A lathe is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis.

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the workpiece and provide a guided movement of the parts of the machine. Thus, the relative movement between the workpiece and the cutting tool is controlled or constrained by the machine to at least some extent, rather than being entirely "offhand" or "freehand". It is a power-driven metal cutting machine which assists in managing the needed relative motion between cutting tool and the job that changes the size and shape of the job material.

Metalworking is the process of shaping and reshaping metals in order to create useful objects, parts, assemblies, and large scale structures. As a term, it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges, down to precise engine parts and delicate jewelry.

Joseph Clement was a British engineer and industrialist, chiefly remembered as the maker of Charles Babbage's first difference engine, between 1824 and 1833.

In machining, a metal lathe or metalworking lathe is a large class of lathes designed for precisely machining relatively hard materials. They were originally designed to machine metals; however, with the advent of plastics and other materials, and with their inherent versatility, they are used in a wide range of applications, and a broad range of materials. In machining jargon, where the larger context is already understood, they are usually simply called lathes, or else referred to by more-specific subtype names. These rigid machine tools remove material from a rotating workpiece via the movements of various cutting tools, such as tool bits and drill bits.

Brown & Sharpe is a division of Hexagon AB, a Swedish multinational corporation focused mainly on metrological tools and technology. During the 19th and 20th centuries, Brown & Sharpe was one of the best-known and most influential machine tool builders and was a leading manufacturer of instruments for machinists. Its reputation and influence were such that its name is often considered to be inseparably paired with certain industrial standards that it helped establish, including:

A machine shop or engineering workshop is a room, building, or company where machining, a form of subtractive manufacturing, is done. In a machine shop, machinists use machine tools and cutting tools to make parts, usually of metal or plastic. A machine shop can be a small business or a portion of a factory, whether a toolroom or a production area for manufacturing. The building construction and the layout of the place and equipment vary, and are specific to the shop; for instance, the flooring in one shop may be concrete, or even compacted dirt, and another shop may have asphalt floors. A shop may be air-conditioned or not; but in other shops it may be necessary to maintain a controlled climate. Each shop has its own tools and machinery which differ from other shops in quantity, capability and focus of expertise.

Bryant is a brand of machine tools headquartered in Springfield, Vermont. Acquired by Fives in 2015, the Bryant product line specializes in the grinding field, building grinding machines with computer numerical control (CNC).

Haas Automation, Inc is an American machine tool builder headquartered in Oxnard, California. The company designs and manufactures lower cost machine tools and specialized accessory tooling, mostly computer numerically controlled (CNC) equipment, such as vertical machining centers and horizontal machining centers, lathes/turning centers, and rotary tables and indexers. Most of its products are manufactured at the company's main facility in Oxnard. The company is also involved in motorsports: it owns the Haas F1 Team and is a co-owner of Stewart-Haas Racing in NASCAR. Haas is one of the largest machine tool builders in the world by total unit volume.

Bridgeport stands as a legendary name in the realm of vertical milling machines and machining centers, boasting a long standing legacy that dates back to 1938 under the name of Bridgeport Machines Inc.. Originally sold in 1938 to Textron Inc., this iconic brand embarked on a new chapter when it joined forces with Hardinge, Inc. in 2004. The legacy continued as Bridgeport captured headlines again in 2023, with its latest acquisition by the manufacturing conglomerate InCompass™, marking yet another milestone in its storied journey of engineering excellence and innovation.

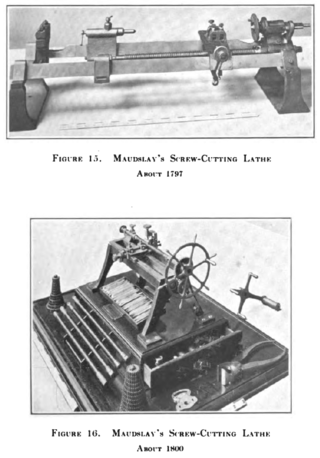

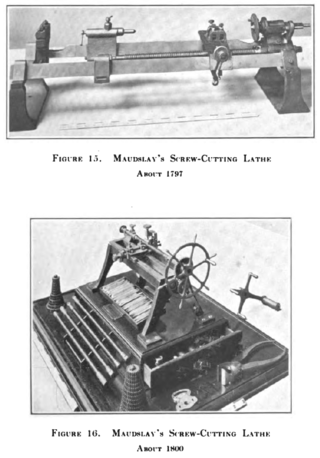

A screw-cutting lathe is a machine capable of cutting very accurate screw threads via single-point screw-cutting, which is the process of guiding the linear motion of the tool bit in a precisely known ratio to the rotating motion of the workpiece. This is accomplished by gearing the leadscrew to the spindle with a certain gear ratio for each thread pitch. Every degree of spindle rotation is matched by a certain distance of linear tool travel, depending on the desired thread pitch.

