This article needs additional citations for verification .(January 2021) |

Sable Chemical Industries Limited is the sole manufacturer of ammonium nitrate (NH4NO3) in Zimbabwe.

This article needs additional citations for verification .(January 2021) |

Sable Chemical Industries Limited is the sole manufacturer of ammonium nitrate (NH4NO3) in Zimbabwe.

Located in Kwekwe, Sable Chemical Industries Limited is Zimbabwe's sole manufacturer of nitrogen-based fertilizer, ammonium nitrate (AN). The company was incorporated in 1965 and started operations in 1969 using ammonia, a key raw material in the fertilizer making process, which at that time was imported through Sasol, South Africa. In 1972, Sable commissioned its own ammonia production facility via electrolysis of water. This saw the import quota reduce to 30% of total raw materials required to make AN. The nameplate capacity of the plant is 240,000 tonnes (240,000 long tons; 260,000 short tons) per annum of AN.

An air separation process is used to separate nitrogen from air for downstream use in the ammonia making process. By-products in the form of gaseous and liquid oxygen as well as small quantities of liquid nitrogen are formed. Five basic unit operations make up the air separation process: air compression, air purification, heat exchange, liquefaction and distillation. Nitrogen is compressed to 30 bar (3,000 kPa) prior to export to the ammonia making plant.

The purpose of the water electrolysis process is to produce hydrogen for use in ammonia making. The process consists of 14 electrolytic units. Electrolysis of water at Sable is a process whereby 6.5 kA direct current is applied across each electrolytic unit to separate water into hydrogen and oxygen both at 35 °C (95 °F) and 30 bar (3,000 kPa). An electrolyte consisting of 25% wt/wt potassium hydroxide, the other part being demineralised water, is used as feed to the electrolytic units. 90 MW (120,000 hp) are required to run all electrolytic units at capacity.

The ammonia making process is used for the manufacture of nitric acid and ammonium nitrate fertiliser. Using the Haber process, nitrogen from the air separation process and hydrogen water electrolysis are reacted over an iron catalyst at 320 bar (32,000 kPa) and 520 °C (968 °F) to produce ammonia gas. Ammonia is then liquefied and pumped to one of the two 1,000[ clarification needed ] storage spheres.

The nitric acid process produces nitric acid for use in making ammonium nitrate fertiliser. Using the Ostwald process, ammonia is vaporised and then oxidised over a 95% platinum and 5% rhodium catalyst at 930 °C (1,710 °F) and 6.5 bar (650 kPa) to form nitric oxide and superheated steam. The reaction gases are cooled to 38 °C (100 °F) before absorption by various heat recovery mechanisms. The cooled reaction gases are then passed through the bottom of an absorption column where a stream of air is added to oxidise nitric oxide to nitrogen dioxide. As the nitrogen dioxide passes up the column, it is absorbed by a stream of water flowing from the top of the absorption column to yield the desired product (57% nitric acid) which is then stored for downstream use.

The ammonium nitrate making process is a neutralisation process consisting of a reaction between ammonia and nitric acid. Ammonia is vaporised and then sparged through a proportionate amount of nitric acid to make an 83% wt/wt ammonium nitrate solution. The solution is concentrated to a 99% melt by vaporising water using two evaporators in series. 0.6% magnesium oxide is added to the melt. The melt is then pumped to the top of a prill tower into a prill pot from which it is sprayed against an approaching stream of air from the bottom of the tower, in the process making solid ammonium nitrate prills. These prills are then coated with a 0.15% dolomite-based coating agent prior to bagging and dispatch.

In 2010 Sable initiated the Clean Development Mechanism project in response to the ever growing concern over the environment, the first of its type in Zimbabwe.

"The Clean Development Mechanism (CDM), defined in Article 12 of the Protocol, allows a country with an emission-reduction or emission-limitation commitment under the Kyoto Protocol (Annex B Party) to implement an emission-reduction project in developing countries. Such projects can earn saleable certified emission reduction (CER) credits, each equivalent to one tonne of CO2, which can be counted towards meeting Kyoto targets." [1]

The project is intended to reduce the emissions of nitrous oxide, a crucial greenhouse gas, from one of the Sable processes. MGM Innova and DNV Climate Change Services, consultants in CDM projects development and validation, were engaged and carried out a detailed feasibility study up to the registration of the project with the CDM Executive Board in 2012 (Project 6483: Sable Chemicals Tertiary N2O Abatement Project in Zimbabwe, 2013). Standard Bank will fund the $6m required and will recover their investment through sale of CER credits.

