Configuration management (CM) is a process for establishing and maintaining consistency of a product's performance, functional, and physical attributes with its requirements, design, and operational information throughout its life. The CM process is widely used by military engineering organizations to manage changes throughout the system lifecycle of complex systems, such as weapon systems, military vehicles, and information systems. Outside the military, the CM process is also used with IT service management as defined by ITIL, and with other domain models in the civil engineering and other industrial engineering segments such as roads, bridges, canals, dams, and buildings.

KNX is an open standard for commercial and domestic building automation. KNX devices can manage lighting, blinds and shutters, HVAC, security systems, energy management, audio video, white goods, displays, remote control, etc. KNX evolved from three earlier standards; the European Home Systems Protocol (EHS), BatiBUS, and the European Installation Bus. It can use twisted pair, powerline, RF, or IP links. On this network, the devices form distributed applications and tight interaction is possible. This is implemented via interworking models with standardised datapoint types and objects, modelling logical device channels.

Wireless sensor networks (WSNs) refer to networks of spatially dispersed and dedicated sensors that monitor and record the physical conditions of the environment and forward the collected data to a central location. WSNs can measure environmental conditions such as temperature, sound, pollution levels, humidity and wind.

Data security means protecting digital data, such as those in a database, from destructive forces and from the unwanted actions of unauthorized users, such as a cyberattack or a data breach.

Threat modeling is a process by which potential threats, such as structural vulnerabilities or the absence of appropriate safeguards, can be identified and enumerated, and countermeasures prioritized. The purpose of threat modeling is to provide defenders with a systematic analysis of what controls or defenses need to be included, given the nature of the system, the probable attacker's profile, the most likely attack vectors, and the assets most desired by an attacker. Threat modeling answers questions like “Where am I most vulnerable to attack?”, “What are the most relevant threats?”, and “What do I need to do to safeguard against these threats?”.

A test fixture is an environment used to consistently test some item, device, or piece of software. Test fixtures can be found when testing electronics, software and physical devices.

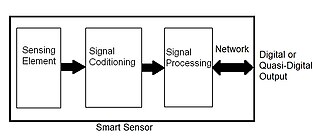

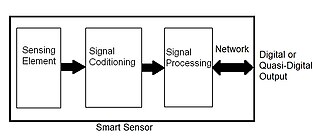

A smart transducer is an analog or digital transducer, actuator or sensor combined with a processing unit and a communication interface.

The Internet of things (IoT) describes physical objects with sensors, processing ability, software and other technologies that connect and exchange data with other devices and systems over the Internet or other communications networks. Internet of things has been considered a misnomer because devices do not need to be connected to the public internet, they only need to be connected to a network and be individually addressable.

The Advanced Learning and Research Institute (ALaRI), a faculty of informatics, was established in 1999 at the University of Lugano with the mission of promoting research and education in embedded systems. The Faculty of Informatics within very few years has become one of the Switzerland major destinations for teaching and research, ranking third after the two Federal Institutes of Technology, Zurich and Lausanne.

A smart object is an object that enhances the interaction with not only people but also with other smart objects. Also known as smart connected products or smart connected things (SCoT), they are products, assets and other things embedded with processors, sensors, software and connectivity that allow data to be exchanged between the product and its environment, manufacturer, operator/user, and other products and systems. Connectivity also enables some capabilities of the product to exist outside the physical device, in what is known as the product cloud. The data collected from these products can be then analyzed to inform decision-making, enable operational efficiencies and continuously improve the performance of the product.

A cyber-physicalsystem (CPS) or intelligent system is a computer system in which a mechanism is controlled or monitored by computer-based algorithms. In cyber-physical systems, physical and software components are deeply intertwined, able to operate on different spatial and temporal scales, exhibit multiple and distinct behavioral modalities, and interact with each other in ways that change with context. CPS involves transdisciplinary approaches, merging theory of cybernetics, mechatronics, design and process science. The process control is often referred to as embedded systems. In embedded systems, the emphasis tends to be more on the computational elements, and less on an intense link between the computational and physical elements. CPS is also similar to the Internet of Things (IoT), sharing the same basic architecture; nevertheless, CPS presents a higher combination and coordination between physical and computational elements.

