Related Research Articles

Type 72 Non-Metallic is a Chinese circular, plastic bodied landmine which is designed to damage or destroy a vehicle by blast effect.

The RP-3 was a British air to ground rocket projectile introduced during the Second World War. The "3 inch" designation referred to the nominal diameter of the rocket motor tube. The use of a 60-pound (27 kg) warhead gave rise to the alternative name of the "60-pound rocket". Though primarily an air-to-ground weapon, it saw limited use in other roles. They were generally used by British fighter-bomber aircraft against targets such as tanks, trains, motor transport and buildings, as well as by Coastal Command and Royal Navy aircraft against U-boats and ships.

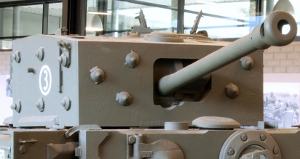

The Ordnance QF 75 mm, abbreviated to OQF 75 mm, was a British tank gun of the Second World War. It was obtained by boring out the Ordnance QF 6-pounder 57 mm anti-tank gun to 75 mm, to give better performance against infantry targets in a similar fashion to the 75 mm M3 gun fitted to the American Sherman tank. The QF came from "quick-firing", referring to the use of ammunition where the shell has a fixed cartridge. The gun was also sometimes known as ROQF from Royal Ordnance Quick-Firing.

The Tellermine 42 (T.Mi.42) was a German metal-cased anti-tank blast mine used during the Second World War. The mine was a development of the Tellermine 35 with improved resistance to blast. It was followed by the simplified Tellermine 43.

The Tellermine 43 was a German circular steel cased anti-tank blast mine used during the Second World War. It was a simplified version of the Tellermine 42, which enabled simpler production techniques. Between March 1943 and the end of World War II, over 3.6 million Tellermine 43s were produced by Germany. Copies of the mine were produced by several countries including Denmark (M/47), France and Yugoslavia (TMM-1).

The PMN series of blast anti-personnel mines were designed and manufactured in the Soviet Union. They are one of the most widely used and commonly found devices during demining operations. They are sometimes nicknamed "black widow" because of their dark casings.

The M15 mine is a large circular United States anti-tank blast mine, first deployed during the Korean War. Essentially, it is a larger version of the M6A2 anti-tank mine, which it replaced. Although the M15 has been superseded by the M19 mine, the U.S. retains large stocks of M15s because they are still regarded as reliable and effective weapons. When used against main battle tanks the M15 is primarily a "track-breaker" which creates mobility kills, but has a comparatively small likelihood of causing crew fatalities. However, when used against lighter vehicles such as APCs or unarmored vehicles such as trucks the damage inflicted is much more severe.

The VS-50 is a circular plastic cased anti-personnel blast mine that entered production in 1985, formerly manufactured by the now-defunct Valsella Meccanotecnica SpA, an Italian high-tech defence industry specialized in area denial systems which was also the manufacturer of the Valmara 69 and one of the first industries in the world to implement plastic construction for landmines. The design is similar to the TS-50 and VS-MK2 mine. It is blast resistant and can be used in a minimum metal configuration. Though unlikely to kill, the explosive charge contained within a VS-50 is quite sufficient to destroy the victim's foot: the blast is capable of penetrating 5 mm of mild steel leaving an 80 mm-diameter hole.

The TM-62 is a Soviet anti-tank blast mine made in many variants. It has a central fuze and typically a 7.5 kilograms (17 lb) explosive charge, but the variants vary greatly in detail. The mine can be laid manually or automatically from a mine laying machine including the PMR-1, PMR-2 wheeled towed mine layers, the GMZ tracked mine laying vehicle and the VMR-2 helicopter mine laying system. The TM-62 can be fitted with the same fuzes as the TM-72, which include MVN-72 and MVN-80 fuzes which are vibration and magnetism sensitive.

The M1, M1A1 and M4 are circular steel cased United States anti-tank blast mines with a distinctive cross shaped pressure spider. The mine was used during the Second World War and a copy produced in Argentina was used during the Falklands War. Another copy is produced in China. designated the No. 4 mine. Variants of the mine have also been deployed in Chad and Tunisia.

