Palliser shot is an early British armour-piercing artillery projectile, intended to pierce the armour protection of warships being developed in the second half of the 19th century. It was invented by Sir William Palliser, after whom it is named.

Palliser shot is an early British armour-piercing artillery projectile, intended to pierce the armour protection of warships being developed in the second half of the 19th century. It was invented by Sir William Palliser, after whom it is named.

Major Palliser's shot, approved 21 October 1867, was an improvement over the ordinary elongated shot of the time.

It was adopted for the larger types of rifled muzzle-loading guns rifled on the Woolwich principle (with three rifling grooves). Palliser shot in many calibres stayed in service in the armour-piercing role until phased out of (British) service in 1909 for naval and fortress use, and 1921 for land service. [1]

At the Battle of Angamos (8 October 1879) the Chilean ironclad warships fired twenty 250-pound Palliser gunshots against the Peruvian monitor Huáscar , with devastating results. It was the first time that such piercing shells were used in combat. [2]

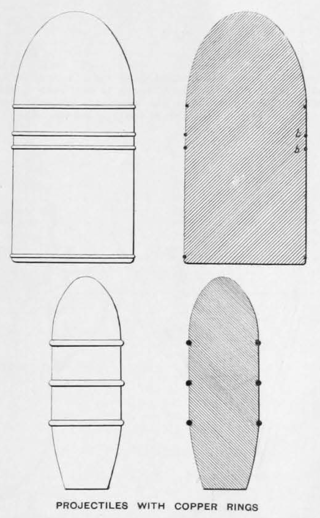

Palliser shot was made of cast iron, the head being chilled in casting to harden it, using composite moulds with a metal, water-cooled portion for the head. At times there were defects that led to cracking in the projectiles, but these were overcome with time. Bronze studs were installed into the outside of the projectile so as to engage the rifling grooves in the gun barrel. The base had a hollow pocket but was not filled with powder or explosive: the cavity was necessitated by difficulties in casting large solid projectiles without them cracking when they cooled, because the nose and base of the projectiles cooled at different rates, and in fact a larger cavity facilitated a better-quality casting. [3] The hole at the base was threaded to accept a copper gas check. This prevented propellant gases from blowing around the projectile, providing obturation as the driving band had yet to be perfected. Later designs did away with the studs on the projectile body, with the gas checks being set with grooves to impart spin to the projectile.

Britain also deployed Palliser shells in the 1870s–1880s. In the shell the cavity was slightly larger than in the shot and was filled with gunpowder instead of being empty, to provide a small explosive effect after penetrating armour plating. The shell was correspondingly slightly longer than the shot to compensate for the lighter cavity. The powder filling was ignited by the shock of impact and hence did not require a fuze. While these Palliser shells were effective against unhardened iron, British doctrine held that only shot (i.e. non-explosive projectiles) were suitable for penetrating the new hardened armour being developed in the 1880s; hence the gunpowder filling was discontinued. [4]

A bullet is a kinetic projectile, a component of firearm ammunition that is shot from a gun barrel. They are made of a variety of materials, such as copper, lead, steel, polymer, rubber and even wax; and are made in various shapes and constructions, including specialized functions such as hunting, target shooting, training, and combat. Bullets are often tapered, making them more aerodynamic. Bullet size is expressed by weight and diameter in both imperial and metric measurement systems. Bullets do not normally contain explosives but strike or damage the intended target by transferring kinetic energy upon impact and penetration.

Rotation of ammunition is a term used with reference to guns. Projectiles intended for RML guns were at first fitted with a number of gun-metal studs arranged around them in a spiral manner corresponding to the twist of rifling. Invented in mid-1840s by Giovanni Cavalli, this method was defective, as it allowed, as in the old smooth-bore guns, the powder gas to escape by the clearance between the projectile and the bore, with a consequent loss of efficiency; it also quickly eroded the bore of the larger guns. Multiple solution to the problems were invented in two following decades, both for muzzle-loaders and breech-loaders.

Armour-piercing ammunition (AP) is a type of projectile designed to penetrate armour protection, most often including naval armour, body armour, vehicle armour.

A shell, in a military context, is a projectile whose payload contains an explosive, incendiary, or other chemical filling. Originally it was called a bombshell, but "shell" has come to be unambiguous in a military context. A shell can hold a tracer.

A gun barrel is a crucial part of gun-type weapons such as small firearms, artillery pieces, and air guns. It is the straight shooting tube, usually made of rigid high-strength metal, through which a contained rapid expansion of high-pressure gas(es) is used to propel a projectile out of the front end (muzzle) at a high velocity. The hollow interior of the barrel is called the bore, and the diameter of the bore is called its caliber, usually measured in inches or millimetres.

