Rebar, known when massed as reinforcing steel or steel reinforcement, is a tension device added to concrete to form reinforced concrete and reinforced masonry structures to strengthen and aid the concrete under tension. Concrete is strong under compression, but has low tensile strength. Rebar usually consists of steel bars which significantly increase the tensile strength of the structure. Rebar surfaces feature a continuous series of ribs, lugs or indentations to promote a better bond with the concrete and reduce the risk of slippage.

A rivet is a permanent mechanical fastener. Before being installed, a rivet consists of a smooth cylindrical shaft with a head on one end. The end opposite the head is called the tail. On installation, the deformed end is called the shop head or buck-tail.

A fastener or fastening is a hardware device that mechanically joins or affixes two or more objects together. In general, fasteners are used to create non-permanent joints; that is, joints that can be removed or dismantled without damaging the joining components. Steel fasteners are usually made of stainless steel, carbon steel, or alloy steel.

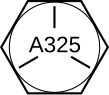

A bolted joint is one of the most common elements in construction and machine design. It consists of a male threaded fastener that captures and joins other parts, secured with a matching female screw thread. There are two main types of bolted joint designs: tension joints and shear joints.

Structural steel is a category of steel used for making construction materials in a variety of shapes. Many structural steel shapes take the form of an elongated beam having a profile of a specific cross section. Structural steel shapes, sizes, chemical composition, mechanical properties such as strengths, storage practices, etc., are regulated by standards in most industrialized countries.

Anchor bolts are used to connect structural and non-structural elements to concrete. The connection can be made by a variety of different components: anchor bolts, steel plates, or stiffeners. Anchor bolts transfer different types of load: tension forces and shear forces.

In solid mechanics, shearing forces are unaligned forces acting on one part of a body in a specific direction, and another part of the body in the opposite direction. When the forces are collinear, they are called tension forces or compression forces. Shear force can also be defined in terms of planes: "If a plane is passed through a body, a force acting along this plane is called a shear force or shearing force."

A screw is an externally helical threaded fastener capable of being tightened or released by a twisting force (torque) to the head. The most common uses of screws are to hold objects together and there are many forms for a variety of materials. Screws might be inserted into holes in assembled parts or a screw may form its own thread. The difference between a screw and a bolt is that the latter is designed to be tightened or released by torquing a nut.

A nut is a type of fastener with a threaded hole. Nuts are almost always used in conjunction with a mating bolt to fasten multiple parts together. The two partners are kept together by a combination of their threads' friction, a slight stretching of the bolt, and compression of the parts to be held together.

ASTM A992 steel is a structural steel alloy often used in the US for steel wide-flange and I beams. Like other carbon steels, the density of ASTM A992 steel is approximately 7850 kg/m3. ASTM A992 steel has the following minimum mechanical properties, according to ASTM specification A992/A992M. Tensile yield strength, 345 MPa (50 ksi); tensile ultimate strength, 450 MPa (65 ksi); strain to rupture in a 200-mm-long test specimen, 18%; strain to rupture in a 50-mm-long test specimen, 21%.

ISO 898 is an international standard that defines mechanical and physical properties for metric fasteners. This standard is the origin for other standards that define properties for similar metric fasteners, such as SAE J1199 and ASTM F568M. It is divided into five (nonconsecutive) parts:

ASTM F568M is an ASTM International standard for metric bolts, screws and studs that are used in general engineering applications. It is titled: Standard Specification for Carbon and Alloy Steel Externally Threaded Metric Fasteners. It defines mechanical properties for fasteners that range from M1.6 to 100 in diameter. The standard was withdrawn in 2012. and has been replaced by ISO 898-1

ASTM A354 is an ASTM International standard that defines chemical and mechanical properties for alloy steel bolts, screws, studs, and other externally threaded fasteners. It is officially titled: Standard Specification for Quenched and Tempered Alloy Steel Bolts, Studs, and Other Externally Threaded Fasteners.

ASTM A490 and ASTM A490M are ASTM International standards for heavy hex structural bolts made from alloy steel. The imperial standard is officially titled Standard Specification for Structural Bolts, Alloy Steel, Heat Treated, 150 ksi Minimum Tensile Strength, while the metric standard (M) is titled Standard Specification for High-Strength Steel Bolts, Classes 10.9 and 10.9.3, for Structural Steel Joints.

A threaded rod, also known as a stud, is a relatively long rod that is threaded on both ends; the thread may extend along the complete length of the rod. They are designed to be used in tension. Threaded rod in bar stock form is often called all-thread (ATR); other names include fully-threaded rod, redi-rod, continuously-threaded rod, and TFL rod.

A tube, or tubing, is a long hollow cylinder used for moving fluids or to protect electrical or optical cables and wires.

A bolt is an externally helical threaded fastener capable of being tightened or released by a twisting force (torque) to a matching nut. The bolt has an external male thread requiring a matching nut with a pre-formed female thread.

Direct tension indicators, or DTIs, are single-use mechanical load cells used to indicate when the required tension has been achieved in structural fastener assemblies.

Adhesive bonding is a process by which two members of equal or dissimilar composition are joined. It is used in place of, or to complement other joining methods such mechanical fasting by the use nails, rivets, screws or bolts and many welding processes. The use of adhesives provides many advantages over welding and mechanical fastening in steel construction; however, many challenges still exist that have made the use of adhesives in structural steel components very limited.

The Research Council on Structural Connections (RCSC) is a research organization focused on bolted structural connections. Their technical standard on this subject is cited in the US steel design code.

[11]

[11]