A pump is a device that moves fluids, or sometimes slurries, by mechanical action, typically converted from electrical energy into hydraulic or pneumatic energy.

Flow measurement is the quantification of bulk fluid movement. Flow can be measured using devices called flowmeters in various ways. The common types of flowmeters with industrial applications are listed below:

A check valve, non-return valve, reflux valve, retention valve, foot valve, or one-way valve is a valve that normally allows fluid to flow through it in only one direction.

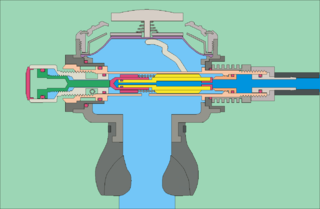

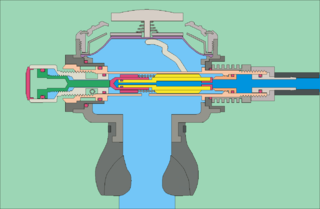

A diving regulator or underwater diving regulator is a pressure regulator that controls the pressure of breathing gas for underwater diving. The most commonly recognised application is to reduce pressurized breathing gas to ambient pressure and deliver it to the diver, but there are also other types of gas pressure regulator used for diving applications. The gas may be air or one of a variety of specially blended breathing gases. The gas may be supplied from a scuba cylinder carried by the diver, in which case it is called a scuba regulator, or via a hose from a compressor or high-pressure storage cylinders at the surface in surface-supplied diving. A gas pressure regulator has one or more valves in series which reduce pressure from the source, and use the downstream pressure as feedback to control the delivered pressure, or the upstream pressure as feedback to prevent excessive flow rates, lowering the pressure at each stage.

Plasma arc welding (PAW) is an arc welding process similar to gas tungsten arc welding (GTAW). The electric arc is formed between an electrode and the workpiece. The key difference from GTAW is that in PAW, the electrode is positioned within the body of the torch, so the plasma arc is separated from the shielding gas envelope. The plasma is then forced through a fine-bore copper nozzle which constricts the arc and the plasma exits the orifice at high velocities and a temperature approaching 28,000 °C (50,000 °F) or higher.

Manifold vacuum, or engine vacuum in a petrol engine is the difference in air pressure between the engine's intake manifold and Earth's atmosphere.

An orifice plate is a device used for measuring flow rate, for reducing pressure or for restricting flow.

In hydraulic systems, a fuse is a component which prevents the sudden loss of hydraulic fluid pressure. It is a safety feature, designed to allow systems to continue operating, or at least to not fail catastrophically, in the event of a system breach. It does this by stopping or greatly restricting the flow of hydraulic fluid through the fuse if the flow exceeds a threshold.

Originally the gas flow computer was a mechanical or later a pneumatic or hydraulic computing module, subsequently superseded in most applications by an electronic module, as the primary elements switched from transmitting the measured variables from pneumatic or hydraulic pressure signals to electric current as explosion-proof ) and then intrinsically safe transmitters became available, that simply provided a dedicated gas flow computer function. Today "gas flow computers" as such have become uncommon, since gas flow computing is a subfunction of a data acquisition and control program implemented with programmable logic controller (PLCs) and remote terminal unit (RTUs); with the rise of smart transmitters in the early 1980s, these functions have also been incorporated within the field transmitters themselves.

An infusion pump infuses fluids, medication or nutrients into a patient's circulatory system. It is generally used intravenously, although subcutaneous, arterial and epidural infusions are occasionally used.

Choked flow is a compressible flow effect. The parameter that becomes "choked" or "limited" is the fluid velocity.

A reservoir is an enlarged lake behind a dam, usually built to store fresh water, often doubling for hydroelectric power generation.

The flow coefficient of a device is a relative measure of its efficiency at allowing fluid flow. It describes the relationship between the pressure drop across an orifice valve or other assembly and the corresponding flow rate.

