Pressure is the force applied perpendicular to the surface of an object per unit area over which that force is distributed. Gauge pressure is the pressure relative to the ambient pressure.

Relative density, or specific gravity, is the ratio of the density of a substance to the density of a given reference material. Specific gravity usually means relative density with respect to water. The term "relative density" is often preferred in scientific usage. It is defined as a ratio of density of particular substance with that of water.

A non-Newtonian fluid is a fluid that does not follow Newton's law of viscosity, i.e. constant viscosity independent of stress. In non-Newtonian fluids, viscosity can change when under force to either more liquid or more solid. Ketchup, for example, becomes runnier when shaken and is thus a non-Newtonian fluid. Many salt solutions and molten polymers are non-Newtonian fluids, as are many commonly found substances such as custard, honey, toothpaste, starch suspensions, corn starch, paint, blood, and shampoo.

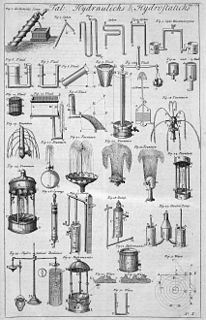

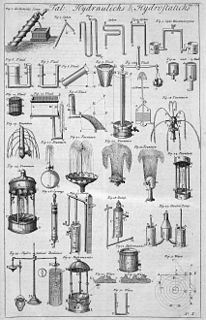

A hydrometer is an instrument used for measuring the relative density of liquids based on the concept of buoyancy. They are typically calibrated and graduated with one or more scales such as specific gravity.

Flow measurement is the quantification of bulk fluid movement. Flow can be measured in a variety of ways. The common types of flowmeters that find industrial application can be listed as below:

The word siphon is used to refer to a wide variety of devices that involve the flow of liquids through tubes. In a narrower sense, the word refers particularly to a tube in an inverted 'U' shape, which causes a liquid to flow upward, above the surface of a reservoir, with no pump, but powered by the fall of the liquid as it flows down the tube under the pull of gravity, then discharging at a level lower than the surface of the reservoir from which it came.

Fluid statics or hydrostatics is the branch of fluid mechanics that studies "fluids at rest and the pressure in a fluid or exerted by a fluid on an immersed body".

A mud engineer works on an oil well or gas well drilling rig, and is responsible ensuring the properties of the drilling fluid, also known as drilling mud, are within designed specifications.

A fluidised bed is a physical phenomenon occurring when a quantity of a solid particulate substance is placed under appropriate conditions to cause a solid/fluid mixture to behave as a fluid. This is usually achieved by the introduction of pressurized fluid through the particulate medium. This results in the medium then having many properties and characteristics of normal fluids, such as the ability to free-flow under gravity, or to be pumped using fluid type technologies.

Well control is the technique used in oil and gas operations such as drilling, well workover, and well completions for maintaining the fluid column hydrostatic pressure and formation pressure to prevent influx of formation fluids into the wellbore. This technique involves the estimation of formation fluid pressures, the strength of the subsurface formations and the use of casing and mud density to offset those pressures in a predictable fashion. Understanding of pressure and pressure relationships are very important in well control.

Mud logging is the creation of a detailed record of a borehole by examining the cuttings of rock brought to the surface by the circulating drilling medium. Mud logging is usually performed by a third-party mud logging company. This provides well owners and producers with information about the lithology and fluid content of the borehole while drilling. Historically it is the earliest type of well log. Under some circumstances compressed air is employed as a circulating fluid, rather than mud. Although most commonly used in petroleum exploration, mud logging is also sometimes used when drilling water wells and in other mineral exploration, where drilling fluid is the circulating medium used to lift cuttings out of the hole. In hydrocarbon exploration, hydrocarbon surface gas detectors record the level of natural gas brought up in the mud. A mobile laboratory is situated by the mud logging company near the drilling rig or on deck of an offshore drilling rig, or on a drill ship.

Underbalanced drilling, or UBD, is a procedure used to drill oil and gas wells where the pressure in the wellbore is kept lower than the static pressure then the formation being drilled. As the well is being drilled, formation fluid flows into the wellbore and up to the surface. This is the opposite of the usual situation, where the wellbore is kept at a pressure above the formation to prevent formation fluid entering the well. In such a conventional "overbalanced" well, the invasion of fluid is considered a kick, and if the well is not shut-in it can lead to a blowout, a dangerous situation. In underbalanced drilling, however, there is a "rotating head" at the surface - essentially a seal that diverts produced fluids to a separator while allowing the drill string to continue rotating.

Drilling fluid invasion is a process that occurs in a well being drilled with higher wellbore pressure than formation pressure. The liquid component of the drilling fluid continues to "invade" the porous and permeable formation until the solids present in the mud, commonly bentonite, clog enough pores to form a mud cake capable of preventing further invasion.

A well kill is the operation of placing a column of heavy fluid into a well bore in order to prevent the flow of reservoir fluids without the need for pressure control equipment at the surface. It works on the principle that the hydrostatic head of the "kill fluid" or "kill mud" will be enough to suppress the pressure of the formation fluids. Well kills may be planned in the case of advanced interventions such as workovers, or be contingency operations. The situation calling for a well kill will dictate the method taken.

The capillary length or capillary constant, is a length scaling factor that relates gravity and surface tension. It is a fundamental physical property that governs the behaviour of menisci, and is found when body forces (gravity) and surface forces are in equilibrium.

The Marsh funnel is a simple device for measuring viscosity by observing the time it takes a known volume of liquid to flow from a cone through a short tube. It is standardized for use by mud engineers to check the quality of drilling mud. Other cones with different geometries and orifice arrangements are called flow cones, but have the same operating principle.

In the oil industry, mud weight is the density of the drilling fluid and is normally measured in pounds per gallon (lb/gal) (ppg) or pound cubic feet (pcf). In the field it is measured using a mud scale or mud balance. Mud can weigh up to 22 or 23 ppg.

A degasser is a device used in drilling to remove gasses from drilling fluid which could otherwise form bubbles.

Oil well control is the management of the dangerous effects caused by the unexpected release of formation fluid, such as natural gas and/or crude oil, upon surface equipment of oil or gas drilling rigs and escaping into the atmosphere. Technically, oil well control involves preventing the formation fluid, usually referred to as kick, from entering into the wellbore during drilling.