An anti-lock braking system (ABS) is a safety anti-skid braking system used on aircraft and on land vehicles, such as cars, motorcycles, trucks, and buses. ABS operates by preventing the wheels from locking up during braking, thereby maintaining tractive contact with the road surface and allowing the driver to maintain more control over the vehicle.

A drum brake is a brake that uses friction caused by a set of shoes or pads that press outward against a rotating bowl-shaped part called a brake drum.

A shock absorber or damper is a mechanical or hydraulic device designed to absorb and damp shock impulses. It does this by converting the kinetic energy of the shock into another form of energy which is then dissipated. Most shock absorbers are a form of dashpot.

A railway air brake is a railway brake power braking system with compressed air as the operating medium. Modern trains rely upon a fail-safe air brake system that is based upon a design patented by George Westinghouse on April 13, 1869. The Westinghouse Air Brake Company was subsequently organized to manufacture and sell Westinghouse's invention. In various forms, it has been nearly universally adopted.

Suspension is the system of tires, tire air, springs, shock absorbers and linkages that connects a vehicle to its wheels and allows relative motion between the two. Suspension systems must support both road holding/handling and ride quality, which are at odds with each other. The tuning of suspensions involves finding the right compromise. It is important for the suspension to keep the road wheel in contact with the road surface as much as possible, because all the road or ground forces acting on the vehicle do so through the contact patches of the tires. The suspension also protects the vehicle itself and any cargo or luggage from damage and wear. The design of front and rear suspension of a car may be different.

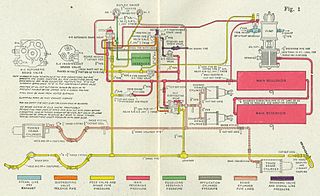

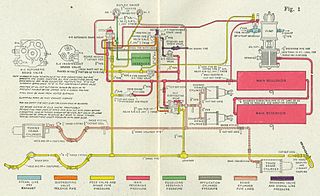

Hydropneumatic suspension is a type of motor vehicle suspension system, designed by Paul Magès, invented by Citroën, and fitted to Citroën cars, as well as being used under licence by other car manufacturers, notably Rolls-Royce, Bmw 5-Series e34 Touring, Maserati and Peugeot. It was also used on Berliet trucks and has been used on Mercedes-Benz cars, where it is known as Active Body Control. The Toyota Soarer UZZ32 "Limited" was fitted with a fully integrated four-wheel steering and a complex, computer-controlled hydraulic Toyota Active Control Suspension in 1991. Similar systems are also widely used on modern tanks and other large military vehicles. The suspension was referred to as fr:Suspension oléopneumatique in early literature, pointing to oil and air as its main components.

Electronic brakeforce distribution or electronic brakeforce limitation (EBL) is an automobile brake technology that automatically varies the amount of force applied to each of a vehicle's wheels, based on road conditions, speed, loading, etc, thus providing intelligent control of both brake balance and overall brake force. Always coupled with anti-lock braking systems (ABS), EBD can apply more or less braking pressure to each wheel in order to maximize stopping power whilst maintaining vehicular control. Typically, the front end carries more weight and EBD distributes less braking pressure to the rear brakes so the rear brakes do not lock up and cause a skid. In some systems, EBD distributes more braking pressure at the rear brakes during initial brake application before the effects of weight transfer become apparent.

Hydraulic machines use liquid fluid power to perform work. Heavy construction vehicles are a common example. In this type of machine, hydraulic fluid is pumped to various hydraulic motors and hydraulic cylinders throughout the machine and becomes pressurized according to the resistance present. The fluid is controlled directly or automatically by control valves and distributed through hoses, tubes, or pipes.

A relay valve is an air-operated valve typically used in air brake systems to remotely control the brakes at the rear of a heavy truck or semi-trailer in a tractor-trailer combination. Relay valves are necessary in heavy trucks in order to speed-up rear-brake application and release, since air takes longer to travel to the rear of the vehicle than the front of the vehicle, where the front service brakes, foot-valve, parking-control valve, and trailer-supply valve are located.

Brake bleeding is the procedure performed on hydraulic brake systems whereby the brake lines are purged of any air bubbles. This is necessary because, while the brake fluid is an incompressible liquid, air bubbles are compressible gas and their presence in the brake system greatly reduces the hydraulic pressure that can be developed within the system. The same methods used for bleeding are also used for brake flushing or purging, where the old fluid is replaced with new fluid, which is necessary maintenance.

A hydraulic brake is an arrangement of braking mechanism which uses brake fluid, typically containing glycol ethers or diethylene glycol, to transfer pressure from the controlling mechanism to the braking mechanism.

DIRAVI is the name given by Citroën to its proprietary power steering system, first seen in 1970.

Self-levelling refers to an automobile suspension system that maintains a constant ride height of the vehicle above the road, regardless of load.

A motorcycle's suspension serves a dual purpose: contributing to the vehicle's handling and braking, and providing safety and comfort by keeping the vehicle's passengers comfortably isolated from road noise, bumps and vibrations.

An air brake or, more formally, a compressed-air-brake system, is a type of friction brake for vehicles in which compressed air pressing on a piston is used to both release the parking/emergency brakes in order to move the vehicle, and also to apply pressure to the brake pads or brake shoes to slow and stop the vehicle. Air brakes are used in large heavy vehicles, particularly those having multiple trailers which must be linked into the brake system, such as trucks, buses, trailers, and semi-trailers, in addition to their use in railroad trains. George Westinghouse first developed air brakes for use in railway service. He patented a safer air brake on March 5, 1872. Westinghouse made numerous alterations to improve his air pressured brake invention, which led to various forms of the automatic brake. In the early 20th century, after its advantages were proven in railway use, it was adopted by manufacturers of trucks and heavy road vehicles.

Subaru launched the third generation Japanese and world-market Legacy in June 1998, while the North American model was introduced in May 1999 for the 2000 model year. In all markets except for the United States, production lasted through 2002, with a limited production Blitzen model sold mid-cycle under the 2003 model year in Japan. Production in the United States lasted through 2004.

A combined braking system (CBS), also called linked braking system (LBS), is a system for linking front and rear brakes on a motorcycle or scooter. In this system, the rider's action of depressing one of the brake levers applies both front and rear brakes. The amount of each brake applied may be determined by a proportional control valve. This is distinct from (conventional) integrated brakes, where applying pressure to the rear brake pedal only applies some braking force to the front brake.

The General Motors front-wheel drive X platform was used for compact cars from the 1980 through 1985 model years, superseding the earlier, similarly designated, rear-drive platform.

The brake balance or brake bias of a vehicle is the distribution of brake force at the front and rear tires, and may be given as the percentage distributed to the front brakes or as the ratio of front and rear percentages. The braking balance affects the driving characteristics in terms of how fast the vehicle can brake, how the vehicle can take corners, and tire wear. The optimal brake balance can vary between circuits, weather conditions and driving styles. On race cars, the brake balance is often part of the racing setup, and in formula car racing it is regularly adjusted during the course of an entire lap. In some cases, the brake balance may be adjusted to match the traction (grip) of the vehicle during braking, which usually means distributing a greater braking force to the front. In other cases, it may be desirable for the brake balance to be the more similar at the front and rear for the tires to last longer, which may be beneficial in endurance racing. Adjustment of the brake balance is often done by adjusting a proportioning valve which determines the distribution of the brake force between the front and rear brakes. The adjustment can be made via mechanical couplings or with the help of a small electric motor.