Related Research Articles

Rebar, known when massed as reinforcing steel or reinforcement steel, is a steel bar used as a tension device in reinforced concrete and reinforced masonry structures to strengthen and aid the concrete under tension. Concrete is strong under compression, but has low tensile strength. Rebar significantly increases the tensile strength of the structure. Rebar's surface features a continuous series of ribs, lugs or indentations to promote a better bond with the concrete and reduce the risk of slippage.

A rivet is a permanent mechanical fastener. Before being installed, a rivet consists of a smooth cylindrical shaft with a head on one end. The end opposite the head is called the tail. On installation, the rivet is placed in a punched or drilled hole, and the tail is upset or bucked, so that it expands to about 1.5 times the original shaft diameter, holding the rivet in place. In other words, the pounding or pulling creates a new "head" on the tail end by smashing the "tail" material flatter, resulting in a rivet that is roughly a dumbbell shape. To distinguish between the two ends of the rivet, the original head is called the factory head and the deformed end is called the shop head or buck-tail.

Seismic retrofitting is the modification of existing structures to make them more resistant to seismic activity, ground motion, or soil failure due to earthquakes. With better understanding of seismic demand on structures and with our recent experiences with large earthquakes near urban centers, the need of seismic retrofitting is well acknowledged. Prior to the introduction of modern seismic codes in the late 1960s for developed countries and late 1970s for many other parts of the world, many structures were designed without adequate detailing and reinforcement for seismic protection. In view of the imminent problem, various research work has been carried out. State-of-the-art technical guidelines for seismic assessment, retrofit and rehabilitation have been published around the world – such as the ASCE-SEI 41 and the New Zealand Society for Earthquake Engineering (NZSEE)'s guidelines. These codes must be regularly updated; the 1994 Northridge earthquake brought to light the brittleness of welded steel frames, for example.

A concrete block, also known as a cinder block in North American English, breeze block in British English, concrete masonry unit (CMU), or by various other terms, is a standard-size rectangular block used in building construction. The use of blockwork allows structures to be built in the traditional masonry style with layers of staggered blocks.

Structural steel is a category of steel used for making construction materials in a variety of shapes. Many structural steel shapes take the form of an elongated beam having a profile of a specific cross section. Structural steel shapes, sizes, chemical composition, mechanical properties such as strengths, storage practices, etc., are regulated by standards in most industrialized countries.

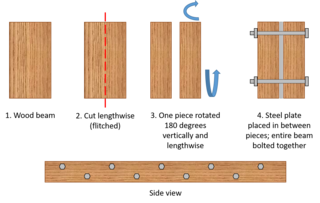

A flitch beam is a compound beam used in the construction of houses, decks, and other primarily wood-frame structures. Typically, the flitch beam is made up of a vertical steel plate sandwiched between two wood beams, the three layers being held together with bolts. In that common form it is sometimes referenced as a steel flitch beam. Further alternating layers of wood and steel can be used to produce an even stronger beam. The metal plates within the beam are known as flitch plates.[1] Flitch beams were used as a cost-effective way to strengthen long-span wooden beams, and have been largely supplanted by more recent technology.

A36 steel is a common structural steel alloy utilized in the United States. The A36 standard was established by the ASTM International. The standard was published in 1960 and has been updated several times since. Prior to 1960, the dominant standards for structural steel in North America were A7 and A9. Note that SAE/AISI A7 and A9 tool steels are not the same as the obsolete ASTM A7 and A9 structural steels.

Steel Design, or more specifically, Structural Steel Design, is an area of structural engineering used to design steel structures. These structures include schools, houses, bridges, commercial centers, tall buildings, warehouses, aircraft, ships and stadiums. The design and use of steel frames are commonly employed in the design of steel structures. More advanced structures include steel plates and shells.

A specification often refers to a set of documented requirements to be satisfied by a material, design, product, or service. A specification is often a type of technical standard.

Cold-formed steel (CFS) is the common term for steel products shaped by cold-working processes carried out near room temperature, such as rolling, pressing, stamping, bending, etc. Stock bars and sheets of cold-rolled steel (CRS) are commonly used in all areas of manufacturing. The terms are opposed to hot-formed steel and hot-rolled steel.

A screw and a bolt are similar types of fastener typically made of metal and characterized by a helical ridge, called a male thread.

The Metal Building Manufacturers Association (MBMA) was founded in 1956 and promotes the design and construction of metal building systems in the low-rise, nonresidential building marketplace. A nonprofit trade organization, MBMA's headquarters is in Cleveland, Ohio. The organization consists of Building Systems members that are certified according to standards that have been set by the International Accreditation Service, and Associate members that work in the metal building industry. MBMA has a general manager, and it has a chairman and Board of Directors who are elected by members on an annual basis.

ASTM A325 is an ASTM International standard for heavy hex structural bolts, titled Standard Specification for Structural Bolts, Steel, Heat Treated, 120/105 ksi Minimum Tensile Strength. It defines mechanical properties for bolts that range from 1⁄2 to 1+1⁄2 inches in diameter.

ASTM A354 is an ASTM International standard that defines chemical and mechanical properties for alloy steel bolts, screws, studs, and other externally threaded fasteners. It is officially titled: Standard Specification for Quenched and Tempered Alloy Steel Bolts, Studs, and Other Externally Threaded Fasteners.

ASTM A490 and ASTM A490M are ASTM International standards for heavy hex structural bolts made from alloy steel. The imperial standard is officially titled Standard Specification for Structural Bolts, Alloy Steel, Heat Treated, 150 ksi Minimum Tensile Strength, while the metric standard (M) is titled Standard Specification for High-Strength Steel Bolts, Classes 10.9 and 10.9.3, for Structural Steel Joints.

A bolt is a form of threaded fastener with an external male thread requiring a matching pre-formed female thread such as a nut. Bolts are very closely related to screws.

Direct tension indicators, or DTIs, are single-use mechanical load cells used to indicate when the required tension has been achieved in structural fastener assemblies.

Adhesive bonding is a process by which two members of equal or dissimilar composition are joined. It is used in place of, or to complement other joining methods such mechanical fasting by the use nails, rivets, screws or bolts and many welding processes. The use of adhesives provides many advantages over welding and mechanical fastening in steel construction; however, many challenges still exist that have made the use of adhesives in structural steel components very limited.

Ducol or "D"-steel is the name of a number of high-strength low-alloy steels of varying composition, first developed from the early 1920s by the Scottish firm of David Colville & Sons, Motherwell.

John William Fisher is a professor emeritus of civil engineering.

References

- ↑ Specification for Structural Steel Buildings (ANSI/AISC 360-16) (PDF). American Institute of Steel Construction. July 7, 2016. p. 16.1–126.

- ↑ Brockenbrough, Roger; Schuster, Joseph (2018). "Appendix A4". Rehabilitation and Retrofit. Design Guide. Vol. 15 (2nd ed.). American Institute of Steel Construction. pp. 601–604.

- ↑ Research Council on Structural Connections (Jan 1951), Specifications for Assembly of Structural Joints Using High Tensile Steel Bolts, American Institute of Steel Construction

- ↑ Kulak, Geoffrey; Fisher, John; Struik, John (2001). Guide to Design Criteria for Bolted and Riveted Joints (PDF) (2nd ed.). American Institute of Steel Construction. p. 2. ISBN 1564240754.