Related Research Articles

Incineration is a waste treatment process that involves the combustion of substances contained in waste materials. Industrial plants for waste incineration are commonly referred to as waste-to-energy facilities. Incineration and other high-temperature waste treatment systems are described as "thermal treatment". Incineration of waste materials converts the waste into ash, flue gas and heat. The ash is mostly formed by the inorganic constituents of the waste and may take the form of solid lumps or particulates carried by the flue gas. The flue gases must be cleaned of gaseous and particulate pollutants before they are dispersed into the atmosphere. In some cases, the heat that is generated by incineration can be used to generate electric power.

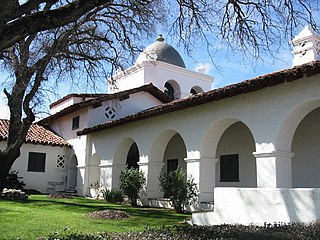

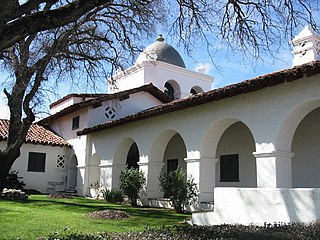

The Hacienda is the current designation for a historic hotel in Monterey County, near the town of Jolon, California. It was completed in 1930 for use by William Randolph Hearst as temporary housing for his employees and guests and headquarters for activities taking place on the surrounding land. The lodge building, designed by architect Julia Morgan, replaced and expanded upon an earlier wooden structure known as the Milpitas Ranch House which was destroyed by fire in the 1920s. The 1930 hotel has also been known as Milpitas Hacienda, Hacienda Guest Lodge and Milpitas Ranchhouse, under which name the property was placed in the National Register of Historic Places on December 2, 1977.

A furnace, referred to as a heater or boiler in British English, is an appliance used to generate heat for all or part of a building. Furnaces are mostly used as a major component of a central heating system. Furnaces are permanently installed to provide heat to an interior space through intermediary fluid movement, which may be air, steam, or hot water. Heating appliances that use steam or hot water as the fluid are normally referred to as a residential steam boilers or residential hot water boilers. The most common fuel source for modern furnaces in North America and much of Europe is natural gas; other common fuel sources include LPG, fuel oil, wood and in rare cases coal. In some areas electrical resistance heating is used, especially where the cost of electricity is low or the primary purpose is for air conditioning. Modern high-efficiency furnaces can be up to 98% efficient and operate without a chimney, with a typical gas furnace being about 80% efficient. Waste gas and heat are mechanically ventilated through either metal flue pipes or polyvinyl chloride (PVC) pipes that can be vented through the side or roof of the structure. Fuel efficiency in a gas furnace is measured in AFUE.

Gasification is a process that converts biomass- or fossil fuel-based carbonaceous materials into gases, including as the largest fractions: nitrogen (N2), carbon monoxide (CO), hydrogen (H2), and carbon dioxide (CO2). This is achieved by reacting the feedstock material at high temperatures (typically >700 °C), without combustion, via controlling the amount of oxygen and/or steam present in the reaction. The resulting gas mixture is called syngas (from synthesis gas) or producer gas and is itself a fuel due to the flammability of the H2 and CO of which the gas is largely composed. Power can be derived from the subsequent combustion of the resultant gas, and is considered to be a source of renewable energy if the gasified compounds were obtained from biomass feedstock.

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. Blast refers to the combustion air being supplied above atmospheric pressure.

Garbology is the study of modern refuse and trash as well as the use of trash cans, compactors and various types of trash can liners. It is a major source of information on the nature and changing patterns in modern refuse, and thereby, human society. Industries wishing to demonstrate that discards originating with their products are important in the trash stream are avid followers of this research, as are municipalities wishing to learn whether some parts of the trash they collect has any salable value.

In industrial chemistry, coal gasification is the process of producing syngas—a mixture consisting primarily of carbon monoxide (CO), hydrogen, carbon dioxide, methane, and water vapour —from coal and water, air and/or oxygen.

Municipal solid waste (MSW), commonly known as trash or garbage in the United States and rubbish in Britain, is a waste type consisting of everyday items that are discarded by the public. "Garbage" can also refer specifically to food waste, as in a garbage disposal; the two are sometimes collected separately. In the European Union, the semantic definition is 'mixed municipal waste,' given waste code 20 03 01 in the European Waste Catalog. Although the waste may originate from a number of sources that has nothing to do with a municipality, the traditional role of municipalities in collecting and managing these kinds of waste have produced the particular etymology 'municipal.'

Underground coal gasification (UCG) is an industrial process which converts coal into product gas. UCG is an in-situ gasification process, carried out in non-mined coal seams using injection of oxidants and steam. The product gas is brought to the surface through production wells drilled from the surface.

Waste-to-energy (WtE) or energy-from-waste (EfW) refers to a series of processes designed to convert waste materials into usable forms of energy, typically electricity or heat. As a form of energy recovery, WtE plays a crucial role in both waste management and sustainable energy production by reducing the volume of waste in landfills and providing an alternative energy source.

