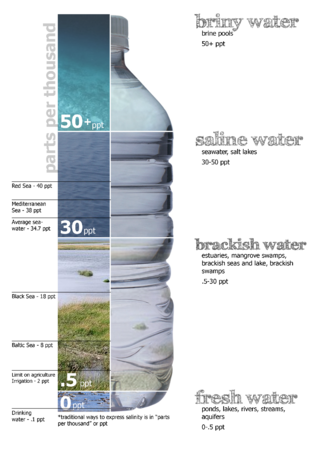

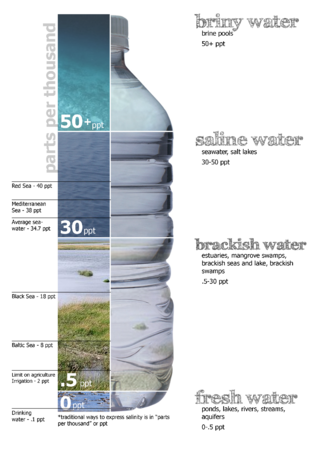

Brine is water with a high-concentration solution of salt. In diverse contexts, brine may refer to the salt solutions ranging from about 3.5% up to about 26%. Brine forms naturally due to evaporation of ground saline water but it is also generated in the mining of sodium chloride. Brine is used for food processing and cooking, for de-icing of roads and other structures, and in a number of technological processes. It is also a by-product of many industrial processes, such as desalination, so it requires wastewater treatment for proper disposal or further utilization.

Waste management or waste disposal includes the processes and actions required to manage waste from its inception to its final disposal. This includes the collection, transport, treatment, and disposal of waste, together with monitoring and regulation of the waste management process and waste-related laws, technologies, and economic mechanisms.

Environmental remediation is the cleanup of hazardous substances dealing with the removal, treatment and containment of pollution or contaminants from environmental media such as soil, groundwater, sediment. Remediation may be required by regulations before development of land revitalization projects. Developers who agree to voluntary cleanup may be offered incentives under state or municipal programs like New York State's Brownfield Cleanup Program. If remediation is done by removal the waste materials are simply transported off-site for disposal at another location. The waste material can also be contained by physical barriers like slurry walls. The use of slurry walls is well-established in the construction industry. The application of (low) pressure grouting, used to mitigate soil liquefaction risks in San Francisco and other earthquake zones, has achieved mixed results in field tests to create barriers, and site-specific results depend upon many variable conditions that can greatly impact outcomes.

In mining, tailings or tails are the materials left over after the process of separating the valuable fraction from the uneconomic fraction (gangue) of an ore. Tailings are different from overburden, which is the waste rock or other material that overlies an ore or mineral body and is displaced during mining without being processed.

Wastewater treatment is a process which removes and eliminates contaminants from wastewater and converts this into an effluent that can be returned to the water cycle. Once returned to the water cycle, the effluent creates an acceptable impact on the environment or is reused for various purposes. The treatment process takes place in a wastewater treatment plant. There are several kinds of wastewater which are treated at the appropriate type of wastewater treatment plant. For domestic wastewater, the treatment plant is called a Sewage Treatment. For industrial wastewater, treatment either takes place in a separate Industrial wastewater treatment, or in a sewage treatment plant. Further types of wastewater treatment plants include Agricultural wastewater treatment and leachate treatment plants.

Pomace, or marc, is the solid remains of grapes, olives, or other fruit after pressing for juice or oil. It contains the skins, pulp, seeds, and stems of the fruit.

A supercritical fluid (SCF) is any substance at a temperature and pressure above its critical point, where distinct liquid and gas phases do not exist, but below the pressure required to compress it into a solid. It can effuse through porous solids like a gas, overcoming the mass transfer limitations that slow liquid transport through such materials. SCF are superior to gases in their ability to dissolve materials like liquids or solids. Also, near the critical point, small changes in pressure or temperature result in large changes in density, allowing many properties of a supercritical fluid to be "fine-tuned".

Industrial wastewater treatment describes the processes used for treating wastewater that is produced by industries as an undesirable by-product. After treatment, the treated industrial wastewater may be reused or released to a sanitary sewer or to a surface water in the environment. Some industrial facilities generate wastewater that can be treated in sewage treatment plants. Most industrial processes, such as petroleum refineries, chemical and petrochemical plants have their own specialized facilities to treat their wastewaters so that the pollutant concentrations in the treated wastewater comply with the regulations regarding disposal of wastewaters into sewers or into rivers, lakes or oceans. This applies to industries that generate wastewater with high concentrations of organic matter, toxic pollutants or nutrients such as ammonia. Some industries install a pre-treatment system to remove some pollutants, and then discharge the partially treated wastewater to the municipal sewer system.

Olive oil extraction is the process of extracting the olive oil present in olive drupes. Olive oil is produced in the mesocarp cells, and stored in a particular type of vacuole called a lipo vacuole, i.e., every cell contains a tiny olive oil droplet. Olive oil extraction is the process of separating the oil from the other fruit contents. It is possible to attain this separation by physical means alone, i.e., oil and water do not mix, so they are relatively easy to separate. This contrasts with other oils that are extracted with chemical solvents, generally hexane. The first operation when extracting olive oil is washing the olives, to reduce the presence of contaminants, especially soil which can create a particular flavor effect called "soil taste".

