Micromachining may refer to:

The technique for fabrication of 3D and 2D structures on the micrometer scale.

ISO 216 is an international standard for paper sizes, used around the world except in North America and parts of Latin America. The standard defines the "A", "B" and "C" series of paper sizes, including A4, the most commonly available paper size worldwide. Two supplementary standards, ISO 217 and ISO 269, define related paper sizes; the ISO 269 "C" series is commonly listed alongside the A and B sizes.

MEMS is the technology of microscopic devices incorporating both electronic and moving parts. MEMS are made up of components between 1 and 100 micrometres in size, and MEMS devices generally range in size from 20 micrometres to a millimetre, although components arranged in arrays can be more than 1000 mm2. They usually consist of a central unit that processes data and several components that interact with the surroundings.

In aeronautics, the chord is an imaginary straight line joining the leading edge and trailing edge of an aerofoil. The chord length is the distance between the trailing edge and the point where the chord intersects the leading edge. The point on the leading edge used to define the chord may be the surface point of minimum radius. For a turbine aerofoil the chord may be defined by the line between points where the front and rear of a 2-dimensional blade section would touch a flat surface when laid convex-side up.

Vaporization of an element or compound is a phase transition from the liquid phase to vapor. There are two types of vaporization: evaporation and boiling. Evaporation is a surface phenomenon, whereas boiling is a bulk phenomenon.

A leading-edge extension (LEX) is a small extension to an aircraft wing surface, forward of the leading edge. The primary reason for adding an extension is to improve the airflow at high angles of attack and low airspeeds, to improve handling and delay the stall. A dog tooth can also improve airflow and reduce drag at higher speeds.

In aeronautics, the aspect ratio of a wing is the ratio of its span to its mean chord. It is equal to the square of the wingspan divided by the wing area. Thus, a long, narrow wing has a high aspect ratio, whereas a short, wide wing has a low aspect ratio.

In aerodynamics, the lift-to-drag ratio is the lift generated by an aerodynamic body such as an aerofoil or aircraft, divided by the aerodynamic drag caused by moving through air. It describes the aerodynamic efficiency under given flight conditions. The L/D ratio for any given body will vary according to these flight conditions.

In aerodynamics, lift-induced drag, induced drag, vortex drag, or sometimes drag due to lift, is an aerodynamic drag force that occurs whenever a moving object redirects the airflow coming at it. This drag force occurs in airplanes due to wings or a lifting body redirecting air to cause lift and also in cars with airfoil wings that redirect air to cause a downforce. It is symbolized as , and the lift-induced drag coefficient as .

Micromachines are mechanical objects that are fabricated in the same general manner as integrated circuits. They are generally considered to be between 100 nanometres to 100 micrometres in size, though that is debatable. The applications of micromachines include accelerometers that detect when a car has hit an object and trigger an airbag. Complex systems of gears and levers are another application.

Dry etching refers to the removal of material, typically a masked pattern of semiconductor material, by exposing the material to a bombardment of ions that dislodge portions of the material from the exposed surface. A common type of dry etching is reactive-ion etching. Unlike with many of the wet chemical etchants used in wet etching, the dry etching process typically etches directionally or anisotropically.

Surface micromachining builds microstructures by deposition and etching structural layers over a substrate. This is different from Bulk micromachining, in which a silicon substrate wafer is selectively etched to produce structures.

Bulk micromachining is a process used to produce micromachinery or microelectromechanical systems (MEMS).

Microfabrication is the process of fabricating miniature structures of micrometre scales and smaller. Historically, the earliest microfabrication processes were used for integrated circuit fabrication, also known as "semiconductor manufacturing" or "semiconductor device fabrication". In the last two decades microelectromechanical systems (MEMS), microsystems, micromachines and their subfields, microfluidics/lab-on-a-chip, optical MEMS, RF MEMS, PowerMEMS, BioMEMS and their extension into nanoscale have re-used, adapted or extended microfabrication methods. Flat-panel displays and solar cells are also using similar techniques.

In nanotechnology, nanorods are one morphology of nanoscale objects. Each of their dimensions range from 1–100 nm. They may be synthesized from metals or semiconducting materials. Standard aspect ratios are 3-5. Nanorods are produced by direct chemical synthesis. A combination of ligands act as shape control agents and bond to different facets of the nanorod with different strengths. This allows different faces of the nanorod to grow at different rates, producing an elongated object.

Micropumps are devices that can control and manipulate small fluid volumes. Although any kind of small pump is often referred to as micropump, a more accurate definition restricts this term to pumps with functional dimensions in the micrometer range. Such pumps are of special interest in microfluidic research, and have become available for industrial product integration in recent years. Their miniaturized overall size, potential cost and improved dosing accuracy compared to existing miniature pumps fuel the growing interest for this innovative kind of pump.

HARMST is an acronym for high aspect ratio microstructure technology, which describes fabrication technologies, used to create high-aspect-ratio microstructures with heights between tens of micrometers up to a centimeter, and aspect ratios greater than 10:1. Examples include the LIGA fabrication process, advanced silicon etch, and deep reactive ion etching.

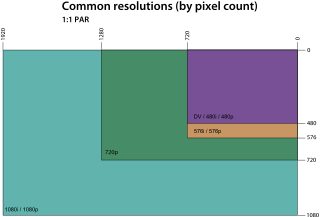

The graphics display resolution is the width and height dimension of an electronic visual display device, measured in pixels. This information is used for electronic devices such as a computer monitor. Certain combinations of width and height are standardized and typically given a name and an initialism which is descriptive of its dimensions. A graphics display resolution can be used in tandem with the size of the graphics display to calculate pixel density. An increase in the pixel density often correlates with a decrease in the size of individual pixels on a display.

The aspect ratio of an image is the ratio of its width to its height, and is expressed with two numbers separated by a colon, such as 16:9, sixteen-to-nine. For the x:y aspect ratio, the image is x units wide and y units high. Common aspect ratios are 1.85:1 and 2.39:1 in cinematography, 4:3 and 16:9 in television photography, and 3:2 in still photography.

Foturan is a photosensitive glass by SCHOTT Corporation developed in 1984. It is a technical glass-ceramic which can be structured without photoresist when it is exposed to shortwave radiation such as ultraviolet light and subsequently etched.

ABS-CBN HD was a Philippine pay television channel, working as the high-definition feed of ABS-CBN. It was launched on October 3, 2015 initially on Sky Cable and Destiny Cable and later on iWant, Sky On Demand, and Sky Direct, broadcasting in 1080i at a frame rate of 50 fps or at 60fps. The network including its HD feed dissolved on May 5, 2020 at 7:52 pm following TV Patrol. It was replaced by Kapamilya Channel HD on June 13, 2020.