Sable has been working on reengineering its ammonia producing process whose completion is predicted to come to light in the near future.[ when? ] This route will result in Sable retiring the energy consuming electrolysis process, thus releasing up to 115 MW (154,000 hp) into the grid for other electricity consumers. Gasification of coal to produce hydrogen will be used to substitute the current process of electrolysis of water.

Ammonia is an inorganic chemical compound of nitrogen and hydrogen with the formula NH3. A stable binary hydride and the simplest pnictogen hydride, ammonia is a colourless gas with a distinctive pungent smell. Biologically, it is a common nitrogenous waste, and it contributes significantly to the nutritional needs of terrestrial organisms by serving as a precursor to fertilisers. Around 70% of ammonia produced industrially is used to make fertilisers in various forms and composition, such as urea and diammonium phosphate. Ammonia in pure form is also applied directly into the soil.

The Haber process, also called the Haber–Bosch process, is the main industrial procedure for the production of ammonia. It converts atmospheric nitrogen (N2) to ammonia (NH3) by a reaction with hydrogen (H2) using a finely divided iron metal catalyst:

Nitrogen is a chemical element; it has symbol N and atomic number 7. Nitrogen is a nonmetal and the lightest member of group 15 of the periodic table, often called the pnictogens. It is a common element in the universe, estimated at seventh in total abundance in the Milky Way and the Solar System. At standard temperature and pressure, two atoms of the element bond to form N2, a colorless and odorless diatomic gas. N2 forms about 78% of Earth's atmosphere, making it the most abundant chemical species in air. Because of the volatility of nitrogen compounds, nitrogen is relatively rare in the solid parts of the Earth.

Nitrate is a polyatomic ion with the chemical formula NO−

3. Salts containing this ion are called nitrates. Nitrates are common components of fertilizers and explosives. Almost all inorganic nitrates are soluble in water. An example of an insoluble nitrate is bismuth oxynitrate.

Nitric acid is the inorganic compound with the formula HNO3. It is a highly corrosive mineral acid. The compound is colorless, but samples tend to acquire a yellow cast over time due to decomposition into oxides of nitrogen. Most commercially available nitric acid has a concentration of 68% in water. When the solution contains more than 86% HNO3, it is referred to as fuming nitric acid. Depending on the amount of nitrogen dioxide present, fuming nitric acid is further characterized as red fuming nitric acid at concentrations above 86%, or white fuming nitric acid at concentrations above 95%.

The Ostwald process is a chemical process used for making nitric acid (HNO3). The Ostwald process is a mainstay of the modern chemical industry, and it provides the main raw material for the most common type of fertilizer production. Historically and practically, the Ostwald process is closely associated with the Haber process, which provides the requisite raw material, ammonia (NH3).

Urea, also called carbamide, is an organic compound with chemical formula CO(NH2)2. This amide has two amino groups joined by a carbonyl functional group. It is thus the simplest amide of carbamic acid.

A fertilizer or fertiliser is any material of natural or synthetic origin that is applied to soil or to plant tissues to supply plant nutrients. Fertilizers may be distinct from liming materials or other non-nutrient soil amendments. Many sources of fertilizer exist, both natural and industrially produced. For most modern agricultural practices, fertilization focuses on three main macro nutrients: nitrogen (N), phosphorus (P), and potassium (K) with occasional addition of supplements like rock flour for micronutrients. Farmers apply these fertilizers in a variety of ways: through dry or pelletized or liquid application processes, using large agricultural equipment or hand-tool methods.

The nitrogen cycle is the biogeochemical cycle by which nitrogen is converted into multiple chemical forms as it circulates among atmospheric, terrestrial, and marine ecosystems. The conversion of nitrogen can be carried out through both biological and physical processes. Important processes in the nitrogen cycle include fixation, ammonification, nitrification, and denitrification. The majority of Earth's atmosphere (78%) is atmospheric nitrogen, making it the largest source of nitrogen. However, atmospheric nitrogen has limited availability for biological use, leading to a scarcity of usable nitrogen in many types of ecosystems.

