Pyrolytic coating is a thin film coating applied at high temperatures and sprayed onto the glass surface during the float glass process.

Pyrolytic coating is a thin film coating applied at high temperatures and sprayed onto the glass surface during the float glass process.

Pyrolytic coating can be used as a protective or decorative coating on equipment parts, energy-insulator on window glasses, anti-friction agent in moulding applications.

Cast iron is a class of iron–carbon alloys with a carbon content of more than 2% and silicon content around 1–3%. Its usefulness derives from its relatively low melting temperature. The alloying elements determine the form in which its carbon appears: white cast iron has its carbon combined into an iron carbide named cementite, which is very hard, but brittle, as it allows cracks to pass straight through; grey cast iron has graphite flakes which deflect a passing crack and initiate countless new cracks as the material breaks, and ductile cast iron has spherical graphite "nodules" which stop the crack from further progressing.

The pebble-bed reactor (PBR) is a design for a graphite-moderated, gas-cooled nuclear reactor. It is a type of very-high-temperature reactor (VHTR), one of the six classes of nuclear reactors in the Generation IV initiative.

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials by chemical or electrochemical reaction with their environment. Corrosion engineering is the field dedicated to controlling and preventing corrosion.

Chrome plating is a technique of electroplating a thin layer of chromium onto a metal object. A chrome plated part is called chrome, or is said to have been chromed. The chromium layer can be decorative, provide corrosion resistance, facilitate cleaning, and increase surface hardness. Sometimes, a less expensive substitute for chrome such as nickel may be used for aesthetic purposes.

Tungsten carbide is a chemical compound containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten carbide is a fine gray powder, but it can be pressed and formed into shapes through sintering for use in industrial machinery, cutting tools, chisels, abrasives, armor-piercing shells and jewelry.

A cermet is a composite material composed of ceramic and metal materials.

In materials science, a refractory is a material that is resistant to decomposition by heat or chemical attack that retains its strength and rigidity at high temperatures. They are inorganic, non-metallic compounds that may be porous or non-porous, and their crystallinity varies widely: they may be crystalline, polycrystalline, amorphous, or composite. They are typically composed of oxides, carbides or nitrides of the following elements: silicon, aluminium, magnesium, calcium, boron, chromium and zirconium. Many refractories are ceramics, but some such as graphite are not, and some ceramics such as clay pottery are not considered refractory. Refractories are distinguished from the refractory metals, which are elemental metals and their alloys that have high melting temperatures.

Plating is a finishing process in which a metal is deposited on a surface. Plating has been done for hundreds of years; it is also critical for modern technology. Plating is used to decorate objects, for corrosion inhibition, to improve solderability, to harden, to improve wearability, to reduce friction, to improve paint adhesion, to alter conductivity, to improve IR reflectivity, for radiation shielding, and for other purposes. Jewelry typically uses plating to give a silver or gold finish.

Titanium nitride is an extremely hard ceramic material, often used as a physical vapor deposition (PVD) coating on titanium alloys, steel, carbide, and aluminium components to improve the substrate's surface properties.

Pyrolytic carbon is a material similar to graphite, but with some covalent bonding between its graphene sheets as a result of imperfections in its production.

A superalloy, or high-performance alloy, is an alloy with the ability to operate at a high fraction of its melting point. Key characteristics of a superalloy include mechanical strength, thermal creep deformation resistance, surface stability, and corrosion and oxidation resistance.

Low emissivity refers to a surface condition that emits low levels of radiant thermal (heat) energy. All materials absorb, reflect, and emit radiant energy according to Planck's law but here, the primary concern is a special wavelength interval of radiant energy, namely thermal radiation of materials. In common use, especially building applications, the temperature range of approximately -40 to +80 degrees Celsius is the focus, but in aerospace and industrial process engineering, much broader ranges are of practical concern.

Chromium(II) carbide is a ceramic compound that exists in several chemical compositions: Cr3C2, Cr7C3, and Cr23C6. At standard conditions it exists as a gray solid. It is extremely hard and corrosion resistant. It is also a refractory compound, which means that it retains its strength at high temperatures as well. These properties make it useful as an additive to metal alloys. When chromium carbide crystals are integrated into the surface of a metal it improves the wear resistance and corrosion resistance of the metal, and maintains these properties at elevated temperatures. The hardest and most commonly used composition for this purpose is Cr3C2.

Physical vapor deposition (PVD), sometimes called physical vapor transport (PVT), describes a variety of vacuum deposition methods which can be used to produce thin films and coatings on substrates including metals, ceramics, glass, and polymers. PVD is characterized by a process in which the material transitions from a condensed phase to a vapor phase and then back to a thin film condensed phase. The most common PVD processes are sputtering and evaporation. PVD is used in the manufacturing of items which require thin films for optical, mechanical, electrical, acoustic or chemical functions. Examples include semiconductor devices such as thin-film solar cells, microelectromechanical devices such as thin film bulk acoustic resonator, aluminized PET film for food packaging and balloons, and titanium nitride coated cutting tools for metalworking. Besides PVD tools for fabrication, special smaller tools used mainly for scientific purposes have been developed.

A self-cleaning or pyrolytic oven is an oven which uses high temperature to burn off leftovers from baking, without the use of any chemical agents. The oven can be powered by domestic (non-commercial) electricity or gas.

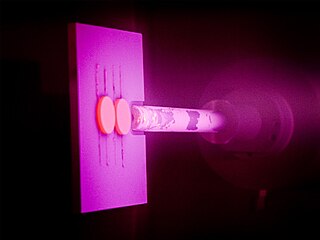

Pyrolytic chromium carbide coating (PCC) is a technology for protection and reworking of rapidly wearing parts of manufacturing equipment working in extreme environmental conditions, using vacuum deposition technology. Coating mechanical parts can help with problems of corrosion, adhering, high-temperature and mechanical wear thus reducing unplanned repairs and loss of production.

Cemented carbides are a class of hard materials used extensively for cutting tools, as well as in other industrial applications. It consists of fine particles of carbide cemented into a composite by a binder metal. Cemented carbides commonly use tungsten carbide (WC), titanium carbide (TiC), or tantalum carbide (TaC) as the aggregate. Mentions of "carbide" or "tungsten carbide" in industrial contexts usually refer to these cemented composites.

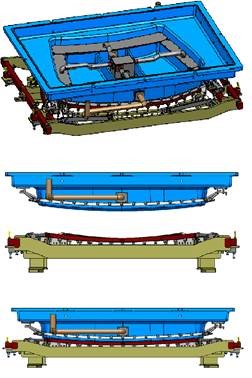

Precision glass moulding is a replicative process that allows the production of high precision optical components from glass without grinding and polishing. The process is also known as ultra-precision glass pressing. It is used to manufacture precision glass lenses for consumer products such as digital cameras, and high-end products like medical systems. The main advantage over mechanical lens production is that complex lens geometries such as aspheres can be produced cost-efficiently.

Detonation spraying is one of the many forms of thermal spraying techniques that are used to apply a protective coating at supersonic velocities to a material in order to change its surface characteristics. This is primarily to improve the durability of a component. It was first invented in 1955 by H.B. Sargent, R.M. Poorman and H. Lamprey and is applied to a component using a specifically designed detonation gun (D-gun). The component being sprayed must be prepared correctly by removing all surface oils, greases, debris and roughing up the surface in order to achieve a strongly bonded detonation spray coating. This process involves the highest velocities and temperatures (≈4000 °C) of coating materials compared to all other forms of thermal spraying techniques. Which means detonation spraying is able to apply low porous and low oxygen content protective coatings that protect against corrosion, abrasion and adhesion under low load.