Related Research Articles

In telecommunication, the term outside plant has the following meanings:

Plumbing is any system that conveys fluids for a wide range of applications. Plumbing uses pipes, valves, plumbing fixtures, tanks, and other apparatuses to convey fluids. Heating and cooling (HVAC), waste removal, and potable water delivery are among the most common uses for plumbing, but it is not limited to these applications. The word derives from the Latin for lead, plumbum, as the first effective pipes used in the Roman era were lead pipes.

A flange is a protruded ridge, lip or rim, either external or internal, that serves to increase strength ; for easy attachment/transfer of contact force with another object ; or for stabilizing and guiding the movements of a machine or its parts. Flanges are often attached using bolts in the pattern of a bolt circle.

A drain cleaner or opener is a person, device or product unblocking sewer pipes or clogged wastewater drains. The term usually refers to a chemical or mechanical utensil such as a commercial chemical product, plumber's snake, drain auger or toilet plunger. Occasionally, it is applied to a plumber or another individual who performs the drain cleaning and hygiene.

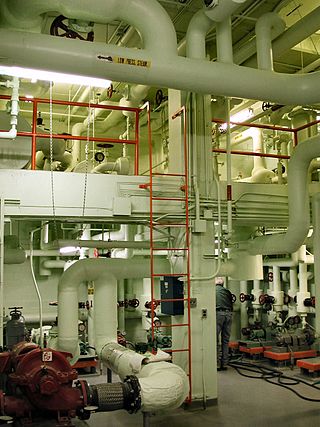

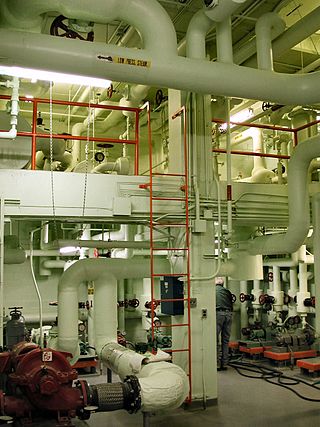

Within industry, piping is a system of pipes used to convey fluids from one location to another. The engineering discipline of piping design studies the efficient transport of fluid.

A chemical plant is an industrial process plant that manufactures chemicals, usually on a large scale. The general objective of a chemical plant is to create new material wealth via the chemical or biological transformation and or separation of materials. Chemical plants use specialized equipment, units, and technology in the manufacturing process. Other kinds of plants, such as polymer, pharmaceutical, food, and some beverage production facilities, power plants, oil refineries or other refineries, natural gas processing and biochemical plants, water and wastewater treatment, and pollution control equipment use many technologies that have similarities to chemical plant technology such as fluid systems and chemical reactor systems. Some would consider an oil refinery or a pharmaceutical or polymer manufacturer to be effectively a chemical plant.

High-density polyethylene (HDPE) or polyethylene high-density (PEHD) is a thermoplastic polymer produced from the monomer ethylene. It is sometimes called "alkathene" or "polythene" when used for HDPE pipes. With a high strength-to-density ratio, HDPE is used in the production of plastic bottles, corrosion-resistant piping, geomembranes and plastic lumber. HDPE is commonly recycled, and has the number "2" as its resin identification code.

Cross-linked polyethylene, commonly abbreviated PEX, XPE or XLPE, is a form of polyethylene with cross-links. It is used predominantly in building services pipework systems, hydronic radiant heating and cooling systems, domestic water piping, insulation for high tension electrical cables, and baby play mats. It is also used for natural gas and offshore oil applications, chemical transportation, and transportation of sewage and slurries. PEX is an alternative to polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC) or copper tubing for use as residential water pipes.

Electric heat tracing, heat tape or surface heating, is a system used to maintain or raise the temperature of pipes and vessels using heat tracing cables. Trace heating takes the form of an electrical heating element run in physical contact along the length of a pipe. The pipe is usually covered with thermal insulation to retain heat losses from the pipe. Heat generated by the element then maintains the temperature of the pipe. Trace heating may be used to protect pipes from freezing, to maintain a constant flow temperature in hot water systems, or to maintain process temperatures for piping that must transport substances that solidify at ambient temperatures. Electric trace heating cables are an alternative to steam trace heating where steam is unavailable or unwanted.

A pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases (fluids), slurries, powders and masses of small solids. It can also be used for structural applications; hollow pipe is far stiffer per unit weight than solid members.

