An inductor, also called a coil, choke, or reactor, is a passive two-terminal electrical component that stores energy in a magnetic field when electric current flows through it. An inductor typically consists of an insulated wire wound into a coil.

A transformer is a passive electrical device that transfers electrical energy from one electrical circuit to another, or multiple circuits. A varying current in any one coil of the transformer produces a varying magnetic flux in the transformer's core, which induces a varying electromotive force across any other coils wound around the same core. Electrical energy can be transferred between separate coils without a metallic (conductive) connection between the two circuits. Faraday's law of induction, discovered in 1831, describes the induced voltage effect in any coil due to a changing magnetic flux encircled by the coil.

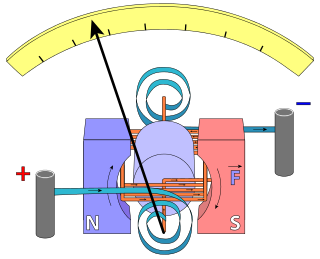

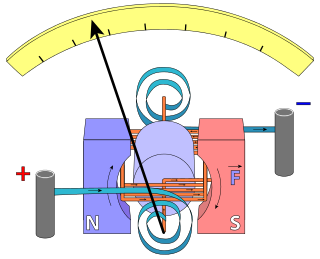

A multimeter or a multitester, also known as a VOM (volt-ohm-milliammeter), is an electronic measuring instrument that combines several measurement functions in one unit. A typical multimeter can measure voltage, current, and resistance. Analog multimeters use a microammeter with a moving pointer to display readings. Digital multimeters have a numeric display, and may also show a graphical bar representing the measured value. Digital multimeters have rendered analog multimeters obsolete, because they are now lower cost, higher precision, and more physically robust.

Electromagnetic or magnetic induction is the production of an electromotive force across an electrical conductor in a changing magnetic field.

A magnetometer is a device that measures magnetism—the direction, strength, or relative change of a magnetic field at a particular location. The measurement of the magnetization of a magnetic material is an example. A compass is one such device, one that measures the direction of an ambient magnetic field, in this case, the Earth's magnetic field.

Eddy currents are loops of electrical current induced within conductors by a changing magnetic field in the conductor according to Faraday's law of induction. Eddy currents flow in closed loops within conductors, in planes perpendicular to the magnetic field. They can be induced within nearby stationary conductors by a time-varying magnetic field created by an AC electromagnet or transformer, for example, or by relative motion between a magnet and a nearby conductor. The magnitude of the current in a given loop is proportional to the strength of the magnetic field, the area of the loop, and the rate of change of flux, and inversely proportional to the resistivity of the material. When graphed, these circular currents within a piece of metal look vaguely like eddies or whirlpools in a liquid.

A magnetic core is a piece of magnetic material with a high magnetic permeability used to confine and guide magnetic fields in electrical, electromechanical and magnetic devices such as electromagnets, transformers, electric motors, generators, inductors, magnetic recording heads, and magnetic assemblies. It is made of ferromagnetic metal such as iron, or ferrimagnetic compounds such as ferrites. The high permeability, relative to the surrounding air, causes the magnetic field lines to be concentrated in the core material. The magnetic field is often created by a current-carrying coil of wire around the core.

Sound Transmission Class is an integer rating of how well a building partition attenuates airborne sound. In the US, it is widely used to rate interior partitions, ceilings, floors, doors, windows and exterior wall configurations. Outside the US, the Sound Reduction Index (SRI) ISO index is used. The STC rating very roughly reflects the decibel reduction of noise that a partition can provide. The STC is useful for evaluating annoyance due to speech sounds, but not music or machinery noise as these sources contain more low frequency energy than speech.

Electrical steel is an iron alloy tailored to produce specific magnetic properties: small hysteresis area resulting in low power loss per cycle, low core loss, and high permeability.

In electrical and electronic engineering, a current clamp, also known as current probe, is an electrical device with jaws which open to allow clamping around an electrical conductor. This allows measurement of the current in a conductor without the need to make physical contact with it, or to disconnect it for insertion through the probe.

In-circuit test (ICT) is an example of white box testing where an electrical probe tests a populated printed circuit board (PCB), checking for shorts, opens, resistance, capacitance, and other basic quantities which will show whether the assembly was correctly fabricated. It may be performed with a bed of nails type test fixture and specialist test equipment, or with a fixtureless in-circuit test setup.

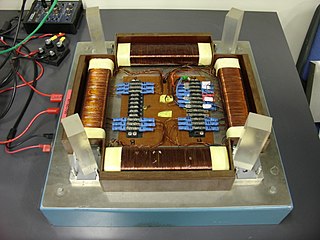

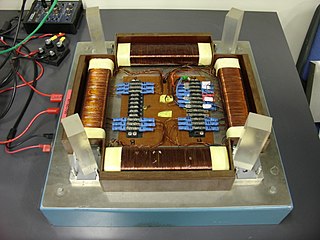

An Epstein frame or Epstein square is a standardised measurement device for measuring the magnetic properties of soft magnetic materials, especially used for testing of electrical steels.

An optical power meter (OPM) is a device used to measure the power in an optical signal. The term usually refers to a device for testing average power in fiber optic systems. Other general purpose light power measuring devices are usually called radiometers, photometers, laser power meters, light meters or lux meters.

A heat flux sensor is a transducer that generates an electrical signal proportional to the total heat rate applied to the surface of the sensor. The measured heat rate is divided by the surface area of the sensor to determine the heat flux.

A measuring instrument is a device for measuring a physical quantity. In the physical sciences, quality assurance, and engineering, measurement is the activity of obtaining and comparing physical quantities of real-world objects and events. Established standard objects and events are used as units, and the process of measurement gives a number relating the item under study and the referenced unit of measurement. Measuring instruments, and formal test methods which define the instrument's use, are the means by which these relations of numbers are obtained. All measuring instruments are subject to varying degrees of instrument error and measurement uncertainty. These instruments may range from simple objects such as rulers and stopwatches to electron microscopes and particle accelerators. Virtual instrumentation is widely used in the development of modern measuring instruments.

A dielectric withstand test is an electrical test performed on a component or product to determine the effectiveness of its insulation. The test may be between mutually insulated sections of a part or energized parts and electrical ground. The test is a means to qualify a device's ability to operate safely during rated electrical conditions. If the current through a device under test is less than a specified limit at the required test potential and time duration, the device meets the dielectric withstand requirement. A dielectric withstand test may be done as a factory test on new equipment, or may be done on apparatus already in service as a routine maintenance test.

The stacking factor is a measure used in electrical transformer design and some other electrical machines. It is the ratio of the effective cross-sectional area of the transformer core to the physical cross-sectional area of the transformer core. The two are different because of the way cores are constructed.

In electrical engineering, current sensing is any one of several techniques used to measure electric current. The measurement of current ranges from picoamps to tens of thousands of amperes. The selection of a current sensing method depends on requirements such as magnitude, accuracy, bandwidth, robustness, cost, isolation or size. The current value may be directly displayed by an instrument, or converted to digital form for use by a monitoring or control system.

Electromagnetically induced acoustic noise , electromagnetically excited acoustic noise, or coil whine is audible sound directly produced by materials vibrating under the excitation of electromagnetic forces. Some examples of this noise include the mains hum, hum of transformers, the whine of some rotating electric machines, or the buzz of fluorescent lamps. The hissing of high voltage transmission lines is due to corona discharge, not magnetism.