An assembly line is a manufacturing process in which parts are added as the semi-finished assembly moves from workstation to workstation where the parts are added in sequence until the final assembly is produced. By mechanically moving the parts to the assembly work and moving the semi-finished assembly from work station to work station, a finished product can be assembled faster and with less labor than by having workers carry parts to a stationary piece for assembly.

Mass production, also known as flow production, series production, series manufacture, or continuous production, is the production of substantial amounts of standardized products in a constant flow, including and especially on assembly lines. Together with job production and batch production, it is one of the three main production methods.

The Ford Model T is an automobile that was produced by the Ford Motor Company from October 1, 1908, to May 26, 1927. It is generally regarded as the first mass-affordable automobile, which made car travel available to middle-class Americans. The relatively low price was partly the result of Ford's efficient fabrication, including assembly line production instead of individual handcrafting. The savings from mass production allowed the price to decline from $780 in 1910 to $290 in 1924. It was mainly designed by three engineers, Joseph A. Galamb, Eugene Farkas, and Childe Harold Wills. The Model T was colloquially known as the "Tin Lizzie".

A factory, manufacturing plant or production plant is an industrial facility, often a complex consisting of several buildings filled with machinery, where workers manufacture items or operate machines which process each item into another. They are a critical part of modern economic production, with the majority of the world's goods being created or processed within factories.

The Continental Mark II is an ultra-luxury coupé that was sold by the Continental Division of Ford for the 1956 and 1957 model years. The first product line of Continental, the Mark II was developed as the worldwide flagship vehicle of Ford Motor Company. Developed as a successor for the 1939–1948 Lincoln Continental, the Mark II derived its nameplate from European manufacturing practice, denoting a second generation of the model family; Ford would later use this nomenclature for the Mark Series of flagship personal luxury cars.

A car platform is a shared set of common design, engineering, and production efforts, as well as major components, over a number of outwardly distinct models and even types of cars, often from different, but somewhat related, marques. It is practiced in the automotive industry to reduce the costs associated with the development of products by basing those products on a smaller number of platforms. This further allows companies to create distinct models from a design perspective on similar underpinnings. A car platform is not to be confused with a platform chassis, although such a chassis can be part of an automobile's design platform, as noted below.

The Ford Panther platform was an automobile platform that was used by Ford Motor Company from the 1979 to 2012 model years. Following the downsizing of the General Motors B-bodies and C-bodies by two years, the Panther platform marked the end of production of sedans unencumbered by downsizing. Originally slated for discontinuation during the early 1980s, the Panther architecture was used for 33 model years, making it one of the longest-produced platforms in North American automotive history.

The Ford E-Series is a range of full-size vans manufactured and marketed by the Ford Motor Company. Introduced for 1961 as the replacement of the Ford F-Series panel van, four generations of the model line have been produced. Marketed for both cargo and passenger transport configurations, the E-Series has been designed with multiple design variations for both retail and commercial sale, including vans, and commercial-grade cutaway van chassis and stripped chassis.

The Highland Park Ford Plant is a former Ford Motor Company factory located at 91 Manchester Street in Highland Park, Michigan. It was the second American production facility for the Model T automobile and the first factory in history to assemble cars on a moving assembly line. It became a National Historic Landmark in 1978.

Thomas Built Buses, Inc. is an American bus manufacturer. Best known for its production of the first ever rear engine Type C school bus. Thomas produces other bus designs for a variety of usages. Currently, its production is concentrated on school buses and activity buses, along with their commercial derivatives.

Space manufacturing or In-space manufacturing is the fabrication, assembly or integration of tangible goods beyond Earth's atmosphere, involving the transformation of raw or recycled materials into components, products, or infrastructure in space, where the manufacturing process is executed either by humans or automated systems by taking advantage of the unique characteristics of space. Synonyms of Space/In-space manufacturing are In-orbit manufacturing, Off-Earth manufacturing, Space-based manufacturing, Orbital manufacturing, In-situ manufacturing, In-space fabrication, In-space production, etc.

Operations management is concerned with designing and controlling the production of goods and services, ensuring that businesses are efficient in using resources to meet customer requirements.

A conveyor system is a common piece of mechanical handling equipment that moves materials from one location to another. Conveyors are especially useful in applications involving the transport of heavy or bulky materials. Conveyor systems allow quick and efficient transport for a wide variety of materials, which make them very popular in the material handling and packaging industries. They also have popular consumer applications, as they are often found in supermarkets and airports, constituting the final leg of item/ bag delivery to customers. Many kinds of conveying systems are available and are used according to the various needs of different industries. There are chain conveyors as well. Chain conveyors consist of enclosed tracks, I-Beam, towline, power & free, and hand pushed trolleys.

The Ford Ranger is a compact or mid-size pickup marketed globally by Ford over a series of generations, varying between both in-house or outside development and manufacturing — and with a hiatus in North America from 2011–2018.

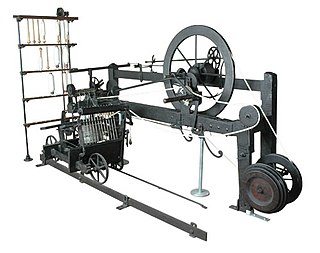

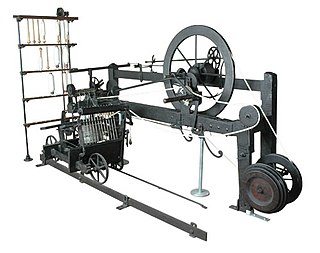

The productivity-improving technologies are the technological innovations that have historically increased productivity.

Pay on production (PoP) is a special build-operate-transfer (BOT) model, where payment is made to a supplier by the original equipment manufacturer (OEM) per piece produced on the supplier's own equipment by the OEM's employees.

The automotive industry in New Zealand supplies a market which has always had one of the world's highest car ownership ratios. The distributors of new cars are essentially the former owners of the assembly businesses. At the dealership level they have maintained their old retail chains in spite of the establishment of the many new independent businesses built since the 1980s by specialists in used imports from Japan. Toyota entered into direct competition with those used-import businesses refurbishing old Toyotas from Japan and selling them through their own dealers as a special line. The nation's car fleet is accordingly somewhat older than in most developed countries.

The Ford Southampton plant was a motor vehicle assembly plant, located in Swaythling on the north eastern outskirts of Southampton, England. It was the western European centre for production of the Ford Transit van. The last vehicle was produced on 26 July 2013, ending Ford's vehicle assembly operations in the UK.

The Cassino Assembly Plant is a car assembly plant owned by Stellantis. It is located in the town of Piedimonte San Germano, three kilometers from Cassino, in the province of Frosinone, Italy. The car assembly plant started in 1972 with the production of Fiat 126. Today, it has a total surface area of 2 million square meters, of which 400 thousand are covered. The plant currently employs around 4,300 people.

Thames was a commercial vehicle brand produced by Ford of Britain.