This article has an unclear citation style .(August 2020) |

Silicon tombac (German : Siliziumtombak) is an alloy made of copper (80%), zinc (16%) and silicon (4%).

This article has an unclear citation style .(August 2020) |

Silicon tombac (German : Siliziumtombak) is an alloy made of copper (80%), zinc (16%) and silicon (4%).

The silicon content leads to a strengthening of the metal matrix. The appearance is similar to ordinary brass. Silicon tombac has good friction bearing characteristics and is corrosion resistant but is not resistant to ammonia atmosphere. The strength properties are largely retained at application temperatures up to 200 °C. [1] It is a special alloy in terms of the combination of casting process and casting temperature. In most cases, parts made of silicon tombac, are produced through the high pressure die casting process, which is normally specialized on metals with relatively low melting temperatures. But in this case the temperature melting range of silicon tombac is in the area of 950 to 1000 °C, which is relatively high for casting into permanent moulds. The advantage is the productivity of this highly automated casting process. The disadvantage is the temperature stress of the surface of the permanent mould, so that the lifetime of these moulds is limited.

High pressure die cast silicon tombac is often used as an alternative for investment cast steel parts, because the mechanical strength is comparable (500 MPa), [1] but the production process is more efficient. There can be found a break-even-point when comparing both processes, whereas the advantages of high pressure die casting regularly predominate at high unit numbers (for instance greater than 5000 units) to produce. [2] This alloy has outstanding casting properties and good strength properties, [3] which is required for the die casting process. It is often chosen for small to medium size parts in terms of casting metal volume. For large parts often investment casting of steels is applied because of the lower material cost.

The silicon content limits the solubility of zinc in copper in the α-phase. In the given alloy the maximum amount of silicon at a very high zinc content is added. The consequence is that the α-phase crystallized silicon supersaturated when it comes to high cooling rates of the alloy. As a result the α-solid solution does not disintegrate, which leads to the described high mechanical properties.

An alloy is a mixture of chemical elements of which in most cases at least one is a metallic element, although it is also sometimes used for mixtures of elements; herein only metallic alloys are described. Most alloys are metallic and show good electrical conductivity, ductility, opacity, and luster, and may have properties that differ from those of the pure elements such as increased strength or hardness. In some cases, an alloy may reduce the overall cost of the material while preserving important properties. In other cases, the mixture imparts synergistic properties such as corrosion resistance or mechanical strength.

Brass is an alloy of copper and zinc, in proportions which can be varied to achieve different colours and mechanical, electrical, acoustic and chemical properties, but copper typically has the larger proportion, generally 66% copper and 34% zinc. In use since prehistoric times, it is a substitutional alloy: atoms of the two constituents may replace each other within the same crystal structure.

Metallurgy is a domain of materials science and engineering that studies the physical and chemical behavior of metallic elements, their inter-metallic compounds, and their mixtures, which are known as alloys.

Solder is a fusible metal alloy used to create a permanent bond between metal workpieces. Solder is melted in order to wet the parts of the joint, where it adheres to and connects the pieces after cooling. Metals or alloys suitable for use as solder should have a lower melting point than the pieces to be joined. The solder should also be resistant to oxidative and corrosive effects that would degrade the joint over time. Solder used in making electrical connections also needs to have favorable electrical characteristics.

In metalworking and jewelry making, casting is a process in which a liquid metal is delivered into a mold that contains a negative impression of the intended shape. The metal is poured into the mold through a hollow channel called a sprue. The metal and mold are then cooled, and the metal part is extracted. Casting is most often used for making complex shapes that would be difficult or uneconomical to make by other methods.

In printing, type metal refers to the metal alloys used in traditional typefounding and hot metal typesetting. Historically, type metal was an alloy of lead, tin and antimony in different proportions depending on the application, be it individual character mechanical casting for hand setting, mechanical line casting or individual character mechanical typesetting and stereo plate casting. The proportions used are in the range: lead 50‒86%, antimony 11‒30% and tin 3‒20%. Antimony and tin are added to lead for durability while reducing the difference between the coefficients of expansion of the matrix and the alloy. Apart from durability, the general requirements for type-metal are that it should produce a true and sharp cast, and retain correct dimensions and form after cooling down. It should also be easy to cast, at reasonable low melting temperature, iron should not dissolve in the molten metal, and mould and nozzles should stay clean and easy to maintain. Today, Monotype machines can utilize a wide range of different alloys. Mechanical linecasting equipment uses alloys that are close to eutectic.

Brazing is a metal-joining process in which two or more metal items are joined by melting and flowing a filler metal into the joint, with the filler metal having a lower melting point than the adjoining metal.

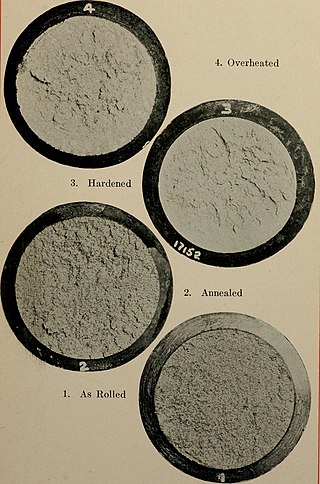

Powder metallurgy (PM) is a term covering a wide range of ways in which materials or components are made from metal powders. PM processes are sometimes used to reduce or eliminate the need for subtractive processes in manufacturing, lowering material losses and reducing the cost of the final product. This occurs especially often with small metal parts, like gears for small machines. Some porous products, allowing liquid or gas to permeate them, are produced in this way. They are also used when melting a material is impractical, due to it having a high melting point, or an alloy of two mutually insoluble materials, such as a mixture of copper and graphite.

