Related Research Articles

A cell wall is a structural layer that surrounds some cell types, found immediately outside the cell membrane. It can be tough, flexible, and sometimes rigid. Primarily, it provides the cell with structural support, shape, protection, and functions as a selective barrier. Another vital role of the cell wall is to help the cell withstand osmotic pressure and mechanical stress. While absent in many eukaryotes, including animals, cell walls are prevalent in other organisms such as fungi, algae and plants, and are commonly found in most prokaryotes, with the exception of mollicute bacteria.

Cellulose is an organic compound with the formula (C

6H

10O

5)

n, a polysaccharide consisting of a linear chain of several hundred to many thousands of β(1→4) linked D-glucose units. Cellulose is an important structural component of the primary cell wall of green plants, many forms of algae and the oomycetes. Some species of bacteria secrete it to form biofilms. Cellulose is the most abundant organic polymer on Earth. The cellulose content of cotton fibre is 90%, that of wood is 40–50%, and that of dried hemp is approximately 57%.

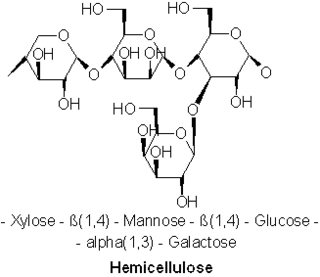

A hemicellulose is one of a number of heteropolymers, such as arabinoxylans, present along with cellulose in almost all terrestrial plant cell walls. Cellulose is crystalline, strong, and resistant to hydrolysis. Hemicelluloses are branched, shorter in length than cellulose, and also show a propensity to crystallize. They can be hydrolyzed by dilute acid or base as well as a myriad of hemicellulase enzymes.

Polysaccharides, or polycarbohydrates, are the most abundant carbohydrates found in food. They are long-chain polymeric carbohydrates composed of monosaccharide units bound together by glycosidic linkages. This carbohydrate can react with water (hydrolysis) using amylase enzymes as catalyst, which produces constituent sugars. They range in structure from linear to highly branched. Examples include storage polysaccharides such as starch, glycogen and galactogen and structural polysaccharides such as hemicellulose and chitin.

Dietary fiber or roughage is the portion of plant-derived food that cannot be completely broken down by human digestive enzymes. Dietary fibers are diverse in chemical composition and can be grouped generally by their solubility, viscosity and fermentability which affect how fibers are processed in the body. Dietary fiber has two main subtypes: soluble fiber and insoluble fiber which are components of plant-based foods such as legumes, whole grains, cereals, vegetables, fruits, and nuts or seeds. A diet high in regular fiber consumption is generally associated with supporting health and lowering the risk of several diseases. Dietary fiber consists of non-starch polysaccharides and other plant components such as cellulose, resistant starch, resistant dextrins, inulin, lignins, chitins, pectins, beta-glucans, and oligosaccharides.

Pectin is a heteropolysaccharide, a structural polymer contained in the primary lamella, in the middle lamella, and in the cell walls of terrestrial plants. The principal chemical component of pectin is galacturonic acid which was isolated and described by Henri Braconnot in 1825. Commercially produced pectin is a white-to-light-brown powder, produced from citrus fruits for use as an edible gelling agent, especially in jams and jellies, dessert fillings, medications, and sweets; as a food stabiliser in fruit juices and milk drinks, and as a source of dietary fiber.

Lignin is a class of complex organic polymers that form key structural materials in the support tissues of most plants. Lignins are particularly important in the formation of cell walls, especially in wood and bark, because they lend rigidity and do not rot easily. Chemically, lignins are polymers made by cross-linking phenolic precursors.

The kraft process (also known as kraft pulping or sulfate process) is a process for conversion of wood into wood pulp, which consists of almost pure cellulose fibres, the main component of paper. The kraft process involves treatment of wood chips with a hot mixture of water, sodium hydroxide (NaOH), and sodium sulfide (Na2S), known as white liquor, that breaks the bonds that link lignin, hemicellulose, and cellulose. The technology entails several steps, both mechanical and chemical. It is the dominant method for producing paper. In some situations, the process has been controversial because kraft plants can release odorous products and in some situations produce substantial liquid wastes.

Banana paper is a type of paper created from banana plant bark or banana peel fibers. Banana paper has a lower density, higher stiffness, higher disposability, higher renewability, and higher tensile strength compared to traditional paper. These qualities are due to the cellular composition of banana fiber, which consists of cellulose, hemicellulose, and lignin.

A pulp mill is a manufacturing facility that converts wood chips or other plant fiber sources into a thick fiber board which can be shipped to a paper mill for further processing. Pulp can be manufactured using mechanical, semi-chemical, or fully chemical methods. The finished product may be either bleached or non-bleached, depending on the customer requirements.

In industrial chemistry, black liquor is the by-product from the kraft process when digesting pulpwood into paper pulp removing lignin, hemicelluloses and other extractives from the wood to free the cellulose fibers.

