A wire is a flexible strand of metal.

Thousands of configurations of connectors are manufactured for power, data, and audiovisual applications. Electrical connectors can be divided into four basic categories, differentiated by their function:

A braid is a complex structure or pattern formed by interlacing two or more strands of flexible material such as textile yarns, wire, or hair.

A winch is a mechanical device that is used to pull in or let out or otherwise adjust the tension of a rope or wire rope.

An elevated passenger ropeway, or chairlift, is a type of aerial lift, which consists of a continuously circulating steel wire rope loop strung between two end terminals and usually over intermediate towers, carrying a series of chairs. They are the primary onhill transport at most ski areas, but are also found at amusement parks, various tourist attractions, and increasingly in urban transport.

A ferrule is any of a number of types of objects, generally used for fastening, joining, sealing, or reinforcement. They are often narrow circular rings made from metal, or less commonly, plastic. Ferrules are also often referred to as eyelets or grommets within the manufacturing industry.

A rope is a group of yarns, plies, fibres, or strands that are twisted or braided together into a larger and stronger form. Ropes have tensile strength and so can be used for dragging and lifting. Rope is thicker and stronger than similarly constructed cord, string, and twine.

Rope splicing in ropework is the forming of a semi-permanent joint between two ropes or two parts of the same rope by partly untwisting and then interweaving their strands. Splices can be used to form a stopper at the end of a line, to form a loop or an eye in a rope, or for joining two ropes together. Splices are preferred to knotted rope, since while a knot typically reduces the strength by 20–40%, a splice is capable of attaining a rope's full strength. However, splicing usually results in a thickening of the line and, if subsequently removed, leaves a distortion of the rope. Most types of splices are used on 3-strand rope, but some can be done on 12-strand or greater single-braided rope, as well as most double braids.

While a spliced 3-strand rope's strands are interwoven to create the splice, a braided rope's splice is constructed by simply pulling the rope into its jacket.

Electrical wiring is an electrical installation of cabling and associated devices such as switches, distribution boards, sockets, and light fittings in a structure.

Swaging is a forging process in which the dimensions of an item are altered using dies into which the item is forced. Swaging is usually a cold working process, but also may be hot worked.

A power cable is an electrical cable, an assembly of one or more electrical conductors, usually held together with an overall sheath. The assembly is used for transmission of electrical power. Power cables may be installed as permanent wiring within buildings, buried in the ground, run overhead, or exposed. Power cables that are bundled inside thermoplastic sheathing and that are intended to be run inside a building are known as NM-B.

Aluminum building wiring is a type of electrical wiring for residential construction or houses that uses aluminum electrical conductors. Aluminum provides a better conductivity to weight ratio than copper, and therefore is also used for wiring power grids, including overhead power transmission lines and local power distribution lines, as well as for power wiring of some airplanes. Utility companies have used aluminum wire for electrical transmission in power grids since around the late 1800s to the early 1900s. It has cost and weight advantages over copper wires. Aluminum wire in power transmission and distribution applications is still the preferred material today.

Mineral-insulated copper-clad cable is a variety of electrical cable made from copper conductors inside a copper sheath, insulated by inorganic magnesium oxide powder. The name is often abbreviated to MICC or MI cable, and colloquially known as pyro. A similar product sheathed with metals other than copper is called mineral insulated metal sheathed (MIMS) cable.

Wire rope is several strands of metal wire twisted into a helix forming a composite rope, in a pattern known as laid rope. Larger diameter wire rope consists of multiple strands of such laid rope in a pattern known as cable laid.

The eye splice is a method of creating a permanent loop in the end of a rope by means of rope splicing.

An electrical crimp is a type of solderless electrical connection.

Copper has been used in electrical wiring since the invention of the electromagnet and the telegraph in the 1820s. The invention of the telephone in 1876 created further demand for copper wire as an electrical conductor.

Wire rope spooling technology is the technology to prevent wire rope getting snagged when spooled, especially in multiple layers on a drum.

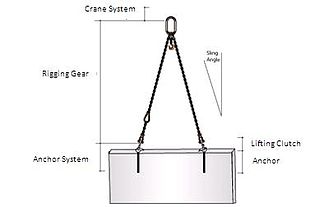

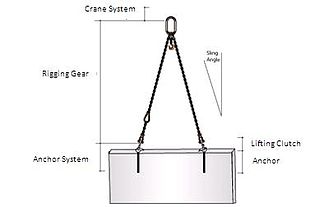

Rigging is both a noun, the equipment, and verb, the action of designing and installing the equipment, in the preparation to move objects. A team of riggers design and install the lifting or rolling equipment needed to raise, roll, slide or lift objects such as with a crane, hoist or block and tackle.

In telecommunications, a line splice is a method of connecting electrical cables or optical fibers.