In our modern society, computerized or digital control systems have been used to reliably automate many of the industrial operations that we take for granted, from the power plant to the automobiles we drive. However, the complexity of these systems and how the designers integrate them, the roles and responsibilities of the humans that interact with the systems, and the cyber security of these highly networked systems have led to a new paradigm in research philosophy for next-generation control systems. Resilient Control Systems consider all of these elements and those disciplines that contribute to a more effective design, such as cognitive psychology, computer science, and control engineering to develop interdisciplinary solutions. These solutions consider things such as how to tailor the control system operating displays to best enable the user to make an accurate and reproducible response, how to design in cybersecurity protections such that the system defends itself from attack by changing its behaviors, and how to better integrate widely distributed computer control systems to prevent cascading failures that result in disruptions to critical industrial operations. In the context of cyber-physical systems, resilient control systems are an aspect that focuses on the unique interdependencies of a control system, as compared to information technology computer systems and networks, due to its importance in operating our critical industrial operations.

The Fourth Industrial Revolution, 4IR, or Industry 4.0, conceptualizes rapid change to technology, industries, and societal patterns and processes in the 21st century due to increasing interconnectivity and smart automation. The term has been used widely in scientific literature, and in 2015 was popularized by Klaus Schwab, the World Economic Forum Founder and Executive chairman. Schwab asserts that the changes seen are more than just improvements to efficiency, but express a significant shift in industrial capitalism.

A digital twin is a digital representation of an intended or actual real-world physical product, system, or process that serves as the effectively indistinguishable digital counterpart of it for practical purposes, such as simulation, integration, testing, monitoring, and maintenance. The digital twin has been intended from its initial introduction to be the underlying premise for Product Lifecycle Management and exists throughout the entire lifecycle, create, build, operate/support, and dispose, of the physical entity it represents. Since information is granular, the digital twin representation is determined by the value based use cases it is created to implement. The digital twin can and does often exist before there is a physical entity. The use of a digital twin in the create phase allows the intended entity's entire lifecycle to be modeled and simulated. A digital twin of an existing entity can, but must not necessarily, be used in real time and regularly synchronized with the corresponding physical system.

Smart manufacturing is a broad category of manufacturing that employs computer-integrated manufacturing, high levels of adaptability and rapid design changes, digital information technology, and more flexible technical workforce training. Other goals sometimes include fast changes in production levels based on demand, optimization of the supply chain, efficient production and recyclability. In this concept, as smart factory has interoperable systems, multi-scale dynamic modelling and simulation, intelligent automation, strong cyber security, and networked sensors.

The industrial internet of things (IIoT) refers to interconnected sensors, instruments, and other devices networked together with computers' industrial applications, including manufacturing and energy management. This connectivity allows for data collection, exchange, and analysis, potentially facilitating improvements in productivity and efficiency as well as other economic benefits. The IIoT is an evolution of a distributed control system (DCS) that allows for a higher degree of automation by using cloud computing to refine and optimize the process controls.

Eyes of Things (EoT) is the name of a project funded by the European Union’s Horizon 2020 Research and Innovation Programme under grant agreement number 643924. The purpose of the project, which is funded under the Smart Cyber-physical systems topic, is to develop a generic hardware-software platform for embedded, efficient, computer vision, including deep learning inference.

The Internet of Military Things (IoMT) is a class of Internet of things for combat operations and warfare. It is a complex network of interconnected entities, or "things", in the military domain that continually communicate with each other to coordinate, learn, and interact with the physical environment to accomplish a broad range of activities in a more efficient and informed manner. The concept of IoMT is largely driven by the idea that future military battles will be dominated by machine intelligence and cyber warfare and will likely take place in urban environments. By creating a miniature ecosystem of smart technology capable of distilling sensory information and autonomously governing multiple tasks at once, the IoMT is conceptually designed to offload much of the physical and mental burden that warfighters encounter in a combat setting.

Internet of vehicles (IoV) is a network of vehicles equipped with sensors, software, and the technologies that mediate between these with the aim of connecting & exchanging data over the Internet according to agreed standards. IoV evolved from Vehicular Ad Hoc Networks and is expected to ultimately evolve into an "Internet of autonomous vehicles". It is expected that IoV will be one of the enablers for an autonomous, connected, electric, and shared (ACES) Future Mobility.

NGSI-LD is an information model and API for publishing, querying and subscribing to context information. It is meant to facilitate the open exchange and sharing of structured information between different stakeholders. It is used across application domains such as smart cities, smart industry, smart agriculture, and more generally for the Internet of things, cyber-physical systems, systems of systems and digital twins.