The rumen, also known as a paunch, is the largest stomach compartment in ruminants and the larger part of the reticulorumen, which is the first chamber in the alimentary canal of ruminant animals. The rumen's microbial favoring environment allows it to serve as the primary site for microbial fermentation of ingested feed. The smaller part of the reticulorumen is the reticulum, which is fully continuous with the rumen, but differs from it with regard to the texture of its lining. It covers approximately 80% of total ruminant stomach portion

Xylan is a type of hemicellulose, a polysaccharide consisting mainly of xylose residues. It is found in plants, in the secondary cell walls of dicots and all cell walls of grasses. Xylan is the third most abundant polysaccharide on Earth, after cellulose and chitin.

Lignocellulose refers to plant dry matter (biomass), so called lignocellulosic biomass. It is the most abundantly available raw material on the Earth for the production of biofuels. It is composed of two kinds of carbohydrate polymers, cellulose and hemicellulose, and an aromatic-rich polymer called lignin. Any biomass rich in cellulose, hemicelluloses, and lignin are commonly referred to as lignocellulosic biomass. Each component has a distinct chemical behavior. Being a composite of three very different components makes the processing of lignocellulose challenging. The evolved resistance to degradation or even separation is referred to as recalcitrance. Overcoming this recalcitrance to produce useful, high value products requires a combination of heat, chemicals, enzymes, and microorganisms. These carbohydrate-containing polymers contain different sugar monomers and they are covalently bound to lignin.

A wood-decay or xylophagous fungus is any species of fungus that digests moist wood, causing it to rot. Some species of wood-decay fungi attack dead wood, such as brown rot, and some, such as Armillaria, are parasitic and colonize living trees. Excessive moisture above the fibre saturation point in wood is required for fungal colonization and proliferation. In nature, this process causes the breakdown of complex molecules and leads to the return of nutrients to the soil. Wood-decay fungi consume wood in various ways; for example, some attack the carbohydrates in wood, and some others decay lignin. The rate of decay of wooden materials in various climates can be estimated by empirical models.

Cellulose fibers are fibers made with ethers or esters of cellulose, which can be obtained from the bark, wood or leaves of plants, or from other plant-based material. In addition to cellulose, the fibers may also contain hemicellulose and lignin, with different percentages of these components altering the mechanical properties of the fibers.

In industrial paper-making processes, organosolv is a pulping technique that uses an organic solvent to solubilise lignin and hemicellulose. It has been considered in the context of both pulp and paper manufacture and biorefining for subsequent conversion of cellulose to fuel ethanol. The process was invented by Theodor Kleinert in 1968 as an environmentally benign alternative to kraft pulping.

Extracellular enzymes or exoenzymes are synthesized inside the cell and then secreted outside the cell, where their function is to break down complex macromolecules into smaller units to be taken up by the cell for growth and assimilation. These enzymes degrade complex organic matter such as cellulose and hemicellulose into simple sugars that enzyme-producing organisms use as a source of carbon, energy, and nutrients. Grouped as hydrolases, lyases, oxidoreductases and transferases, these extracellular enzymes control soil enzyme activity through efficient degradation of biopolymers.

Feed manufacturing refers to the process of producing animal feed from raw agricultural products. Fodder produced by manufacturing is formulated to meet specific animal nutrition requirements for different species of animals at different life stages. According to the American Feed Industry Association (AFIA), there are four basic steps:

- Receive raw ingredients: Feed mills receive raw ingredients from suppliers. Upon arrival, the ingredients are weighed, tested and analyzed for various nutrients and to ensure their quality and safety.

- Create a formula: Nutritionists work side by side with scientists to formulate nutritionally sound and balanced diets for livestock, poultry, aquaculture and pets. This is a complex process, as every species has different nutritional requirements.

- Mix ingredients: Once the formula is determined, the mill mixes the ingredients to create a finished product.

- Package and label: Manufacturers determine the best way to ship the product. If it is prepared for retail, it will be "bagged and tagged," or placed into a bag with a label that includes the product's purpose, ingredients and instructions. If the product is prepared for commercial use, it will be shipped in bulk.

High performance sport dogs are those bred and trained to compete in various athletic events. Events include but are not limited to, agility trials, hunting and racing. These events are physically and metabolically demanding. As a result, canine athletes require specialized nutrition in order to perform at high levels during events and for maintenance and recovery. The main nutritional concern for sport dogs is adequate energy. A well-balanced diet, containing the appropriate amounts of protein, fat, carbohydrate, fiber and micronutrients is essential to meet these energy requirements.

References

- ↑ Van Soest, P. J., J. B. Robertson, and B. A. Lewis. 1991. Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J. Dairy Sci. 74:3583–3597.

- ↑ AOAC Official Method 2002.04 Amylase-Treated Neutral Detergent Fiber in Feeds.

- ↑ Agri Analysis. "Feed and Forage Terminology". Agri Analysis. Archived from the original on June 9, 2017. Retrieved November 24, 2016.