This article has multiple issues. Please help improve it or discuss these issues on the talk page . (Learn how and when to remove these template messages)

|

Pulverized coal injection is a method for improving the performance of a blast furnace. [1]

This article has multiple issues. Please help improve it or discuss these issues on the talk page . (Learn how and when to remove these template messages)

|

Pulverized coal injection is a method for improving the performance of a blast furnace. [1]

Iron is a metal that has fundamentally affected the way of life of human beings ever since the Iron Age. It is relatively abundant and can easily be extracted and modified due to its useful material properties, all of which result in low prices. After the Industrial Revolution (18-19th century), iron became a core material of industrial markets, its importance reflected in the phrase “iron is nation”; its production was directly regarded as an indication of national power. Especially after World War II, governments vigorously supported the growth of an iron industrial market, which significantly contributed to the development of a global economy. Iron is extracted from its ore and smelted in a metallurgical furnace called a "blast furnace".

The blast furnace method is expected to survive into the 22nd century because of its efficient rate of iron production at competitive costs compared with other iron-making methods. Blast furnaces keep on improving with adaptations arising from new technologies driven by rising global demand, yet the main chemical process remains the same. But process improvement cannot solve many of the problems associated with blast furnaces. The rate of iron production is highly influenced by fluctuations in the world economy, and improving the operational efficiency of the process is of major concern. However, the biggest drawback of blast furnace operation is the inevitable carbon dioxide production from iron reduction processes, which is considered one of the major contributors in global warming. Accordingly, the Pulverized Coal Injection (PCI) method is becoming an internationally popular method for improving blast furnace operation.

Pulverized coal injection was developed in the 19th century, but was not implemented industrially until the 1970s. Rises in the cost of coke due to increased global demand and thus more competition for the resource have made this method attractive to the iron-producing industries and increased its value.

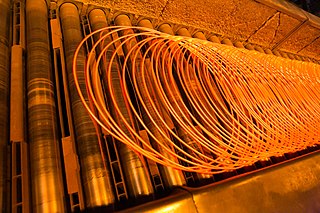

The PCI method is based on the simple concept of primary air (termed the "conveying gas") carrying pulverized coal which injected through a lance to the tuyere (mid-bottom inlet of a blast furnace), then mixed with secondary hot air (termed the "blast") supplied through a blowpipe in the tuyere and then piped to a furnace to create a balloon-like cavity called a "raceway", which then propagates coal and coke combustion and melts the solid iron ore, releasing molten iron. The most remarkable aspect of this method is that it allows for cheaper coal to be consumed in the system, replace expensive coke, thereby remarkably cutting down on costs. Because of the extreme heat inside the furnace (>2000 Kelvin), visual observation of raceway shape and size is impossible, so remotely measuring sensors are used to investigate the chemical and physical reactions inside the furnace.

Better understanding of the raceway and PCI method can optimize the performance of a blast furnace and reduce costs. Further improvements to the PCI method and the use of coal blend (mixing different coals) injection methods are attracting industry.

Coke is a grey, hard, and porous coal-based fuel with a high carbon content. It is made by heating coal or oil in the absence of air. Coke is an important industrial product, used mainly in iron ore smelting, but also as a fuel in stoves and forges.

Steelmaking is the process of producing steel from iron ore and/or scrap. In steelmaking, impurities such as nitrogen, silicon, phosphorus, sulfur and excess carbon are removed from the sourced iron, and alloying elements such as manganese, nickel, chromium, carbon and vanadium are added to produce different grades of steel.

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. Blast refers to the combustion air being supplied above atmospheric pressure.

Industrial processes are procedures involving chemical, physical, electrical, or mechanical steps to aid in the manufacturing of an item or items, usually carried out on a very large scale. Industrial processes are the key components of heavy industry.

A steel mill or steelworks is an industrial plant for the manufacture of steel. It may be an integrated steel works carrying out all steps of steelmaking from smelting iron ore to rolled product, but may also be a plant where steel semi-finished casting products are made from molten pig iron or from scrap.

Direct reduced iron (DRI), also called sponge iron, is produced from the direct reduction of iron ore into iron by a reducing gas which contains elemental carbon and/or hydrogen. When hydrogen is used as the reducing gas there are no greenhouse gases produced. Many ores are suitable for direct reduction.

ArcelorMittal Kryvyi Rih is Ukraine's largest integrated steel company, founded in 1934 and located in Kryvyi Rih, in central Ukraine.

FINEX is the name for an iron making technology developed by former Siemens VAI and POSCO. Molten iron is produced directly using iron ore fines and non-coking coal rather than traditional blast furnace methods through sintering and reduction with coke. Elimination of preliminary processing is claimed to make the plant for FINEX less expensive to build than a blast furnace facility of the same scale, additionally a 10-15% reduction in production costs is expected/claimed through cheaper raw materials, reduction of facility cost, pollutant exhaustion, maintenance staff and production time. The process is claimed to produce less pollutants such as SOx, NOx, and carbon dioxide than traditional methods.