Liquid–liquid extraction, also known as solvent extraction and partitioning, is a method to separate compounds or metal complexes, based on their relative solubilities in two different immiscible liquids, usually water (polar) and an organic solvent (non-polar). There is a net transfer of one or more species from one liquid into another liquid phase, generally from aqueous to organic. The transfer is driven by chemical potential, i.e. once the transfer is complete, the overall system of chemical components that make up the solutes and the solvents are in a more stable configuration. The solvent that is enriched in solute(s) is called extract. The feed solution that is depleted in solute(s) is called the raffinate. Liquid-liquid extraction is a basic technique in chemical laboratories, where it is performed using a variety of apparatus, from separatory funnels to countercurrent distribution equipment called as mixer settlers. This type of process is commonly performed after a chemical reaction as part of the work-up, often including an acidic work-up.

Waste-to-energy (WtE) or energy-from-waste (EfW) is the process of generating energy in the form of electricity and/or heat from the primary treatment of waste, or the processing of waste into a fuel source. WtE is a form of energy recovery. Most WtE processes generate electricity and/or heat directly through combustion, or produce a combustible fuel commodity, such as methane, methanol, ethanol or synthetic fuels, often derived from the product syngas.

Shale oil extraction is an industrial process for unconventional oil production. This process converts kerogen in oil shale into shale oil by pyrolysis, hydrogenation, or thermal dissolution. The resultant shale oil is used as fuel oil or upgraded to meet refinery feedstock specifications by adding hydrogen and removing sulfur and nitrogen impurities.

Environmental impact of the oil shale industry includes the consideration of issues such as land use, waste management, and water and air pollution caused by the extraction and processing of oil shale. Surface mining of oil shale deposits causes the usual environmental impacts of open-pit mining. In addition, the combustion and thermal processing generate waste material, which must be disposed of, and harmful atmospheric emissions, including carbon dioxide, a major greenhouse gas. Experimental in-situ conversion processes and carbon capture and storage technologies may reduce some of these concerns in future, but may raise others, such as the pollution of groundwater.

Olive mill pomace is a by-product from the olive oil mill extraction process. Usually it is used as fuel in a cogeneration system or as organic fertiliser after a composting operation.

Solid waste policy in the United States is aimed at developing and implementing proper mechanisms to effectively manage solid waste. For solid waste policy to be effective, inputs should come from stakeholders, including citizens, businesses, community-based organizations, non-governmental organizations, government agencies, universities, and other research organizations. These inputs form the basis of policy frameworks that influence solid waste management decisions. In the United States, the Environmental Protection Agency (EPA) regulates household, industrial, manufacturing, and commercial solid and hazardous wastes under the 1976 Resource Conservation and Recovery Act (RCRA). Effective solid waste management is a cooperative effort involving federal, state, regional, and local entities. Thus, the RCRA's Solid Waste program section D encourages the environmental departments of each state to develop comprehensive plans to manage nonhazardous industrial and municipal solid waste.

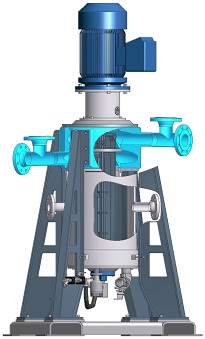

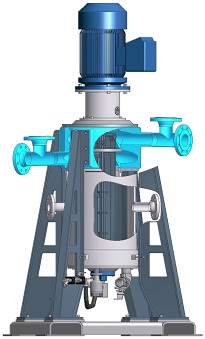

A centrifugal extractor—also known as a centrifugal contactor or annular centrifugal contactor—uses the rotation of the rotor inside a centrifuge to mix two immiscible liquids outside the rotor and to separate the liquids in the field of gravity inside the rotor. This way, a centrifugal extractor generates a continuous extraction from one liquid phase into another liquid phase.

Single cell oil, also known as Microbial oil consists of the intracellular storage lipids, triacyglycerols. It is similar to vegetable oil, another biologically produced oil. They are produced by oleaginous microorganisms, which is the term for those bacteria, molds, algae and yeast, which can accumulate 20% to 80% lipids of their biomass. The accumulation of lipids take place by the end of logarithmic phase and continues during station phase until carbon source begins to reduce with nutrition limitation.

A separation process is a method that converts a mixture or a solution of chemical substances into two or more distinct product mixtures, a scientific process of separating two or more substance in order to obtain purity. At least one product mixture from the separation is enriched in one or more of the source mixture's constituents. In some cases, a separation may fully divide the mixture into pure constituents. Separations exploit differences in chemical properties or physical properties between the constituents of a mixture.

A centrifuge is a device that employs a high rotational speed to separate components of different densities. This becomes relevant in the majority of industrial jobs where solids, liquids and gases are merged into a single mixture and the separation of these different phases is necessary. A decanter centrifuge separates continuously solid materials from liquids in the slurry, and therefore plays an important role in the wastewater treatment, chemical, oil, and food processing industries. There are several factors that affect the performance of a decanter centrifuge, and some design heuristics are to be followed which are dependent upon given applications.