Yamazaki Mazak Corporation is a Japanese machine tool builder based in Oguchi, Japan. In the most of the world they are referred to as Mazak.

Georg Fischer comprises four divisions GF Piping Systems, GF Building Flow Solutions, GF Casting Solutions, and GF Machining Solutions. Founded in 1802, the corporation is headquartered in Switzerland and is present in 45 countries, with 187 companies, 76 of them production facilities. Its over 19 800 employees generated sales of over CHF 4 billion in 2018. GF offers pipes for the safe transport of liquids and gases, lightweight casting components in vehicles, and high-precision manufacturing technologies.

Boxford Lathe was a brand of lathes produced by Denford Machine Tools from 1946 until 1952. The original factory was in Box Tree Mills, Wheatley, Halifax, West Yorkshire, England. Denford Machine Tools also produced other metalworking tools including precision measuring tools such as an optical comparator. The lathes and other tools were marketed under the name "Box-Ford". The name appears to be a portmanteau of "Box Tree Mills" and the founder's surname, "Denford". In 1952, the founder, Horace Denford, sold the company with Boxfords continuing at Halifax and Denfords in Brighouse.

In 1887, Richard Knight LeBlond founded the R. K. LeBlond Machine Tool Company in Cincinnati, Ohio to manufacture metal cutting lathes. The LeBlond Aircraft Engine Corporation was formed as a subsidiary in 1928. As a result of a joint venture with Makino Milling Machine, LeBlond Makino Machine Tool Company was formed in 1981. In 1996, LeBlond Makino Machine Tool Company changed its name to Makino. Then in 1997, LeBlond Lathe Parts was founded to focus on the service and support of all LeBlond lathe equipment manufactured since 1887. In 1998, after acquiring the W. F. & John Barnes Company, the company's name was changed to LeBlond Ltd to reflect a broader business purpose. LeBlond continued its acquisition strategy by acquiring the Standard Modern lathe service parts business in 1999. The Johnson Press and Deka Drill service parts businesses were acquired from South Bend Lathe in 2001 and the South Bend Lathe and Dynablast parts businesses in March, 2002. LeBlond's product support team had collectively 160 years of service with LeBlond Machine Tool Company, LeBlond Makino and Makino.

In metalworking and woodworking, an automatic lathe is a lathe with an automatically controlled cutting process. Automatic lathes were first developed in the 1870s and were mechanically controlled. From the advent of NC and CNC in the 1950s, the term automatic lathe has generally been used for only mechanically controlled lathes, although some manufacturers market Swiss-type CNC lathes as 'automatic'.

Okuma Corporation is a machine tool builder based in Ōguchi, Aichi Prefecture, Japan. It has global market share in CNC machine tools such as CNC lathes, machining centers, and turn-mill machining centers. The company also offers FA products and servomotors.

Cosby Donald Philipps Smallpeice was an English engineer involved in design of precision and production lathes, and pneumatic tools and hoists. He created the company Martonair, and on its flotation in 1966 he founded The Smallpeice Trust to provide opportunities for engineering students. Much of the history of Cosby Smallpeice is covered in a publication by The Smallpeice Trust titled "A Smallpeice of History", which documents the history of the founder, the trust, and its ongoing training programmes.

Edward Payson Bullard Jr. was an American engineer, president of the Bullard Machine Tool Company for 40 years, and inventor. He was awarded the ASME Medal in 1937.

Artillerie-Inrichtingen was a Dutch state-owned artillery, small arms, and munitions company which also produced machine tools and was founded in 1679 in Delft, Netherlands. The company was split in 1973 with its defense related businesses becoming Eurometaal and its civilian manufacturing becoming Hembrug Machine Tools. During its years of operation as Artillerie Inrichtingen, the company manufactured armaments and an array of other industrial outputs for the Dutch Army and the Royal Dutch East Indies Army (KNIL).