A pressure regulator is a valve that controls the pressure of a fluid to a desired value, using negative feedback from the controlled pressure. Regulators are used for gases and liquids, and can be an integral device with a pressure setting, a restrictor and a sensor all in the one body, or consist of a separate pressure sensor, controller and flow valve.

A flow limiter or flow restrictor is a device to restrict the flow of a fluid, in general a gas or a liquid. Some designs use single stage or multi-stage orifice plates to handle high and low flow rates. Flow limiters are often used in manufacturing plants as well as households. Safety is usually the main purpose of using a flow limiter. An example is manufacturing facilities and laboratories using flow limiters to prevent injury or death from noxious gases that are in use. The flow limiter prevents gases from causing injury or death by reducing its cross-sectional area where gas flows.

Rebreather diving is underwater diving using diving rebreathers, a class of underwater breathing apparatus which recirculate the breathing gas exhaled by the diver after replacing the oxygen used and removing the carbon dioxide metabolic product. Rebreather diving is practiced by recreational, military and scientific divers in applications where it has advantages over open circuit scuba, and surface supply of breathing gas is impracticable. The main advantages of rebreather diving are extended gas endurance, low noise levels, and lack of bubbles.

Diving procedures are standardised methods of doing things that are commonly useful while diving that are known to work effectively and acceptably safely. Due to the inherent risks of the environment and the necessity to operate the equipment correctly, both under normal conditions and during incidents where failure to respond appropriately and quickly can have fatal consequences, a set of standard procedures are used in preparation of the equipment, preparation to dive, during the dive if all goes according to plan, after the dive, and in the event of a reasonably foreseeable contingency. Standard procedures are not necessarily the only courses of action that produce a satisfactory outcome, but they are generally those procedures that experiment and experience show to work well and reliably in response to given circumstances. All formal diver training is based on the learning of standard skills and procedures, and in many cases the over-learning of the skills until the procedures can be performed without hesitation even when distracting circumstances exist. Where reasonably practicable, checklists may be used to ensure that preparatory and maintenance procedures are carried out in the correct sequence and that no steps are inadvertently omitted.

A Diving rebreather is an underwater breathing apparatus that absorbs the carbon dioxide of a diver's exhaled breath to permit the rebreathing (recycling) of the substantially unused oxygen content, and unused inert content when present, of each breath. Oxygen is added to replenish the amount metabolised by the diver. This differs from open-circuit breathing apparatus, where the exhaled gas is discharged directly into the environment. The purpose is to extend the breathing endurance of a limited gas supply, and, for covert military use by frogmen or observation of underwater life, to eliminate the bubbles produced by an open circuit system. A diving rebreather is generally understood to be a portable unit carried by the user, and is therefore a type of self-contained underwater breathing apparatus (scuba). A semi-closed rebreather carried by the diver may also be known as a gas extender. The same technology on a submersible or surface installation is more likely to be referred to as a life-support system.

The mechanism of diving regulators is the arrangement of components and function of gas pressure regulators used in the systems which supply breathing gases for underwater diving. Both free-flow and demand regulators use mechanical feedback of the downstream pressure to control the opening of a valve which controls gas flow from the upstream, high-pressure side, to the downstream, low-pressure side of each stage. Flow capacity must be sufficient to allow the downstream pressure to be maintained at maximum demand, and sensitivity must be appropriate to deliver maximum required flow rate with a small variation in downstream pressure, and for a large variation in supply pressure, without instability of flow. Open circuit scuba regulators must also deliver against a variable ambient pressure. They must be robust and reliable, as they are life-support equipment which must function in the relatively hostile seawater environment, and the human interface must be comfortable over periods of several hours.

A high pressure jet is a stream of pressurized fluid that is released from an environment at a significantly higher pressure than ambient pressure from a nozzle or orifice, due to operational or accidental release. In the field of safety engineering, the release of toxic and flammable gases has been the subject of many R&D studies because of the major risk that they pose to the health and safety of workers, equipment and environment. Intentional or accidental release may occur in an industrial settings like natural gas processing plants, oil refineries and hydrogen storage facilities.