Fort Hunter Liggett is a United States Army post in Jolon, California, in southern Monterey County, California. The fort, named in 1941 after General Hunter Liggett, is primarily used as a training facility, where activities such as field maneuvers and live fire exercises are performed. It is roughly 25 miles northwest of Camp Roberts, California.

Plasma gasification is an extreme thermal process using plasma which converts organic matter into a syngas which is primarily made up of hydrogen and carbon monoxide. A plasma torch powered by an electric arc is used to ionize gas and catalyze organic matter into syngas, with slag remaining as a byproduct. It is used commercially as a form of waste treatment, and has been tested for the gasification of refuse-derived fuel, biomass, industrial waste, hazardous waste, and solid hydrocarbons, such as coal, oil sands, petcoke and oil shale.

An oil burner engine is a steam engine that uses oil as its fuel. The term is usually applied to a locomotive or ship engine that burns oil to heat water, to produce the steam which drives the pistons, or turbines, from which the power is derived.

Kaiser Steel was a steel company and integrated steel mill near Fontana, California. Industrialist Henry J. Kaiser founded the company on December 1, 1941, and workers fired up the plant's first blast furnace, named "Bess No. 1" after Kaiser's wife, on December 30, 1942. Then in August 1943, the plant would produce its first steel plate for the Pacific Coast shipbuilding industry amid World War II.

The Isle of Wight gasification facility is a municipal waste treatment plant in Newport, Isle of Wight. It entered the commissioning phase in autumn 2008, and was replaced by a moving grate incinerator in 2019.

Reworld, formerly Covanta, is a private energy-from-waste and industrial waste management services company headquartered in Morristown, New Jersey. Most of its revenue comes from operating incineration facilities that serve a secondary purpose as power plants that burn trash as fuel. Reworld charges a fee for waste disposal and sells the electricity and metal slag produced from waste incineration.

Camp Roberts is a California National Guard post in central California, located on both sides of the Salinas River in Monterey and San Luis Obispo counties, now run by the California Army National Guard. It was opened in 1941 and is named after Corporal Harold W. Roberts, a World War I Medal of Honor recipient. Nearby communities include San Miguel, Heritage Ranch, Oak Shores, and Bradley, all unincorporated. The nearest incorporated city is Paso Robles. Camp Roberts is roughly 25 miles southeast of Fort Hunter Liggett.

Combustion Resources, Inc. was a consulting company based in Provo, Utah, United States. It provided consulting services in the fields of fuel and combustion, such as testing of flow and mixing systems, reactor design, gas and particle sampling, gasification modeling, and shale oil extraction design and testing. The company was incorporated in 1995 as a spin-off from the Center for Advanced Combustion Engineering Research, joint collaboration between Brigham Young University and the University of Utah.

Plasma gasification is in commercial use as a waste-to-energy system that converts municipal solid waste, tires, hazardous waste, and sewage sludge into synthesis gas (syngas) containing hydrogen and carbon monoxide that can be used to generate power. Municipal-scale waste disposal plasma arc facilities have been in operation in Japan and China since 2002. No commercial implementations in Europe and North America have succeeded so far. The technology is characterized by the potential of very high level of destruction of the incoming waste, but low or negative net energy production and high operational costs.

All Power Labs (APL) is a renewable energy company based in Berkeley, California. The firm designs and manufactures biomass gasifiers and builds and markets small-scale (15–150 kW) electrical generators fueled by these gasifiers. By 2013, they reached an installed base of 500 machines in approximately 40 countries; As of 2015, APL employed 30 staff, including engineering, manufacturing, management, sales, and technical support staff, on the site of the former Shipyard, an approximately 20,000 sq.ft. facility that includes APL’s offices, R&D, manufacturing and production facilities.

References

- 1 2 3 "Sierra Energy wins federal grant to test trash-to-hydrogen technology". bizjournals.com. 8 October 2015. Retrieved 26 May 2023. (subscription required)

- ↑ "Sierra Energy refines garbage-to-fuel system". 16 March 2015.

- 1 2 Tullis, Paul (17 August 2013). "Trash into Gas, Efficiently? An Army Test May Tell". The New York Times.

- 1 2 3 Wilser, Jeff (December 4, 2019). "Recycling: Turning Trash Into Energy". Comstock's magazine. Retrieved 26 May 2023.

- ↑ "The future of waste-to-energy technology". CNBC . 8 February 2020.

- ↑ "This Davis company has raised a major financing round for its clean-energy technology". bizjournals.com. 15 June 2016. Retrieved 26 May 2023. (subscription required)

- 1 2 "U.S. Army is teaming up with a Davis startup to turn trash into energy". The Sacramento Bee. 26 March 2017. Retrieved 26 May 2023.

- 1 2 "Sierra Energy Closes $33 Million Series a Funding Led by Breakthrough Energy Ventures" (Press release).