Refractory metals are a class of metals that are extraordinarily resistant to heat and wear. The expression is mostly used in the context of materials science, metallurgy and engineering. The definition of which elements belong to this group differs. The most common definition includes five elements: two of the fifth period and three of the sixth period. They all share some properties, including a melting point above 2000 °C and high hardness at room temperature. They are chemically inert and have a relatively high density. Their high melting points make powder metallurgy the method of choice for fabricating components from these metals. Some of their applications include tools to work metals at high temperatures, wire filaments, casting molds, and chemical reaction vessels in corrosive environments. Partly due to the high melting point, refractory metals are stable against creep deformation to very high temperatures.

Aluminium–silicon alloys or Silumin is a general name for a group of lightweight, high-strength aluminium alloys based on an aluminum–silicon system (AlSi) that consist predominantly of aluminum - with silicon as the quantitatively most important alloying element. Pure AlSi alloys cannot be hardened, the commonly used alloys AlSiCu and AlSiMg can be hardened. The hardening mechanism corresponds to that of AlCu and AlMgSi.

Carbon steel is a steel with carbon content from about 0.05 up to 2.1 percent by weight. The definition of carbon steel from the American Iron and Steel Institute (AISI) states:

Tool steel is any of various carbon steels and alloy steels that are particularly well-suited to be made into tools and tooling, including cutting tools, dies, hand tools, knives, and others. Their suitability comes from their distinctive hardness, resistance to abrasion and deformation, and their ability to hold a cutting edge at elevated temperatures. As a result, tool steels are suited for use in the shaping of other materials, as for example in cutting, machining, stamping, or forging.

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminium, magnesium, lead, pewter, and tin-based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used.

Gun metal, also known as red brass in the United States, is a type of bronze – an alloy of copper, tin, and zinc. Proportions vary but 88% copper, 8–10% tin, and 2–4% zinc is an approximation. Originally used chiefly for making guns, it has largely been replaced by steel for that purpose. Gunmetal casts and machines well, and is resistant to corrosion from steam and salt water. It is used to make steam and hydraulic castings, valves, gears, statues, and various small objects, such as buttons. It has a tensile strength of 221 megapascals (32,100 psi) to 310 megapascals (45,000 psi), a specific gravity of 8.7, a Brinell hardness of 65 to 74, and a melting point of around 1,000 degrees Celsius.

Spin casting, also known as centrifugal rubber mold casting (CRMC), is a method of utilizing inertia to produce castings from a rubber mold. Typically, a disc-shaped mold is spun along its central axis at a set speed. The casting material, usually molten metal or liquid thermoset plastic, is then poured in through an opening at the top-center of the mold. The filled mold then continues to spin as the metal solidifies.

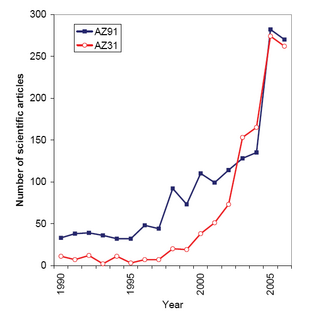

Magnesium alloys are mixtures of magnesium with other metals, often aluminium, zinc, manganese, silicon, copper, rare earths and zirconium. Magnesium alloys have a hexagonal lattice structure, which affects the fundamental properties of these alloys. Plastic deformation of the hexagonal lattice is more complicated than in cubic latticed metals like aluminium, copper and steel; therefore, magnesium alloys are typically used as cast alloys, but research of wrought alloys has been more extensive since 2003. Cast magnesium alloys are used for many components of modern cars and have been used in some high-performance vehicles; die-cast magnesium is also used for camera bodies and components in lenses.

An aluminium alloy (UK/IUPAC) or aluminum alloy is an alloy in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin, nickel and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable. About 85% of aluminium is used for wrought products, for example rolled plate, foils and extrusions. Cast aluminium alloys yield cost-effective products due to the low melting point, although they generally have lower tensile strengths than wrought alloys. The most important cast aluminium alloy system is Al–Si, where the high levels of silicon (4–13%) contribute to give good casting characteristics. Aluminium alloys are widely used in engineering structures and components where light weight or corrosion resistance is required.

Semi-solid metal casting (SSM) is a near net shape variant of die casting. The process is used today with non-ferrous metals, such as aluminium, copper, and magnesium. It can work with higher temperature alloys that lack suitable die materials. The process combines the advantages of casting and forging.The process is named after the fluid property thixotropy, which is the phenomenon that allows this process to work. Thixotropic fluids flow when sheared, but thicken when standing. The potential for this type of process was first recognized in the early 1970s. Its three variants are thixocasting, rheocasting, and thixomolding. SIMA refers to a specialized process to prepare aluminum alloys for thixocasting using hot and cold working.

Permanent mold casting is a metal casting process that employs reusable molds, usually made from metal. The most common process uses gravity to fill the mold, however gas pressure or a vacuum are also used. A variation on the typical gravity casting process, called slush casting, produces hollow castings. Common casting metals are aluminium, magnesium, and copper alloys. Other materials include tin, zinc, and lead alloys and iron and steel are also cast in graphite molds.

Mangalloy, also called manganese steel or Hadfield steel, is an alloy steel containing an average of around 13% manganese. Mangalloy is known for its high impact strength and resistance to abrasion once in its work-hardened state.