The topic of this article may not meet Wikipedia's notability guidelines for products and services .(March 2023) |

Prusa Mini+ Black Edition | |

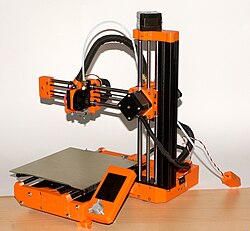

| Classification | Fused deposition modeling 3D printer |

|---|---|

| Inventor | Josef Průša |

| Manufacturer | Prusa Research |

The Prusa Mini, stylized as the Original Prusa MINI, is an open-source fused deposition modeling 3D printer that is manufactured by the Czech company Prusa Research. [1] [2] The printer is the lowest cost machine produced by Prusa Research and is designed as a first printer or as part of a 'print farm'. [1] [3] [4]