The Mk 7 mine was a circular British anti-tank blast mine. It replaced the World War 2-era Mk 5 mine, and has in turn been replaced by the L9 bar mine.

The TMA-4 is a circular plastic cased Yugoslavian minimum metal anti-tank blast mine. It is a modernized version of the TMA-3. The mine is basically a cast block of TNT with three fuze wells cut into it, encased in plastic. Three black plastic UTMA-4 fuzes are installed into the top surface of the mine. A thin rope carry handle is also provided. The small pressure plate area of the fuzes make the mine resistant to overpressure from explosive demining techniques. Additionally the low metal content of the mine make it very difficult to detect. Although no secondary fuze well is provided, it is possible that the mine could be fitted with improvised anti-handling devices.

The TMM-1 is a circular, metal-cased, Yugoslavian anti-tank blast mine. It is a direct copy of the German Tellermine 43. The mine has a central fuze well that is covered by a screw on pressure plate. Two secondary fuze well are fitted to the side and bottom of the mine allowing the installation of anti-handling devices. The mine is found in Bosnia, Croatia, and Serbia.

The TM 65 is a circular Finnish minimum metal anti-tank blast mine. It is broadly based on the Russian TM-62 mine. The mines body is made from a thin shell of fibreglass over a cast block of explosive, with a central fuze well that holds the pressure fuze. The original TM 65 used a US-65 fuze as used in the SM-65 anti-personnel mine, the later TM 65 77 uses a pressure fuze similar to the Russian MV-5 fuze called Painesytytin 77.

The FMK-1 is a small circular Argentina anti-personnel blast mine which, when fitted with a stiffened pressure plate, is also used as the fuze for the FMK-3 and FMK-5 anti-tank mines. The mine has a circular plastic body, with a number of small ribs running vertically around the outside of the mine, with the circular detonator and striker protruding on each side. The pressure plate has a distinctive six pointed star shape ribbing for stiffness. The bottom of the mine has small base plug inside which a small stud is installed. The stud increases the activation pressure of the mine. A metal detector disc can be added to the bottom of the mine, but it is not often used. It is actually in service with the Argentine Army.

The Teller mine was a German-made antitank mine common in World War II. With explosives sealed inside a sheet metal casing and fitted with a pressure-actuated fuze, Teller mines had a built-in carrying handle on the side. As the name suggests the mines were plate-shaped.

The Anti-Tank Mine General Service Mark II was a British anti-tank blast mine used during the Second World War. It consisted of a body about 7.5 in (190 mm) in diameter and 3.25 in (83 mm). The mine has a central fuze well accessed from the bottom, with a main charge in a cavity around the well consisting of about 4 lb (1.8 kg) of TNT. The mine is fitted with a thin brass cover, which acts as a pressure plate. The cover is suspended over the main body of the main by four leaf springs. A Sorbo ring can be fitted between the cover and the mine body, which absorbs shock and blast and allows the mines to be planted as close as two feet (0.61 m) without causing sympathetic detonation.

The M1936 (Mle1936) is a French light anti-tank mine used during the Second World War. The mine was captured in large numbers by the German army after the Fall of France, and was later used in the Atlantikwall, North Africa and Italy. The mine consists of a base plate on top of which is a rectangular steel box containing an explosive charge. On top of the container are two M1935 or M1936 pressure fuzes. A pressure cover is fixed on top of the container by wires attached at either end of the container. Two pressure bars are welded to the inside of the pressure cover, each one is directly over a fuze—however, each bar has a recess preventing it from pressing on the pressure fuze, until a safety bar is inserted. The safety bar covers the recesses allowing the pressure cover to bear down directly on the pressure fuzes.

The Pignone mod.43 were bakelite cased Italian anti-tank blast mines used during the Second World War in North Africa and Italy.

The TMRP-6 is a former Yugoslavian anti tank EFP mine.

References

- ↑ Green, Constance M.; Thomson, Harry C.; Roots, Peter C. (1955). United States Army in World War II, The Technical Services, The Ordnance Department: Planning Munitions for War. Washington, D.C.: Office of the Chief of Military History, United States Army. pp. 384–387.