A rifle is a long-barreled firearm designed for accurate shooting, with a barrel that has a helical pattern of grooves (rifling) cut into the bore wall. In keeping with their focus on accuracy, rifles are typically designed to be held with both hands and braced firmly against the shooter's shoulder via a buttstock for stability during shooting. Rifles are used extensively in warfare, self defense, law enforcement, crime, hunting, and shooting sports.

A bullet is a kinetic projectile, a component of firearm ammunition that is shot from a gun barrel. Bullets are made of a variety of materials, such as copper, lead, steel, polymer, rubber and even wax. Bullets are made in various shapes and constructions, including specialized functions such as hunting, target shooting, training and combat. Bullets are often tapered, making them more aerodynamic. Bullet sizes are expressed by their weights and diameters in both imperial and metric measurement systems. For example: 55 grain .223 caliber bullets are of the same weight and caliber as 3.56 gram 5.56mm caliber bullets. Bullets do not normally contain explosives but strike or damage the intended target by transferring kinetic energy upon impact and penetration. Bullets shot by firearms can be used for target practice or to injure or kill animals or people.

In firearms, rifling is machining helical grooves into the internal (bore) surface of a gun's barrel for the purpose of exerting torque and thus imparting a spin to a projectile around its longitudinal axis during shooting to stabilize the projectile longitudinally by conservation of angular momentum, improving its aerodynamic stability and accuracy over smoothbore designs.

A driving band or rotating band is a band of soft metal near the base of an artillery shell, often made of gilding metal, copper, or lead. When the shell is fired, the pressure of the propellant swages the metal into the rifling of the barrel and forms a seal; this seal prevents the gases from blowing past the shell, and engages the barrel's rifling to spin-stabilize the shell.

A gun barrel is a crucial part of gun-type weapons such as small firearms, artillery pieces and air guns. It is the straight shooting tube, usually made of rigid high-strength metal, through which a contained rapid expansion of high-pressure gas(es) is used to propel a projectile out of the front end (muzzle) at a high velocity. The hollow interior of the barrel is called the bore, and the diameter of the bore is called its caliber, usually measured in inches or millimetres.

Internal ballistics, a subfield of ballistics, is the study of the propulsion of a projectile.

A rifled breech loader (RBL) is an artillery piece which, unlike the smoothbore cannon and rifled muzzle loader (RML) which preceded it, has rifling in the barrel and is loaded from the breech at the rear of the gun.

This article explains terms used for the British Armed Forces' ordnance and also ammunition. The terms may have slightly different meanings in the military of other countries.

Polygonal rifling is a type of gun barrel rifling where the traditional sharp-edged "lands and grooves" are replaced by less pronounced "hills and valleys", so the barrel bore has a polygonal cross-sectional profile.

The Armstrong RBL 7-inch gun, also known as the 110-pounder, was an early attempt to use William Armstrong's new and innovative rifled breechloading mechanism for heavy rifled guns.

A muzzle-loading rifle is a muzzle-loaded small arm or artillery piece that has a rifled barrel rather than a smoothbore. The term "rifled muzzle loader" typically is used to describe a type of artillery piece, although it is technically accurate for small arms as well. A shoulder arm is typically just called a "rifle", as almost all small arms were rifled by the time breechloading became prevalent. Muzzle and breechloading artillery served together for several decades, making a clear distinction more important. In the case of artillery, the abbreviation "RML" is often prefixed to the guns designation; a Rifled breech loader would be "RBL", or often just "BL", since smoothbore breechloading artillery is almost nonexistent. A muzzle loading weapon is loaded through the muzzle, or front of the barrel. This is the opposite of a breech-loading weapon or rifled breechloader (RBL), which is loaded from the breech-end of the barrel. The rifling grooves cut on the inside of the barrel cause the projectile to spin rapidly in flight, giving it greater stability and hence range and accuracy than smoothbore guns. Hand held rifles were well-developed by the 1740s. A popularly recognizable form of the "muzzleloader" is the Kentucky Rifle, which was actually developed in Pennsylvania. The American Longrifle evolved from the German "Jäger" rifle.

An Armstrong gun was a uniquely designed type of rifled breech-loading field and heavy gun designed by Sir William Armstrong and manufactured in England beginning in 1855 by the Elswick Ordnance Company and the Royal Arsenal at Woolwich. Such guns involved a built-up gun construction system of a wrought-iron tube surrounded by a number of wrought-iron strengthening coils shrunk over the inner tube to keep it under compression.

The RML 9-inch guns Mark I – Mark VI were large rifled muzzle-loading guns of the 1860s used as primary armament on smaller British ironclad battleships and secondary armament on larger battleships, and also ashore for coast defence. It should not be confused with the RML 9-inch Armstrong Gun, used by the Dutch navy, the Spanish Navy, and other navies.

The RML 12.5-inch guns were large rifled muzzle-loading guns designed for British battleships and were also employed for coast defence.

RML 16-inch 80-ton guns were large rifled muzzle-loading guns intended to give the largest British battleships parity with the large guns being mounted by Italian and French ships in the Mediterranean Sea in the 1870s.

In artillery, caliber or calibre is the internal diameter of a gun barrel, or - by extension - a relative measure of the barrel length.

The British RML 8-inch 9-ton guns Mark I – Mark III were medium rifled muzzle-loading guns used to arm smaller ironclad warships and coast defence batteries in the later 19th century.

Gas-checks were attachments to ammunition that revolutionised the performance of RML heavy guns. The first generation of RML heavy guns began entering service in about 1865. They all had Woolwich rifling and relied on studs on the projectiles for rotation. Gas-checks were first introduced in 1878 or soon after. They significantly reduced wear on the guns while also increasing their range and accuracy. Before long, studless ammunition was being manufactured for these guns, using gas-checks for projectile rotation. Gas-checks also facilitated a switch to the second generation of RML guns which used polygroove rifling and only supported studless ammunition.

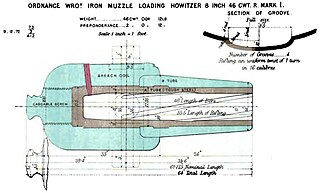

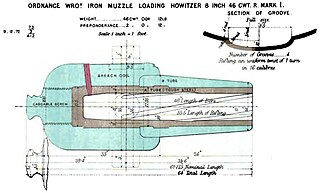

The RML 8-inch howitzer was a British Rifled, Muzzle Loading (RML) Howitzer manufactured in England in the 19th century, which fired a projectile weighing approximately 180 pounds (82 kg). It was used in siege batteries and in fortifications.

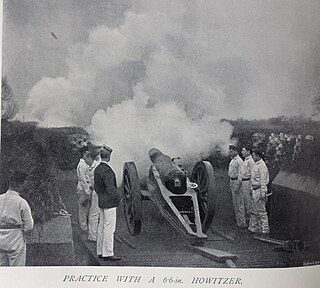

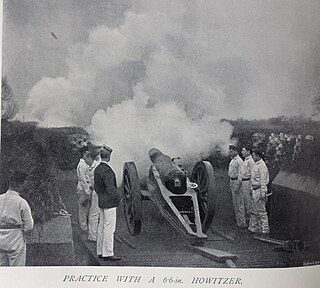

The RML 6.6 inch howitzer was a British Rifled, Muzzle Loading (RML) Howitzer manufactured in England in the 19th century, which fired a projectile weighing approximately 100 pounds (45 kg). It was used in siege batteries and in fortifications.