A programmable logic controller (PLC) or programmable controller is an industrial computer that has been ruggedized and adapted for the control of manufacturing processes, such as assembly lines, machines, robotic devices, or any activity that requires high reliability, ease of programming, and process fault diagnosis.

Irrigation is the practice of applying controlled amounts of water to land to help grow crops, landscape plants, and lawns. Irrigation has been a key aspect of agriculture for over 5,000 years and has been developed by many cultures around the world. Irrigation helps to grow crops, maintain landscapes, and revegetate disturbed soils in dry areas and during times of below-average rainfall. In addition to these uses, irrigation is also employed to protect crops from frost, suppress weed growth in grain fields, and prevent soil consolidation. It is also used to cool livestock, reduce dust, dispose of sewage, and support mining operations. Drainage, which involves the removal of surface and sub-surface water from a given location, is often studied in conjunction with irrigation.

Automation describes a wide range of technologies that reduce human intervention in processes, mainly by predetermining decision criteria, subprocess relationships, and related actions, as well as embodying those predeterminations in machines. Automation has been achieved by various means including mechanical, hydraulic, pneumatic, electrical, electronic devices, and computers, usually in combination. Complicated systems, such as modern factories, airplanes, and ships typically use combinations of all of these techniques. The benefit of automation includes labor savings, reducing waste, savings in electricity costs, savings in material costs, and improvements to quality, accuracy, and precision.

A thermostat is a regulating device component which senses the temperature of a physical system and performs actions so that the system's temperature is maintained near a desired setpoint.

Mechatronics engineering, also called mechatronics, is an interdisciplinary branch of engineering that focuses on the integration of mechanical engineering, electrical engineering, electronic engineering and software engineering, and also includes a combination of robotics, computer science, telecommunications, systems, control, automation and product engineering.

HVAC equipment needs a control system to regulate the operation of a heating and/or air conditioning system. Usually a sensing device is used to compare the actual state with a target state. Then the control system draws a conclusion what action has to be taken.

A cam timer or drum sequencer is an electromechanical system for controlling a sequence of events automatically. It resembles a music box with movable pins, controlling electrical switches instead of musical notes.

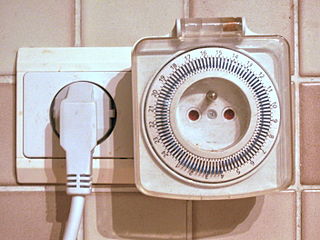

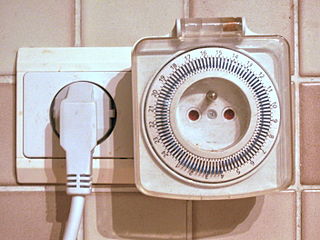

A timer or countdown timer is a type of clock that starts from a specified time duration and stops upon reaching 00:00. An example of a simple timer is an hourglass. Commonly, a timer triggers an alarm when it ends. A timer can be implemented through hardware or software. Stopwatches operate in the opposite direction, upwards from 00:00, measuring elapsed time since a given time instant. Time switches are timers that control an electric switch.

In control theory, an open-loop controller, also called a non-feedback controller, is a control loop part of a control system in which the control action is independent of the "process output", which is the process variable that is being controlled. It does not use feedback to determine if its output has achieved the desired goal of the input command or process setpoint.

A rain sensor or rain switch is a switching device activated by rainfall. There are two main applications for rain sensors. The first is a water conservation device connected to an automatic irrigation system that causes the system to shut down in the event of rainfall. The second is a device used to protect the interior of an automobile from rain and to support the automatic mode of windscreen wipers.

An irrigation controller is a device to operate automatic irrigation systems such as lawn sprinklers and drip irrigation systems. Most controllers have a means of setting the frequency of irrigation, the start time, and the duration of watering. Some controllers have additional features such as multiple programs to allow different watering frequencies for different types of plants, rain delay settings, input terminals for sensors such as rain and freeze sensors, soil moisture sensors, weather data, remote operation, etc.

A solenoid valve is an electromechanically operated valve.

An irrigation sprinkler is a device used to irrigate (water) agricultural crops, lawns, landscapes, golf courses, and other areas. They are also used for cooling and for the control of airborne dust. Sprinkler irrigation is the method of applying water in a controlled manner in way similar to rainfall. The water is distributed through a network that may consist of pumps, valves, pipes, and sprinklers.

The following outline is provided as an overview of and topical guide to automation:

Brake-by-wire technology in the automotive industry is the ability to control brakes through electronic means, without a mechanical connection that transfers force to the physical braking system from a driver input apparatus such as a pedal or lever.

A time switch is a device that operates an electric switch controlled by a timer.

A water timer is an electromechanical device that, when placed on a water line, increases or decreases the water flow through the use of an electro-mechanically actuated ball valve or embedded (solenoid) valve. It is used in conjunction with irrigation sprinklers to form an automated or non-automated sprinkler system, capable of administering precise amounts of water, at a regular basis. A water flow timer using a ball valve contains an electric motor with gears to stop or start the water flow by turning a perforated ball within the water flow line. The gearbox in a ball valve timer makes a rumbling sound when actuated. The solenoid type switching timers contain a solenoid that relieves pressure on a diaphragm in the water-flow tube or moves a stopper into the water flow area to regulate flow. The solenoid type uses no gears and makes a tapping sound when the solenoid is activated. Battery powered garden hose timers are the most commonly seen water timers and are seen in two types, the ball valve timer that is actuated by a motor with gears, and the diaphragm timer that is actuated by a solenoid. The solenoid/diaphragm timer uses more battery power throughout the "on" cycle because the solenoid must be actuated the entire time that the water flow is "on". The ball valve timer using the motor and gear actuator only uses more battery power during the few seconds that motor is used to turn the water flow on or off.

Partial stroke testing is a technique used in a control system to allow the user to test a percentage of the possible failure modes of a shut down valve without the need to physically close the valve. PST is used to assist in determining that the safety function will operate on demand. PST is most often used on high integrity emergency shutdown valves (ESDVs) in applications where closing the valve will have a high cost burden yet proving the integrity of the valve is essential to maintaining a safe facility. In addition to ESDVs PST is also used on high integrity pressure protection systems or HIPPS. Partial stroke testing is not a replacement for the need to fully stroke valves as proof testing is still a mandatory requirement.

Rain Clox was the trade name given to a series of electromechanical irrigation controllers produced by the Rain Bird Corporation from 1962 to the late 2000s (decade), and were largely responsible for giving rise to the widespread use of automatic irrigation. The first model was the ME11AB, capable of running 11 stations on two schedules. A scaled-down residential model, the RC-8, was formally introduced in 1968 and was marketed as the "first appliance for the garden". The Los Angeles Times reported in 1967 that architects incorporated the RC-8 into a suburban housing development in Glendale, California, planning on adding the cost of the system to the mortgage. The controllers were used in controlled experiments of swine waste lagoon systems. The product line would later range from compact 3-station mechanical units to 23-station multi-program devices.

The first automatic timer, the dashpot timer has been used in many different machines and has many variations. Pneumatic, hydraulic-action, and mercury displacement timers. Being used in a variety of things such as printing presses, motors, and even irrigation systems, the dashpot timer has seen many applications. Even in modern times with electrical and digital timers, these old mechanical timers are still in use due to their simplicity and ability to function in tough environments.