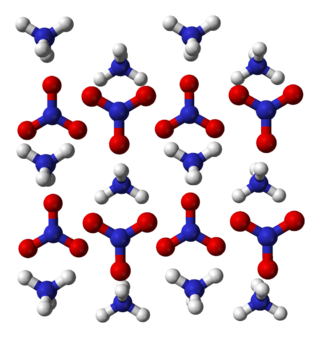

Ammonium nitrate is a chemical compound with the formula NH4NO3. It is a white crystalline salt consisting of ions of ammonium and nitrate. It is highly soluble in water and hygroscopic as a solid, although it does not form hydrates. It is predominantly used in agriculture as a high-nitrogen fertilizer.

Dinitrogen pentoxide is the chemical compound with the formula N2O5. It is one of the binary nitrogen oxides, a family of compounds that only contain nitrogen and oxygen. It exists as colourless crystals that sublime slightly above room temperature, yielding a colorless gas.

Calcium nitrate are inorganic compounds with the formula Ca(NO3)2(H2O)x. The anhydrous compound, which is rarely encountered, absorbs moisture from the air to give the tetrahydrate. Both anhydrous and hydrated forms are colourless salts. Hydrated calcium nitrate, also called Norgessalpeter (Norwegian salpeter), is mainly used as a component in fertilizers, but it has other applications. Nitrocalcite is the name for a mineral which is a hydrated calcium nitrate that forms as an efflorescence where manure contacts concrete or limestone in a dry environment as in stables or caverns. A variety of related salts are known including calcium ammonium nitrate decahydrate and calcium potassium nitrate decahydrate.

Magnesium nitrate refers to inorganic compounds with the formula Mg(NO3)2(H2O)x, where x = 6, 2, and 0. All are white solids. The anhydrous material is hygroscopic, quickly forming the hexahydrate upon standing in air. All of the salts are very soluble in both water and ethanol.

Ammonium nitrite is a chemical compound with the chemical formula [NH4]NO2. It is the ammonium salt of nitrous acid. It is composed of ammonium cations [NH4]+ and nitrite anions NO−2. It is not used in pure isolated form since it is highly unstable and decomposes into water and nitrogen, even at room temperature.

In atmospheric chemistry, NOx is shorthand for nitric oxide and nitrogen dioxide, the nitrogen oxides that are most relevant for air pollution. These gases contribute to the formation of smog and acid rain, as well as affecting tropospheric ozone.

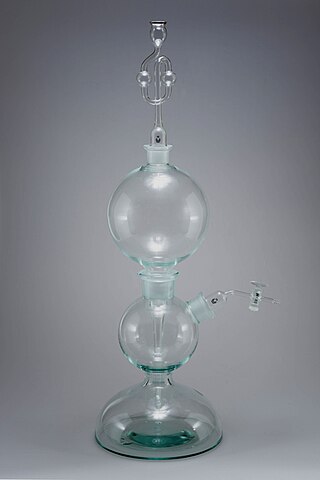

Kipp's apparatus, also called a Kipp generator, is an apparatus designed for preparation of small volumes of gases. It was invented around 1844 by the Dutch pharmacist Petrus Jacobus Kipp and widely used in chemical laboratories and for demonstrations in schools into the second half of the 20th century.

Ammonia production takes place worldwide, mostly in large-scale manufacturing plants that produce 183 million metric tonnes of ammonia (2021) annually. Leading producers are China (31.9%), Russia (8.7%), India (7.5%), and the United States (7.1%). 80% or more of ammonia is used as fertilizer. Ammonia is also used for the production of plastics, fibres, explosives, nitric acid, and intermediates for dyes and pharmaceuticals. The industry contributes 1% to 2% of global CO

2. Between 18–20 Mt of the gas is transported globally each year.

The chemical element nitrogen is one of the most abundant elements in the universe and can form many compounds. It can take several oxidation states; but the most common oxidation states are -3 and +3. Nitrogen can form nitride and nitrate ions. It also forms a part of nitric acid and nitrate salts. Nitrogen compounds also have an important role in organic chemistry, as nitrogen is part of proteins, amino acids and adenosine triphosphate.

The Birkeland–Eyde process was one of the competing industrial processes in the beginning of nitrogen-based fertilizer production. It is a multi-step nitrogen fixation reaction that uses electrical arcs to react atmospheric nitrogen (N2) with oxygen (O2), ultimately producing nitric acid (HNO3) with water. The resultant nitric acid was then used as a source of nitrate (NO3−) in the reaction which may take place in the presence of water or another proton acceptor.

Cobalt extraction refers to the techniques used to extract cobalt from its ores and other compound ores. Several methods exist for the separation of cobalt from copper and nickel. They depend on the concentration of cobalt and the exact composition of the ore used.