Related Research Articles

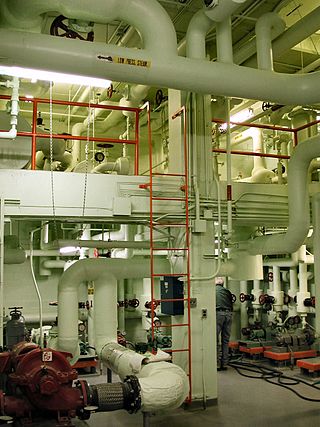

Plumbing is any system that conveys fluids for a wide range of applications. Plumbing uses pipes, valves, plumbing fixtures, tanks, and other apparatuses to convey fluids. Heating and cooling (HVAC), waste removal, and potable water delivery are among the most common uses for plumbing, but it is not limited to these applications. The word derives from the Latin for lead, plumbum, as the first effective pipes used in the Roman era were lead pipes.

A flange is a protruded ridge, lip or rim, either external or internal, that serves to increase strength ; for easy attachment/transfer of contact force with another object ; or for stabilizing and guiding the movements of a machine or its parts. Flanges are often attached using bolts in the pattern of a bolt circle.

A plumbing fixture is an exchangeable device which can be connected to a plumbing system to deliver and drain water.

In modern plumbing, a drain-waste-vent is a system that allows air to enter the plumbing system to maintain proper air pressure to enable the removal of sewage and greywater from a dwelling. Drain refers to water produced at fixtures such as sinks, and showers; waste refers to water from toilets. As the water runs down, proper venting is required to allow water to flow freely, and avoid a vacuum from being created. As the water runs down air must be allowed into the waste pipe either through a roof vent (external), or an internal vent.

A compression fitting is a fitting used in plumbing and electrical conduit systems to join two tubes or thin-walled pipes together. In instances where two pipes made of dissimilar materials are to be joined, the fittings will be made of one or more compatible materials appropriate for the connection. Compression fittings for attaching tubing (piping) commonly have compression rings, called ferrules or olives, in them, and are sometimes referred to as flareless fittings. There are also flare fittings that do not require ferrules/olives.

Cross-linked polyethylene, commonly abbreviated PEX, XPE or XLPE, is a form of polyethylene with cross-links. It is used predominantly in building services pipework systems, hydronic radiant heating and cooling systems, domestic water piping, insulation for high tension electrical cables, and baby play mats. It is also used for natural gas and offshore oil applications, chemical transportation, and transportation of sewage and slurries. PEX is an alternative to polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC) or copper tubing for use as residential water pipes.

A pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases (fluids), slurries, powders and masses of small solids. It can also be used for structural applications; hollow pipe is far stiffer per unit weight than solid members.

The Lead and Copper Rule (LCR) is a United States federal regulation that limits the concentration of lead and copper allowed in public drinking water at the consumer's tap, as well as limiting the permissible amount of pipe corrosion occurring due to the water itself. The U.S. Environmental Protection Agency (EPA) first issued the rule in 1991 pursuant to the Safe Drinking Water Act (SDWA). The EPA promulgated the regulations following studies that concluded that copper and lead have an adverse effect on individuals. The LCR limits the levels of these metals in water through improving water treatment centers, determining copper and lead levels for customers who use lead plumbing parts, and eliminating the water source as a source of lead and copper. If the lead and copper levels exceed the "action levels", water suppliers are required to educate their consumers on how to reduce exposure to lead. In a 2005 report EPA stated that the LCR requirements had been effective in 96 percent of systems serving at least 3,300 people.

A threaded pipe is a pipe with screw-threaded ends for assembly.

Thread seal tape is a polytetrafluoroethylene (PTFE) film tape commonly used in plumbing for sealing pipe threads. The tape is sold cut to specific widths and wound on a spool, making it easy to wind around pipe threads. Thread seal tape lubricates, allowing for a deeper seating of the threads, and it helps prevent the threads from seizing when being unscrewed. The tape also works as a deformable filler and thread lubricant, helping to seal the joint without hardening or making it more difficult to tighten, and instead making it easier to tighten. It also protects the threads of both pieces from direct contact with each other and physical wear and helps seal and prevent leaks from the connection.

Victaulic is a developer and manufacturer of mechanical pipe joining systems, and the originator of the grooved pipe couplings joining system. The firm is a global company with 15 major manufacturing facilities, 28 branches, and over 3600 employees worldwide. Currently, its headquarters is located in Easton, Pennsylvania.

In piping and plumbing, a coupling is a very short length of pipe or tube, with a socket at one or both ends that allows two pipes or tubes to be joined, welded (steel), brazed or soldered together.

A fitting or adapter is used in pipe systems to connect sections of pipe or tube, adapt to different sizes or shapes, and for other purposes such as regulating fluid flow. These fittings are used in plumbing to manipulate the conveyance of fluids such as water for potatory, irrigational, sanitary, and refrigerative purposes, gas, petroleum, liquid waste, or any other liquid or gaseous substances required in domestic or commercial environments, within a system of pipes or tubes, connected by various methods, as dictated by the material of which these are made, the material being conveyed, and the particular environmental context in which they will be used, such as soldering, mortaring, caulking, Plastic welding, welding, friction fittings, threaded fittings, and compression fittings.

A pipefitter or steamfitter is a tradesman who installs, assembles, fabricates, maintains, and repairs mechanical piping systems. Pipefitters usually begin as helpers or apprentices. Journeyman pipefitters deal with industrial/commercial/marine piping and heating/cooling systems. Typical industrial process pipe is under high pressure, which requires metals such as carbon steel, stainless steel, and many different alloy metals fused together through precise cutting, threading, grooving, bending, and welding. A plumber concentrates on lower pressure piping systems for sewage and potable tap water in the industrial, commercial, institutional, or residential atmosphere. Utility piping typically consists of copper, PVC, CPVC, polyethylene, and galvanized pipe, which is typically glued, soldered, or threaded. Other types of piping systems include steam, ventilation, hydraulics, chemicals, fuel, and oil.

Push-to-pull, push-to-connect, push-in, push-fit, or instant fittings are a type of easily removed compression fitting or quick connect fitting that allows an air line to be attached, nominally without the use of tools. These fittings act similar to the way regular compression fittings work, but use a resilient O-ring for sealing, and a grip ring to hold the tube in place.

Viega is a family owned international manufacturer of Plumbing and HVAC solutions. Viega sells PEX for Radiant heating and plumbing systems along with copper, stainless, and metal alloy pipe along with mechanical pressure fitting products.

Soldering is a process of joining two metal surfaces together using a filler metal called solder. The soldering process involves heating the surfaces to be joined and melting the solder, which is then allowed to cool and solidify, creating a strong and durable joint.

Copper tubing is most often used for heating systems and as a refrigerant line in HVAC systems. Copper tubing is slowly being replaced by PEX tubing in hot and cold water applications. There are two basic types of copper tubing, soft copper and rigid copper. Copper tubing is joined using flare connection, compression connection, pressed connection, or solder. Copper offers a high level of corrosion resistance but is becoming very costly.

Pegler Yorkshire is a British manufacturer of valves and other engineering products. It is part of the Flow Control division of Aalberts.

A wiped joint is a form of soldered joint used to join lead pipework.

References

- ↑ Yorkshire , retrieved 2020-08-10.

- ↑ Boyce, Robert Michael; Masterman, Arnold (2005), Plumbing: a practical guide for level 2, Nelson Thornes, p. 151, ISBN 978-0-7487-9275-7.