Related Research Articles

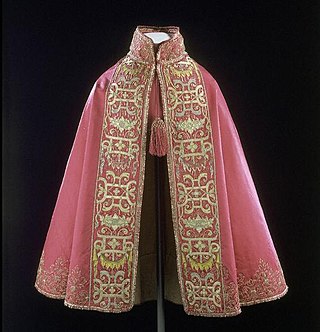

Textile is an umbrella term that includes various fiber-based materials, including fibers, yarns, filaments, threads, different fabric types, etc. At first, the word "textiles" only referred to woven fabrics. However, weaving is not the only manufacturing method, and many other methods were later developed to form textile structures based on their intended use. Knitting and non-woven are other popular types of fabric manufacturing. In the contemporary world, textiles satisfy the material needs for versatile applications, from simple daily clothing to bulletproof jackets, spacesuits, and doctor's gowns.

Yarn is a long continuous length of interlocked fibres, used in sewing, crocheting, knitting, weaving, embroidery, ropemaking, and the production of textiles. Thread is a type of yarn intended for sewing by hand or machine. Modern manufactured sewing threads may be finished with wax or other lubricants to withstand the stresses involved in sewing. Embroidery threads are yarns specifically designed for needlework. Yarn can be made of a number of natural or synthetic materials, and comes in a variety of colors and thicknesses. Although yarn may be dyed different colours, most yarns are solid coloured with a uniform hue.

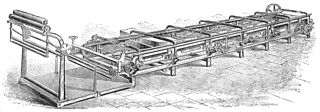

Calendering of textiles is a finishing process used to smooth, coat, or thin a material. With textiles, fabric is passed between calender rollers at high temperatures and pressures. Calendering is used on fabrics such as moire to produce its watered effect and also on cambric and some types of sateens.

Dyeing is the application of dyes or pigments on textile materials such as fibers, yarns, and fabrics with the goal of achieving color with desired color fastness. Dyeing is normally done in a special solution containing dyes and particular chemical material. Dye molecules are fixed to the fiber by absorption, diffusion, or bonding with temperature and time being key controlling factors. The bond between dye molecule and fiber may be strong or weak, depending on the dye used. Dyeing and printing are different applications; in printing, color is applied to a localized area with desired patterns. In dyeing, it is applied to the entire textile.

Ninon is a lightweight, sheer fabric made with plain or leno weaving, it is a suitable material for curtains, evening wear and lingerie. Ninon is made with variety of filament yarns such as polyester, silk, rayon or nylon.

Sanforization is a treatment for fabrics to reduce shrinkage from washing. The process was patented by Sanford Lockwood Cluett (1874–1968) in 1930. It works by stretching, shrinking and fixing the woven cloth in both length and width before cutting and producing, to reduce the shrinkage which would otherwise occur after washing. The original patent mentioned "goods of cotton, linen, woolen, silk, rayon, and combinations thereof".

A staple fiber is a textile fiber of discrete length. The opposite is a filament fiber, which comes in continuous lengths. Staple length is a characteristic fiber length of a sample of staple fibers. A fiber is made up of natural substances and is known for being longer than it is wide. It is an essential criterion in yarn spinning, and aids in cohesion and twisting. Compared to synthetic fibers, natural fibers tend to have different and shorter lengths. The quality of natural fibers like cotton is categorized on staple length such as short, medium, long staple, and extra-long. Gossypium barbadense, one of several cotton species, produces extra-long staple fibers. The staple fibers may be obtained from natural and synthetic sources. In the case of synthetics and blends, the filament yarns are cut to a predetermined length.

In textile manufacturing, finishing refers to the processes that convert the woven or knitted cloth into a usable material and more specifically to any process performed after dyeing the yarn or fabric to improve the look, performance, or "hand" (feel) of the finish textile or clothing. The precise meaning depends on context.

Dimensional stability pertains to a fabric's ability to maintain its initial size and shape even after undergoing wear and care, which is a desirable property. Dimension stability in fabrics or Shrinkage is the change of dimensions in textile products when they are washed or relaxed. The change is always expressed relative to the dimensions before the exposure of washing or relaxing. Shrinkage is also called residual shrinkage and measured in percentage. The major cause of shrinkages is the release of stresses and strains introduced in manufacturing processes. Textile manufacturing is based on the conversion of fiber into yarn, yarn into fabric, includes spinning, weaving, or knitting, etc. The fabric passes through many inevitable changes and mechanical forces during this journey. When the products are immersed in water, the water acts as a relaxing medium, and all stresses and strains are relaxed and the fabric tries to come back to its original state.

A stenter is a specialist oven used in the textile industry for drying and heat treating fabric after wet processing.

Swanskin is a close woven twill-weave flannel cloth for work clothes. It was used by fishermen and laborers. It is employed also as Ironing cloth to support on ironing tables.

Fabric inspection, also known as fabric checking, is a systematic fabric evaluation in which defects are identified. Fabric inspection helps understand quality in terms of color, density, weight, printing, measurement, and other quality criteria prior to garment production. Fabric inspection takes place at various stages of manufacturing, including intermediate and final. "Perching" was another term for fabric inspection.