Hot blast refers to the preheating of air blown into a blast furnace or other metallurgical process. As this considerably reduced the fuel consumed, hot blast was one of the most important technologies developed during the Industrial Revolution. Hot blast also allowed higher furnace temperatures, which increased the capacity of furnaces.

A Walloon forge is a type of finery forge that decarbonizes pig iron into wrought iron.

Cornwall Iron Furnace is a designated National Historic Landmark that is administered by the Pennsylvania Historical and Museum Commission in Cornwall, Lebanon County, Pennsylvania in the United States. The furnace was a leading Pennsylvania iron producer from 1742 until it was shut down in 1883. The furnaces, support buildings and surrounding community have been preserved as a historical site and museum, providing a glimpse into Lebanon County's industrial past. The site is the only intact charcoal-burning iron blast furnace in its original plantation in the western hemisphere. Established by Peter Grubb in 1742, Cornwall Furnace was operated during the Revolution by his sons Curtis and Peter Jr. who were major arms providers to George Washington. Robert Coleman acquired Cornwall Furnace after the Revolution and became Pennsylvania's first millionaire. Ownership of the furnace and its surroundings was transferred to the Commonwealth of Pennsylvania in 1932.

A cupola or cupola furnace is a melting device used in foundries that can be used to melt cast iron, Ni-resist iron and some bronzes. The cupola can be made almost any practical size. The size of a cupola is expressed in diameters and can range from 1.5 to 13 feet. The overall shape is cylindrical and the equipment is arranged vertically, usually supported by four legs. The overall look is similar to a large smokestack.

Zinc smelting is the process of converting zinc concentrates into pure zinc. Zinc smelting has historically been more difficult than the smelting of other metals, e.g. iron, because in contrast, zinc has a low boiling point. At temperatures typically used for smelting metals, zinc is a gas that will escape from a furnace with the flue gas and be lost, unless specific measures are taken to prevent it.

The HIsarna ironmaking process is a direct reduced iron process for iron making in which iron ore is processed almost directly into liquid iron (pig iron). The process combines two process units, the Cyclone Converter Furnace (CCF) for ore melting and pre-reduction and a Smelting Reduction Vessel (SRV) where the final reduction stage to liquid iron takes place. The process does not require the manufacturing of iron ore agglomerates such as pellets and sinter, nor the production of coke, which are necessary for the blast furnace process. Without these steps, the HIsarna process is more energy-efficient and has a lower carbon footprint than traditional ironmaking processes. In 2018 Tata Steel announced it has demonstrated that more than 50% CO2 emission reduction is possible with HIsarna technology, without the need for carbon capture technology.

Kemondo Iron Age Sites or KM2 and KM3 are Early Iron Age complex industrial archaeological sites in Kemondo ward, Bukoba Rural District, Kagera Region, Tanzania, excavated by a team led by archaeologist Peter Schmid in the late 1970s and 1980s. The excavations aimed at better understanding the iron smelting process and its ritual aspects in East Africa. At the KM2 and KM3 sites, Schmidt tested the hypothesis that the high combustion temperature of furnaces, discovered to be between 1,350–1,400 °C (2,460–2,550 °F), was caused by the preheating of air blasts. Preheating has been suggested to be a distinct feature of African Early Iron Age smelting techniques by ethnographic observations of the Haya people of northwestern Tanzania.

Metallurgical coal or coking coal is a grade of coal that can be used to produce good-quality coke. Coke is an essential fuel and reactant in the blast furnace process for primary steelmaking. The demand for metallurgical coal is highly coupled to the demand for steel. Primary steelmaking companies often have a division that produces coal for coking, to ensure a stable and low-cost supply.

Adrien C. B. Chenot was a French engineer best known for his inventions in metallurgy as well as his research on manufactured gases. He is notably the inventor of one of the first modern methods of direct reduction of iron ore, based on the use of coal reacting with the ore in retorts. He exhibited the first samples of pre-reduced iron ore at the Lisbon Universal Exhibition of 1849, and was awarded the "Grandes Medailles d'Or" at the Paris Universal Exposition of 1855.

In the iron and steel industry, direct reduction is a set of processes for obtaining iron from iron ore, by reducing iron oxides without melting the metal. The resulting product is pre-reduced iron ore.

The Krupp–Renn process was a direct reduction steelmaking process used from the 1930s to the 1970s. It used a rotary furnace and was one of the few technically and commercially successful direct reduction processes in the world, acting as an alternative to blast furnaces due to their coke consumption. The Krupp-Renn process consumed mainly hard coal and had the unique characteristic of partially melting the charge. This method is beneficial for processing low-quality or non-melting ores, as their waste material forms a protective layer that can be easily separated from the iron. It generates Luppen, nodules of pre-reduced iron ore, which can be easily melted down.

Magnetic roasting technology refers to the process of heating materials or ores under specific atmospheric conditions to induce chemical reactions. This process selectively converts weakly magnetic iron minerals such as hematite (Fe2O3), siderite (FeCO3), and limonite (Fe2O3·nH2O) into strongly magnetic magnetite (Fe3O4) or maghemite (γ-Fe2O3), while the magnetic properties of gangue minerals remain almost unchanged.