This article explains terms used for the British Armed Forces' ordnance (weapons) and ammunition. The terms may have different meanings depending on its usage in another country's military.

Armour-piercing, capped, ballistic capped (APCBC) is a type of configuration for armour-piercing ammunition introduced in the 1930s to improve the armour-piercing capabilities of both naval and anti-tank guns. The configuration consists of an armour-piercing shell fitted with a stubby armour-piercing cap for improved penetration properties against surface hardened armour, especially at high impact angles, and an aerodynamic ballistic cap on top of the AP cap to correct for the poorer aerodynamics, especially higher drag, otherwise created by the stubby AP cap. These features allow APCBC shells to retain higher velocities and to deliver more energy to the target on impact, especially at long range when compared to uncapped shells.

An Armstrong gun was a uniquely designed type of rifled breech-loading field and heavy gun designed by Sir William Armstrong and manufactured in England beginning in 1855 by the Elswick Ordnance Company and the Royal Arsenal at Woolwich. Such guns involved a built-up gun construction system of a wrought-iron tube surrounded by a number of wrought-iron strengthening coils shrunk over the inner tube to keep it under compression.

The following are terms related to firearms and ammunition topics.

Ammunition is the material fired, scattered, dropped, or detonated from any weapon or weapon system. Ammunition is both expendable weapons and the component parts of other weapons that create the effect on a target.

The RML 10-inch guns Mk I – Mk II were large rifled muzzle-loading guns designed for British battleships and monitors in the 1860s to 1880s. They were also fitted to the Bouncer and Ant-class flat-iron gunboats. They were also used for fixed coastal defences around the United Kingdom and around the British Empire until the early years of the 20th century.

The RML 9-inch guns Mark I – Mark VI were large rifled muzzle-loading guns of the 1860s used as primary armament on smaller British ironclad battleships and secondary armament on larger battleships, and also ashore for coast defence. It should not be confused with the RML 9-inch Armstrong Gun, used by the Dutch navy, the Spanish Navy, and other navies.

The RML 12.5-inch guns were large rifled muzzle-loading guns designed for British battleships and were also employed for coast defence.

RML 16-inch 80-ton guns were large rifled muzzle-loading guns intended to give the largest British battleships parity with the large guns being mounted by Italian and French ships in the Mediterranean Sea in the 1870s.

The RML 12-inch 25-ton guns were large rifled muzzle-loading guns of mid-late 1800s used as primary armament on British ironclad turret battleships and coastal monitors, and also ashore for coast defence. They were the shorter and less powerful of the two 12-inch (305-mm) British RML guns, the other being the 35-ton gun.

RML 12-inch 35-ton guns were large rifled muzzle-loading guns used as primary armament on British battleships of the 1870s. They were the longer and more powerful of the two 12-inch British RML guns, the other being the 25-ton gun.

RML 11-inch 25-ton guns were large rifled muzzle-loading guns used as primary armament on British battleships and for coastal defence. They were effectively the same gun as the RML 12-inch 25-ton gun, bored to 11 inches instead of 12.

The 68-pounder cannon was an artillery piece designed and used by the British Armed Forces in the mid-19th century. The cannon was a smoothbore muzzle-loading gun manufactured in several weights, the most common being 95 long cwt (4,800 kg), and fired projectiles of 68 lb (31 kg). Colonel William Dundas designed the 112 cwt version in 1841 and it was cast the following year. The most common variant, weighing 95 cwt, dates from 1846. It entered service with the Royal Artillery and the Royal Navy and saw active service with both arms during the Crimean War. Over 2,000 were made and it gained a reputation as the finest smoothbore cannon ever made.

The RML 7-inch guns were various designs of medium-sized rifled muzzle-loading guns used to arm small to medium-sized British warships in the late 19th century, and some were used ashore for coast defence.

Gas-checks were attachments to ammunition that revolutionised the performance of RML heavy guns. The first generation of RML heavy guns began entering service in about 1865. They all had Woolwich rifling and relied on studs on the projectiles for rotation. Gas-checks were first introduced in 1878 or soon after. They significantly reduced wear on the guns while also increasing their range and accuracy. Before long, studless ammunition was being manufactured for these guns, using gas-checks for projectile rotation. Gas-checks also facilitated a switch to the second generation of RML guns which used polygroove rifling and only supported studless ammunition.