Hand feel is the property of fabrics related to the touch that expresses sensory comfort. It refers to the way fabrics feel against the skin or in the hand and conveys information about the cloth's softness and smoothness. Hand feel is an estimated and subjective property of different fabrics, but nowadays, hand feel could be measured and assessed statistically.

Textile performance, also known as fitness for purpose, is a textile's capacity to withstand various conditions, environments, and hazards, qualifying it for particular uses. The performance of textile products influences their appearance, comfort, durability, and protection. Different textile applications require a different set of performance parameters. As a result, the specifications determine the level of performance of a textile product. Textile testing certifies the product's conformity to buying specification. It describes product manufactured for non-aesthetic purposes, where fitness for purpose is the primary criterion. Engineering of high-performance fabrics presents a unique set of challenges.

Chemical finishing of textiles refers to the process of applying and treating textiles with a variety of chemicals in order to achieve desired functional and aesthetic properties. Chemical finishing of textiles is a part of the textile finishing process where the emphasis is on chemical substances instead of mechanical finishing. Chemical finishing in textiles also known as wet finishing. Chemical finishing adds properties to the treated textiles. Softening of textiles, durable water repellancy and wrinkle free fabric finishes are examples of chemical finishing.

Compaction (compacting) is a finishing process used to minimize shrinking in textiles. Textile products that are loosely woven or knitted shrink more, whereas tightly knitted and woven products are more stable. The structure of knitted fabrics is competitively loose and flexible. Compaction, like sanforization for woven fabric, is intended to reduce shrinkage in tube and open width Knitted textiles.

Aesthetics in textiles is one of the basic concepts of serviceability of textiles. It is determined by the perception of touch and sight. Aesthetics imply the appearance and attraction of textile products; it includes the color and texture of the material. It is a statement about the end user (consumer) and the target market. When combined with fabric construction, the finish of the clothing material, garment fit, style, and fashion compatibility, colours create an aesthetic comfort. All of these elements work together to satisfy our visual perception. Aesthetics incorporates the role of evaluation also.

Shearing is a kind of mechanical finish in which the appearance of the fabric is enhanced by cutting the loops or raised surface to a uniform and even height. The machine may have a spiral blade similar to a grass cutting machine. A Shearing machine can cut the loop or the pile to a desired level. Shearing was most commonly used to make woolens and worsted materials. It was a part of dry finishing of woolen and worsted goods. Previously, shearing was also a component of gigging or napping; when partially produced goods were exposed to shear in order to improve the impact of gigging or napping, the process was referred to as "cropping."

Product development in the context of textiles means developing and manufacturing new products that meet the requirements of serviceability as per user and target market while taking care of timelines, sell-ability, and profitability. It could be a new product altogether or an improvement or modification to an existing company's or a competitor's product. Product development involves many experts with specialist skills, from identifying product attributes to knowing how to make the product to fulfil consumer expectations.

Textile testing is the process of measuring the properties and performance of textile materials—textile testing includes physical and chemical testing of raw materials to finished products.

References

- 1 2 3 4 5 Kadolph, Sara J. (2007). Textiles. Upper Saddle River, N.J. : Pearson Prentice Hall. pp. 363–364. ISBN 978-0-13-118769-6 – via Internet Archive.

- ↑ Evans, Mary (1939). A guide to textiles. New York, J. Wiley & Sons, Inc.; London, Chapman & Hall, Limited. p. 60 – via Internet Archive.

- 1 2 3 4 Miscellaneous Series. U.S. Government Printing Office. 1916. p. 264.

- ↑ American Fabrics Magazine (1960). AF encyclopedia of textiles. Englewood Cliffs, N.J., Prentice-Hall. p. 113 – via Internet Archive.

- ↑ Fairchild's dictionary of textiles. New York, Fairchild Publications. 1959. p. 327 – via Internet Archive.

- ↑ Lampe, Clotilde; Yurick, Clotilde (2004). Clotilde's Sew Smart. DRG Wholesale. pp. 1–6. ISBN 978-0-9748217-0-2.

- ↑ Stauffer, Jeanne (2004). Sewing Smart with Fabric. DRG Wholesale. p. 89. ISBN 978-1-59217-018-0.

- ↑ Picken, Mary Brooks (1999). A dictionary of costume and fashion: historic and modern: with over 950 illustrations. Mineola, NY: Dover Publications. p. 263. ISBN 978-0-486-40294-9 – via Internet Archive.

- ↑ Panda, H. (2010-10-05). The Complete Book on Textile Processing and Silk Reeling Technology. Asia Pacific Business Press. p. 84. ISBN 978-81-7833-135-5.

- ↑ Choudhury, Asim Kumar Roy (2017-04-29). Principles of Textile Finishing. Woodhead Publishing. p. 48. ISBN 978-0-08-100661-0.

- 1 2 3 The Clothier and Furnisher. 1903. p. 56.

- ↑ America's Textile Reporter: For the Combined Textile Industries. 1905.

- ↑ Linton, George Edward (1966). Applied basic textiles; raw material, construction, color, and finish, fabric analysis, chemical and physical testing of textiles, spot and stain removal, and care of clothing. New York: Duell, Sloan and Pearce. p. 235 – via Internet Archive.

- ↑ America's Textile Reporter: For the Combined Textile Industries. 1905.