A fitting or adapter is used in pipe systems to connect sections of pipe or tube, adapt to different sizes or shapes, and for other purposes such as regulating fluid flow. These fittings are used in plumbing to manipulate the conveyance of fluids such as water for potatory, irrigational, sanitary, and refrigerative purposes, gas, petroleum, liquid waste, or any other liquid or gaseous substances required in domestic or commercial environments, within a system of pipes or tubes, connected by various methods, as dictated by the material of which these are made, the material being conveyed, and the particular environmental context in which they will be used, such as soldering, mortaring, caulking, Plastic welding, welding, friction fittings, threaded fittings, and compression fittings.

A pipefitter or steamfitter is a tradesman who installs, assembles, fabricates, maintains, and repairs mechanical piping systems. Pipefitters usually begin as helpers or apprentices. Journeyman pipefitters deal with industrial/commercial/marine piping and heating/cooling systems. Typical industrial process pipe is under high pressure, which requires metals such as carbon steel, stainless steel, and many different alloy metals fused together through precise cutting, threading, grooving, bending, and welding. A plumber concentrates on lower pressure piping systems for sewage and potable tap water in the industrial, commercial, institutional, or residential atmosphere. Utility piping typically consists of copper, PVC, CPVC, polyethylene, and galvanized pipe, which is typically glued, soldered, or threaded. Other types of piping systems include steam, ventilation, hydraulics, chemicals, fuel, and oil.

The Meillerwagen was a German World War II trailer used to transport a V-2 rocket from the 'transloading point' of the Technical Troop Area to the launching point, to erect the missile on the Brennstand, and to act as the service gantry for fuelling and launch preparation.

A fan coil unit (FCU), also known as a Vertical Fan Coil-Unit (VFC), is a device consisting of a heat exchanger (coil) and a fan. FCUs are commonly used in HVAC systems of residential, commercial, and industrial buildings that use ducted split air conditioning or with central plant cooling. FCUs are typically connected to ductwork and a thermostat to regulate the temperature of one or more spaces and to assist the main air handling unit for each space if used with chillers. The thermostat controls the fan speed and/or the flow of water or refrigerant to the heat exchanger using a control valve.

Black powder is an industry name for the abrasive, reactive particulate contamination present in all gas and hydrocarbon fluid transmission lines. Black powder ranges from light brown to black, and the mineral makeup varies per production field around the world.

Plastic pipe is a tubular section, or hollow cylinder, made of plastic. It is usually, but not necessarily, of circular cross-section, used mainly to convey substances which can flow—liquids and gases (fluids), slurries, powders and masses of small solids. It can also be used for structural applications; hollow pipes are far stiffer per unit weight than solid members.

Heat fusion is a welding process used to join two different pieces of a thermoplastic. This process involves heating both pieces simultaneously and pressing them together. The two pieces then cool together and form a permanent bond. When done properly, the two pieces become indistinguishable from each other. Dissimilar plastics can result in improper bonding.

In the process industry, chemical industry, manufacturing industry, and other commercial and industrial contexts, pipe marking is used to identify the contents, properties and flow direction of fluids in piping. It is typically carried out by marking piping through labels and color codes. Pipe marking helps personnel and fire response teams identify the correct pipes for operational, maintenance or emergency response purposes.

HDPE pipe is a type of flexible plastic pipe used to transfer fluids and gases. It is often employed for replacing aging concrete or steel main pipelines. Constructed from the thermoplastic HDPE, it has low permeability and robust molecular bonding, making it suitable for high-pressure pipelines. HDPE pipe is often used for water mains, gas mains, sewer mains, slurry transfer lines, rural irrigation, fire-suppression system supply lines, electrical and communication conduits, and stormwater and drainage pipes.

A water distribution system is a part of water supply network with components that carry potable water from a centralized treatment plant or wells to consumers to satisfy residential, commercial, industrial and fire fighting requirements.

References

- 1 2 Drake, Richard M., P.E., S.E., SECB and Walter, Robert J., P.E., S.E. "Seismic Design of Structural Steel Pipe Racks". Structure Magazine. February 2012.

- ↑ Bausbacher, Ed (1993). Process Plant Layout and Piping Design. New Jersey: PTR Prentice-Hall, inc. p. 261. ISBN 0-13-138629-8.

- ↑ Translated from: "piping een vak apart" Zadkine Contract Activiteiten bv/ Technology Consultancy Centre 2001, first edition.