Lowell National Historical Park is a National Historical Park of the United States located in Lowell, Massachusetts. Established in 1978 a few years after Lowell Heritage State Park, it is operated by the National Park Service and comprises a group of different sites in and around the city of Lowell related to the era of textile manufacturing in the city during the Industrial Revolution. In 2019, the park is scheduled to be included as Massachusetts' representative in the America the Beautiful Quarters series.

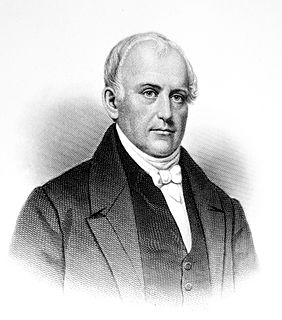

Francis Cabot Lowell was an American businessman for whom the city of Lowell, Massachusetts, is named. He was instrumental in bringing the Industrial Revolution to the United States.

The Lawrence textile strike, also known as the Bread and Roses strike, was a strike of immigrant workers in Lawrence, Massachusetts, in 1912 led by the Industrial Workers of the World (IWW). Prompted by a two-hour pay cut corresponding to a new law shortening the workweek for women, the strike spread rapidly through the town, growing to more than twenty thousand workers and involving nearly every mill in Lawrence. Starting January 1, 1912, the Massachusetts government started to enforce a law that allowed women to work a maximum of 54 hours, rather than 56 hours. Ten days later, they found out that pay had been reduced along with the cut in hours.

Paul Moody was a U.S. textile machinery inventor born in Byfield, Massachusetts. He is often credited with developing and perfecting the first power loom in America, which launched the first successful integrated cotton mill at Waltham, Massachusetts in 1814, under the leadership of Francis Cabot Lowell and his associates.

The Boston Associates were a loosely linked group of investors in 19th-century New England. They included Nathan Appleton, Patrick Tracy Jackson, Abbott Lawrence, and Amos Lawrence. Often related directly or through marriage, they were based in Boston, Massachusetts. The term "Boston Associates" was coined by historian Vera Shlakmen in 1935.

Completed in 1796, the Pawtucket Canal was originally built as a transportation canal to circumvent the Pawtucket Falls of the Merrimack River in East Chelmsford, Massachusetts. In the early 1820s it became a major component of the Lowell power canal system. with the founding of the textile industry at what became Lowell.

The factory system is a method of manufacturing using machinery and division of labour. Because of the high capital cost of machinery and factory buildings, factories were typically privately owned by wealthy individuals who employed the operative labour. Use of machinery with the division of labour reduced the required skill level of workers and also increased the output per worker.

The Waltham-Lowell system was a labor and production model employed during the rise of the American textile industry in the United States, particularly in New England, amid the larger backdrop of rapid expansion of the Industrial Revolution the early 19th century.

In labor disputes, a walkout is a labor strike, the act of employees collectively leaving the workplace as an act of protest.

The Lowell Offering was a monthly periodical collected contributed works of poetry and non-fiction by the female textile workers of the Lowell, Massachusetts textile mills of the early American industrial revolution. It began in 1840 and lasted until 1845.

Patrick Tracy Jackson was a United States manufacturer, one of the founders of the Boston Manufacturing Company of Waltham, Massachusetts, and later a founder of the Merrimack Manufacturing Company, whose developments formed the nucleus of Lowell, Massachusetts.

The Amoskeag Manufacturing Company was a textile manufacturer which founded Manchester, New Hampshire. From modest beginnings in near wilderness, it grew throughout the 19th century into the largest cotton textile plant in the world. At its peak, Amoskeag was unrivaled both for the quality and quantity of its products. But with great size came an inability to adapt. In the early 20th century, the business failed to adapt to changing economic and social conditions.

The Lowell Mill Girls were young female workers who came to work in industrial corporations in Lowell, Massachusetts, during the Industrial Revolution in the United States. The workers initially recruited by the corporations were daughters of propertied New England farmers, typically between the ages of 15 and 35. By 1840, the height of the Industrial Revolution, the textile mills had recruited over 8,000 women, who came to make up nearly three-quarters of the mill workforce, at a very slow rate, most were forced to work faster than they could.

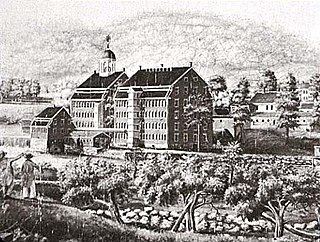

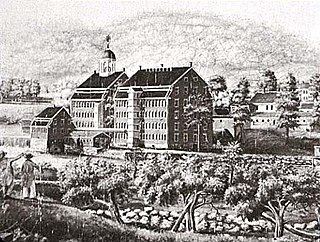

The History of Lowell is closely tied to its location along the Pawtucket Falls of the Merrimack River, from being an important fishing ground for the Pennacook tribe to providing water power for the factories that formed the basis of the city's economy for a century. The city of Lowell was started in the 1820s as a money-making venture and social project referred to as "The Lowell Experiment", and quickly became the United States' largest textile center. However, within approximately a century, the decline and collapse of that industry in New England placed the city into a deep recession. Lowell's "rebirth", partially tied to Lowell National Historical Park, has made it a model for other former industrial towns, although the city continues to struggle with deindustrialization and suburbanization.

Sarah George Bagley was a labor leader in New England during the 1840s; an advocate of shorter workdays for factory operatives and mechanics, she campaigned to make ten hours of labor per day the maximum in Massachusetts.

Charles River Museum of Industry & Innovation is a museum of the American Industrial Revolution located on the Charles River Bike Path, near the intersection of the Charles River and Moody Street in Waltham, Massachusetts. It houses and displays machinery and artifacts of the industrial revolution from the nineteenth and twentieth centuries. The building was originally built as part of the Boston Manufacturing Company, Francis Cabot Lowell's seminal, fully integrated textile mill. The museum, which was incorporated in 1980 and opened to the public in 1988, takes up only a small portion of the previous mill building complex.

The Voice of Industry was a worker-run newspaper published between 1845–1848, at the height of the American Industrial Revolution. The Voice was centrally concerned with the dramatic social changes wrought by the Industrial Revolution, as workers came to depend on corporations for a wage.