Related Research Articles

A clutch is a mechanical device that allows an output shaft to be disconnected from a rotating input shaft. The clutch's input shaft is typically attached to a motor, while the clutch's output shaft is connected to the mechanism that does the work.

Disk storage is a data storage mechanism based on a rotating disk. The recording employs various electronic, magnetic, optical, or mechanical changes to the disk's surface layer. A disk drive is a device implementing such a storage mechanism. Notable types are hard disk drives (HDD), containing one or more non-removable rigid platters; the floppy disk drive (FDD) and its removable floppy disk; and various optical disc drives (ODD) and associated optical disc media.

A floppy disk or floppy diskette is a type of disk storage composed of a thin and flexible disk of a magnetic storage medium in a square or nearly square plastic enclosure lined with a fabric that removes dust particles from the spinning disk. The three most popular floppy disks are the 8-inch, 5¼-inch, and 3½-inch floppy disks. Floppy disks store digital data which can be read and written when the disk is inserted into a floppy disk drive (FDD) connected to or inside a computer or other device.

A cam is a rotating or sliding piece in a mechanical linkage used especially in transforming rotary motion into linear motion. It is often a part of a rotating wheel or shaft that strikes a lever at one or more points on its circular path. The cam can be a simple tooth, as is used to deliver pulses of power to a steam hammer, for example, or an eccentric disc or other shape that produces a smooth reciprocating motion in the follower, which is a lever making contact with the cam. A cam timer is similar, and were widely used for electric machine control before the advent of inexpensive electronics, microcontrollers, integrated circuits, programmable logic controllers and digital control.

A coupling is a device used to connect two shafts together at their ends for the purpose of transmitting power. The primary purpose of couplings is to join two pieces of rotating equipment while permitting some degree of misalignment or end movement or both. In a more general context, a coupling can also be a mechanical device that serves to connect the ends of adjacent parts or objects. Couplings do not normally allow disconnection of shafts during operation, however there are torque-limiting couplings which can slip or disconnect when some torque limit is exceeded. Selection, installation and maintenance of couplings can lead to reduced maintenance time and maintenance cost.

Guts or disc guts is a disc game inspired by dodgeball, involving teams throwing a flying disc at members of the opposing team.

A disc tumbler or disc detainer lock is a lock composed of slotted rotating detainer discs. The lock was invented by Finnish founder of Abloy, Emil Henriksson (1886–1959) in 1907 and first manufactured under the Abloy brand in 1918.

A combination lock is a type of locking device in which a sequence of symbols, usually numbers, is used to open the lock. The sequence may be entered using a single rotating dial which interacts with several discs or cams, by using a set of several rotating discs with inscribed symbols which directly interact with the locking mechanism, or through an electronic or mechanical keypad. Types range from inexpensive three-digit luggage locks to high-security safes. Unlike ordinary padlocks, combination locks do not use keys.

A connecting rod, also called a 'con rod', is the part of a piston engine which connects the piston to the crankshaft. Together with the crank, the connecting rod converts the reciprocating motion of the piston into the rotation of the crankshaft. The connecting rod is required to transmit the compressive and tensile forces from the piston. In its most common form, in an internal combustion engine, it allows pivoting on the piston end and rotation on the shaft end.

A ball mill is a type of grinder filled with grinding balls, used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

The Portsmouth Block Mills form part of the Portsmouth Dockyard at Portsmouth, Hampshire, England, and were built during the Napoleonic Wars to supply the British Royal Navy with pulley blocks. They started the age of mass-production using all-metal machine tools, and are regarded as one of the seminal buildings of the British Industrial Revolution. They are also the site of the first stationary steam engines used by the Admiralty.

A mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes. There are many different types of mills and many types of materials processed in them. Historically mills were powered by hand or by animals, working animal, wind (windmill) or water (watermill). In modern era, they are usually powered by electricity.

A chamfer is a transitional edge between two faces of an object. Sometimes defined as a form of bevel, it is often created at a 45° angle between two adjoining right-angled faces.

Padlocks are portable locks usually with a shackle that may be passed through an opening to prevent use, theft, vandalism or harm.

Floppy disk format and density refer to the logical and physical layout of data stored on a floppy disk. Since their introduction, there have been many popular and rare floppy disk types, densities, and formats used in computing, leading to much confusion over their differences. In the early 2000s, most floppy disk types and formats became obsolete, leaving the 3+1⁄2-inch disk, using an IBM PC compatible format of 1440 KB, as the only remaining popular format.

A cycloidal drive or cycloidal speed reducer is a mechanism for reducing the speed of an input shaft by a certain ratio. Cycloidal speed reducers are capable of relatively high ratios in compact sizes with very low backlash.

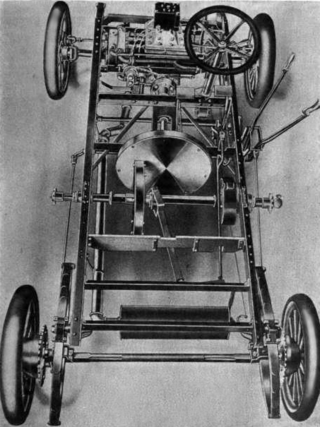

A friction drive or friction engine is a type of transmission that utilises the static friction of two smooth surfaces to transfer torque between two rotating parts.

Lock bumping is a lock picking technique for opening a pin tumbler lock using a specially crafted bump key, rapping key or 999 key. A bump key must correspond to the target lock in order to function correctly.

Surface grinding is done on flat surfaces to produce a smooth finish.

Gab valve gear was an early form of valve gear used on steam engines. Its simplest form allowed an engine to be stopped and started. A double form, mostly used on steam locomotives, allowed easy reversing.

References

- 1 2 Geōrgios D. Sarabakos; Athanasios E. Kosaropoulos (2002). Handbook of Food Processing Equipment. NY: Kluwer Academic / Plenum Publishing. p. 161. ISBN 0306472767.

- ↑ Williams, Robert O. (2012). Formulating Poorly Water Soluble Drugs. Springer. pp. 147–150. ISBN 9781461411444.