many instances, additional gear ranges.

Propulsion transmission is the mode of transmitting and controlling propulsion power of a machine. The term transmission properly refers to the whole drivetrain, including clutch, gearbox, prop shaft, differential, and final drive shafts. In the United States the term is sometimes used in casual speech to refer more specifically to the gearbox alone, and detailed usage differs. The transmission reduces the higher engine speed to the slower wheel speed, increasing torque in the process. Transmissions are also used on pedal bicycles, fixed machines, and where different rotational speeds and torques are adapted.

In mechanical or automotive engineering, a freewheel or overrunning clutch is a device in a transmission that disengages the driveshaft from the driven shaft when the driven shaft rotates faster than the driveshaft. An overdrive is sometimes mistakenly called a freewheel, but is otherwise unrelated.

quattro is the trademark used by the automotive brand Audi to indicate that all-wheel drive (AWD) technologies or systems are used on specific models of its automobiles.

A transfer case is a part of the drivetrain of four-wheel-drive, all-wheel-drive, and other multiple powered axle vehicles. The transfer case transfers power from the transmission to the front and rear axles by means of drive shafts. It also synchronizes the difference between the rotation of the front and rear wheels, and may contain one or more sets of low range gears for off-road use.

A locking differential is a mechanical component, commonly used in vehicles, designed to overcome the chief limitation of a standard open differential by essentially "locking" both wheels on an axle together as if on a common shaft. This forces both wheels to turn in unison, regardless of the traction available to either wheel individually.

A drive shaft, driveshaft, driving shaft, tailshaft, propeller shaft, or Cardan shaft is a component for transmitting mechanical power and torque and rotation, usually used to connect other components of a drivetrain that cannot be connected directly because of distance or the need to allow for relative movement between them.

ATTESA is a four-wheel drive system used in some automobiles produced by the Japanese automaker Nissan, including some models under its luxury marque Infiniti.

Jeep uses a variety of four-wheel drive systems on their vehicles. These range from basic part-time systems that require the driver to move a control lever to send power to four wheels, to permanent four-wheel systems that monitor and sense traction needs at all four wheels automatically under all conditions.

Super Select is the brand name of a four-wheel drive system produced by Mitsubishi Motors, used worldwide except for North America, where it was initially known as Active-Trac. It was first introduced in 1991 with the then-new second generation of the Mitsubishi Pajero.

ControlTrac four-wheel drive is the brand name of a selectable automatic full-time four-wheel drive system offered by Ford Motor Company. The four-wheel drive system was designed and developed at BorgWarner under its TorqTransfer Systems division in the mid 1980s. BorgWarner calls the system Torque-On-Demand (TOD). ControlTrac was the first automatic system to use software control and no planetary or bevel geared center differential. Instead of a planetary or bevel geared center differential, the system uses a variable intelligent locking center multi-disc differential.

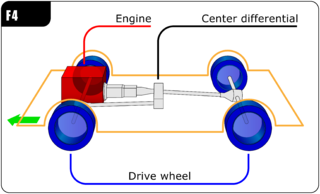

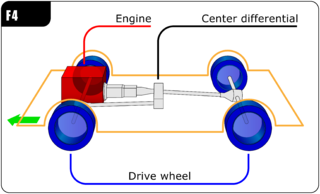

In automotive design, an F4, or front-engine, four-wheel drive (4WD) layout places the internal combustion engine at the front of the vehicle and drives all four roadwheels. This layout is typically chosen for better control on many surfaces, and is an important part of rally racing, as well as off-road driving. In terms of racing purposes, whether it be on-road or off-road, can be described as follows,

A team that pursues the Weak LS4WD architecture will minimize the development cost of the front-wheel drive system at the expense of having a larger rear powertrain. The Weak architecture produces a vehicle with a large powersplit between the front and rear powertrains, while the Strong architecture recommends a vehicle with more similar power and torque requirements for the front and rear.

A center axle disconnect system or CAD is an alternative to locking hubs. CAD systems are typically used in front drive axles on four wheel drive vehicles. A CAD system works by having an axle shaft split into two pieces. One piece is connected to the carrier, the other connected to the wheel. This reduces drag on the axle by allowing only the spider and side gears to spin, while the differential carrier, pinion and drive shaft are at rest. The axle is engaged by connecting the two split axle shafts. The ends of the axles are typically splined and use a collar to connect the two shafts together by sliding over both shafts.

Driveline windup is also known as "axle binding" or "driveline binding".

A drivetrain is the group of components that deliver mechanical power from the prime mover to the driven components. In automotive engineering, the drivetrain is the components of a motor vehicle that deliver power to the drive wheels. This excludes the engine or motor that generates the power. In marine applications, the drive shaft will drive a propeller, thruster, or waterjet rather than a drive axle, while the actual engine might be similar to an automotive engine. Other machinery, equipment and vehicles may also use a drivetrain to deliver power from the engine(s) to the driven components.

An all-wheel drive vehicle is one with a powertrain capable of providing power to all its wheels, whether full-time or on-demand.

This glossary of automotive terms is a list of definitions of terms and concepts related to automobiles, including their parts, operation, and manufacture, as well as automotive engineering, auto repair, and the automotive industry in general. For more specific terminology regarding the design and classification of various automobile styles, see Glossary of automotive design; for terms related to transportation by road, see Glossary of road transport terms; for competitive auto racing, see Glossary of motorsport terms.