A mandrel is one of the following:

A chuck is a specialized type of clamp used to hold an object with radial symmetry, especially a cylinder. In drills and mills it holds the rotating tool whereas in lathes it holds the rotating workpiece. On a lathe the chuck is mounted on the spindle which rotates within the headstock. For some purposes an additional chuck may be mounted on the non-rotating tailstock.

A machine taper is a system for securing cutting tools or toolholders in the spindle of a machine tool or power tool. A male member of conical form fits into the female socket, which has a matching taper of equal angle.

A wedge is a triangular shaped tool, and is a portable inclined plane, and one of the six classical simple machines. It can be used to separate two objects or portions of an object, lift up an object, or hold an object in place. It functions by converting a force applied to its blunt end into forces perpendicular (normal) to its inclined surfaces. The mechanical advantage of a wedge is given by the ratio of the length of its slope to its width. Although a short wedge with a wide angle may do a job faster, it requires more force than a long wedge with a narrow angle.

The shank is the end of a drill bit grasped by the chuck of a drill. The cutting edges of the drill bit contact the workpiece, and are connected via the shaft with the shank, which fits into the chuck. In many cases a general-purpose arrangement is used, such as a bit with cylindrical shaft and shank in a three-jaw chuck which grips a cylindrical shank tightly. Different shank and chuck combination can deliver improved performance, such as allowing higher torque, greater centering accuracy, or moving the bit, but not the chuck, with a hammer action.

A lathe center, often shortened to center, is a tool that has been ground to a point to accurately position a workpiece on an axis. They usually have an included angle of 60°, but in heavy machining situations an angle of 75° is used.

A tuning peg is used to hold a string in the pegbox of a stringed instrument. It may be made of ebony, rosewood, boxwood or other material. Some tuning pegs are ornamented with shell, metal, or plastic inlays, beads (pips) or rings. A peg has a grip or knob on it to allow it to be turned.

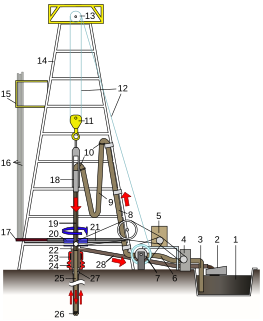

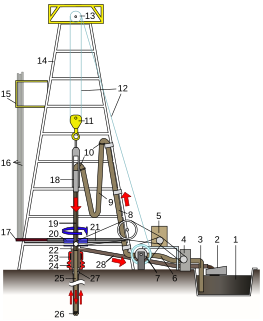

A blowout preventer (BOP) is a large, specialized valve or similar mechanical device, used to seal, control and monitor oil and gas wells to prevent blowouts, the uncontrolled release of crude oil and/or natural gas from a well. They are usually installed in stacks of other valves.

In the oil and gas industries, coiled tubing refers to a very long metal pipe, normally 1 to 3.25 in in diameter which is supplied spooled on a large reel. It is used for interventions in oil and gas wells and sometimes as production tubing in depleted gas wells. Coiled tubing is often used to carry out operations similar to wirelining. The main benefits over wireline are the ability to pump chemicals through the coil and the ability to push it into the hole rather than relying on gravity. Pumping can be fairly self-contained, almost a closed system, since the tube is continuous instead of jointed pipe. For offshore operations, the 'footprint' for a coiled tubing operation is generally larger than a wireline spread, which can limit the number of installations where coiled tubing can be performed and make the operation more costly. A coiled tubing operation is normally performed through the drilling derrick on the oil platform, which is used to support the surface equipment, although on platforms with no drilling facilities a self-supporting tower can be used instead. For coiled tubing operations on sub-sea wells a mobile offshore drilling unit (MODU) e.g. semi-submersible, drillship etc. has to be utilized to support all the surface equipment and personnel, whereas wireline can be carried out from a smaller and cheaper intervention vessel. Onshore, they can be run using smaller service rigs, and for light operations a mobile self-contained coiled tubing rig can be used.

A production packer is a standard component of the completion hardware of oil or gas wells used to provide a seal between the outside of the production tubing and the inside of the casing, liner, or wellbore wall.

See snubber for a device used to suppress ("snub") voltage transients in electrical systems

The chande is a drum used in the traditional and classical music of South India and particularly in Yakshagana theatre art of Karnataka. It follows the Yakshagana Tala system. The rhythms are based on pre-classical music forms that Karnataka Sangeta and Hindustani Sangeetha are based on. There are different varieties of this instrument; two major varieties being the Badagu Thittu Chande and the Thenku Thittu Chande. The latter can also be spelled chenda and is used exclusively in the art forms of southern coastal Karnataka and Kerala. This article deals with Badagu Thittu Chande, used exclusively in Yakshagana of Karnataka. The chande used in Badagu Thittu is structurally and acoustically different from the chenda used in Kerala.

Oilfield terminology refers to the jargon used by those working in fields within and related to the upstream segment of the petroleum industry. It includes words and phrases describing professions, equipment, and procedures specific to the industry. It may also include slang terms used by oilfield workers to describe the same.

A rotary table is a mechanical device on a drilling rig that provides clockwise rotational force to the drill string to facilitate the process of drilling a borehole. Rotary speed is the number of times the rotary table makes one full revolution in one minute (rpm).

Tripping pipe is the physical act of pulling the drill string out of the wellbore and then running it back in. This is done by physically breaking out or disconnecting every other 2 or 3 joints of drill pipe at a time and racking them vertically in the derrick. When feasible the driller will start each successive trip on a different "break" so that after several trips fresh pipe dope will have been applied to every segment of the drill string.

A screw extractor is a tool for removing broken or seized screws. There are two types: one has a spiral flute structure, commonly called an easy out after the trademarked name EZ-Out; the other has a straight flute structure. Screw extractors are intentionally made of hard, brittle steel, and, if too much torque is applied, can break off inside the screw that is being removed. Since the extractor is an extremely hard material, and a typical home shop drill bit will not be able to drill into it, a larger element of difficulty is added to the original screw extraction project. One way to avoid this added difficulty is to drill a hole completely through the screw. Thus, if the fastener breaks, a punch can be used to drive out the easy out from the screw, via the back, or end, of the fastener.

Pipe recovery is a specific wireline operation used in the oil and gas industry, when the drill string becomes stuck downhole. Stuck pipe prevents the drill rig from continuing operations. This results in costly downtime, ranging anywhere from $10,000-1,000,000 per day of downtime, therefore it is critical to resolve the problem as quickly as possible. Pipe recovery is the process by which the location of the stuck pipe is identified, and the free pipe is separated from the stuck pipe. This allows fishing tools to subsequently be run down hole to latch onto and remove the stuck pipe.

A Tubing spider is a tool used primarily in the oil industry for gripping the drill string while assembling or reassembling parts of the string.